技術理論:技術…實用…有趣的自動化工業解決方案

在 DELCO,我們了解客戶滿意度的重要性,並努力滿足每位客戶的獨特需求。作為可靠的閥門供應商,我們致力於提供優質的客戶服務和高品質的產品,以確保最佳的性能和使用壽命。透過選擇 DELCO 作為您值得信賴的控制空氣供應商,您可以受益於專門設計用於滿足您的要求的客製化閥門組件,從而提高效率並減少停機時間。

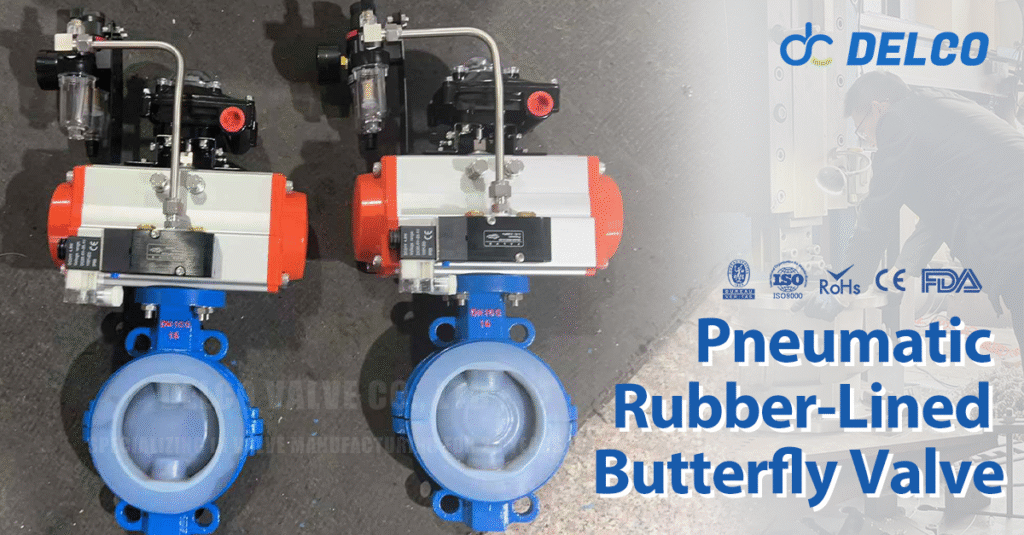

Maintenance and Care Guide for Pneumatic Butterfly Valves

氣動蝶閥 are commonly used in industrial fluid control, and their fast response and efficient operation have made them a core piece of equipment in a variety of industries. However, in order to ensure the long-term stable operation of the valve, regular maintenance and repair are essential. In this article, DELCO Valve will introduce the common problems, maintenance methods and specific recommendations for extending the life of pneumatic butterfly valves.

Common Causes of Failure

- Gate Stuck: Due to impurities or deposits in the medium, the gate cannot open or close smoothly.

- Seal wear: after long-term use, the soft seals may fail due to aging at high pressure or high temperature.

- Pneumatic actuator failure: Insufficient pressure from the air source or wear inside the actuator leads to slow action.

- Corrosion problems: Exposed to corrosive media or environment, the valve body and key components may be damaged.

Routine Maintenance and Care Methods

- Regular cleaning: Remove dirt and deposits on the surface and inside of the valve, especially under conditions of handling media containing particles, to avoid accumulation of impurities leading to jamming.

- Lubricate critical parts: Apply lubricant to the shaft and seals regularly to minimize wear and improve smooth operation.

- Inspect seals: Regularly inspect soft seals for wear and replace them when deterioration or cracks are found to prevent media leakage.

- Test pneumatic actuators: Test the sensitivity of pneumatic actuators to ensure rapid action response and check whether the air source pressure is stable.

- Anti-corrosion protection: For valves exposed to corrosive environments, it is recommended to apply anti-corrosion coating on a regular basis, or use corrosion-resistant materials (such as stainless steel or rubber-lined materials).

Suggestions to Extend the Service Life of the Valve

- Follow the manufacturer’s operating instructions and avoid using the valve beyond its design pressure or temperature range.

- Operate the valve periodically, even during prolonged shutdowns, to prevent components from failing due to prolonged quiescence.

- Monitor changes in operating conditions and promptly adjust valve settings to accommodate changes in media pressure, temperature or flow rate.

Key Precautions

- Ensure that the environment around the valve is clean, to avoid dust or impurities into the pneumatic actuator.

- Keep commonly used seals and lubricants on hand for quick replacement and maintenance.

- Complex faults need to contact professional technicians for diagnosis and repair.

結論

Regular cleaning, lubrication, seal inspection and testing of pneumatic actuators can significantly extend the life of Pneumatic Butterfly Valves and reduce the incidence of failure. Proper maintenance not only improves equipment operating efficiency, but also reduces long-term operating costs.

聯絡 DELCO 以取得快速報價

如果您對閥門有疑問或想獲得報價,請隨時聯絡我們,我們將在 6 小時內回覆。電話 +86 159 8960 2972,WhatsApp +86 159 8960 2972 或發送電子郵件至 [email protected]。

在 DELCO,我們了解客戶滿意度的重要性,並努力滿足每位客戶的獨特需求。作為可靠的控制閥供應商,我們致力於提供優質的客戶服務和高品質的產品,以確保最佳性能和使用壽命。選擇 DELCO 作為您值得信賴的控制閥供應商,您可以受益於專門設計用於滿足您的要求的客製化閥門組件,從而提高效率並減少停機時間。

此外,我們在電子壓力調節器方面的競爭性定價使您能夠提供一流的解決方案。作為領先的控制閥製造商之一,我們很自豪地提供可靠的閥門,這些閥門不僅符合行業標準,而且還能為您企業的整體盈利能力做出貢獻。透過與 DELCO 合作,您可以放心,因為您為公司的長期成功做出了明智的選擇。