技術理論:技術…實用…有趣的自動化工業解決方案

在 DELCO,我們了解客戶滿意度的重要性,並努力滿足每位客戶的獨特需求。作為可靠的閥門供應商,我們致力於提供優質的客戶服務和高品質的產品,以確保最佳的性能和使用壽命。透過選擇 DELCO 作為您值得信賴的控制空氣供應商,您可以受益於專門設計用於滿足您的要求的客製化閥門組件,從而提高效率並減少停機時間。

電動蝶閥、電動球閥、電動二通閥的拆卸步驟

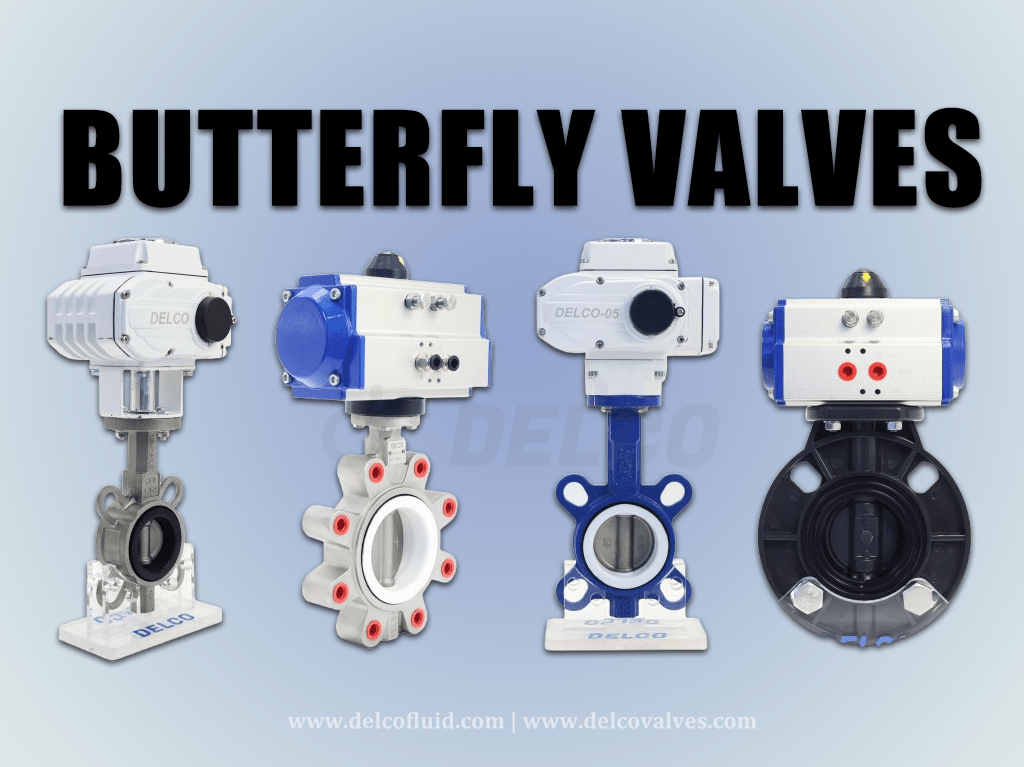

在工業和建築領域中,電動閥門的應用十分廣泛且至關重要。 Delcofluid 閥門製造商非常清楚正確拆卸對於電動蝶閥、電動球閥和電動雙向閥的維護和保養的重要性。下面我們就來為大家詳細解說這三種閥門的拆卸步驟。

1.電動蝶閥的拆卸步驟

電動蝶閥具有結構緊湊、操作方便、密封性能優越等特點,廣泛應用於商業建築、公共建築、城市管道的給水或通風系統。拆卸時,請依照下列步驟操作:

(1)斷電排氣:先確保閥門斷電,關閉上、下游閥門,釋放管路內的壓力及殘餘介質。

(2)拆卸執行機構:用工具鬆開執行機構與閥體之間的連接螺栓,小心地將執行機構與閥體分離。

(3)拆卸閥桿、蝶板:用專用工具輕輕旋轉閥桿螺母,將閥桿、蝶板組件從閥體中抽出。

(4)檢查與清理:仔細檢查閥座、蝶板、密封圈的磨損狀況,必要時更換。同時清潔閥體內壁及各零件,確保無雜質殘留。

2、電動球閥的拆卸步驟

電動球閥因其高精度的流量控制和持久的密封性能在 HVAC 水系統中發揮重要作用。拆卸時,請依照下列步驟操作:

(1)斷電隔離:同樣確保閥門斷電,關閉上下游閥門,排空管路。

(2)拆除法蘭或螺紋連接:依照閥門的連接方式(法蘭或螺紋),使用對應的工具,鬆開連接件,將閥門與管路系統脫離開來。

(3)拆卸閥芯:輕輕旋轉閥桿,將閥芯從閥體上拆下,注意保護閥座和密封圈不受損壞。

(4)維護檢查:檢查閥芯、閥座、密封圈的磨損情況,必要時更換或修復。清潔所有組件,確保沒有雜質。

3.電動二通閥拆裝步驟

電動二通閥因具有彈簧復位、手動過載控制、接線方便等特點,廣泛應用於中央空調、供熱系統的溫度控制。拆卸時,請依照下列步驟操作:

(1)斷電及準備:確保閥門斷電,關閉上下游閥門,釋放管路壓力。

(2)拆卸執行器:用螺絲起子或其他工具小心拆開執行器外殼,露出內部的傳動機構。

(3)分離氣門桿與閥體:輕輕旋轉氣門桿螺母,將氣門桿和閥芯組件從閥體上拆下。

(4)檢查維修:檢查閥芯、閥座、密封圈的磨損狀況,必要時更換。清潔所有組件以確保沒有殘留異物。

(5)恢復與測試:以拆卸的相反順序重新組裝閥門,並進行功能測試,確保閥門運作正常。

Delcofluid閥門廠商提醒您,在進行任何拆卸工作之前一定要充分了解閥門的結構特點和拆卸步驟,並採取相應的安全措施,防止發生事故。同時,定期對閥門進行維護和保養可以大大延長其使用壽命,提高系統整體的運作效率。

如何快速獲得工業閥門的報價?

如果您對閥門有疑問或想獲得報價,請隨時聯絡我們,我們將在 6 小時內回覆。電話 +86 159 8960 2972、WhatsApp +86 159 8960 2972 或電子郵件行銷 [email protected]。

DELCO 的品質、有競爭力的價格和卓越的服務使其成為幫助您拓展業務的最佳閥門合作夥伴。定制您的閥門,我們沒有最低訂單量。

在 DELCO,我們了解客戶滿意度的重要性,並努力滿足每位客戶的獨特需求。作為可靠的控制閥供應商,我們致力於提供優質的客戶服務和高品質的產品,以確保最佳性能和使用壽命。選擇 DELCO 作為您值得信賴的控制閥供應商,您可以受益於專門設計用於滿足您的要求的客製化閥門組件,從而提高效率並減少停機時間。

此外,我們在電子壓力調節器方面的競爭性定價使您能夠提供一流的解決方案。作為領先的控制閥製造商之一,我們很自豪地提供可靠的閥門,這些閥門不僅符合行業標準,而且還能為您企業的整體盈利能力做出貢獻。透過與 DELCO 合作,您可以放心,因為您為公司的長期成功做出了明智的選擇。