Tech Theory: Technical…Practical… Interesting Automation Industrial Solutions

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control air supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

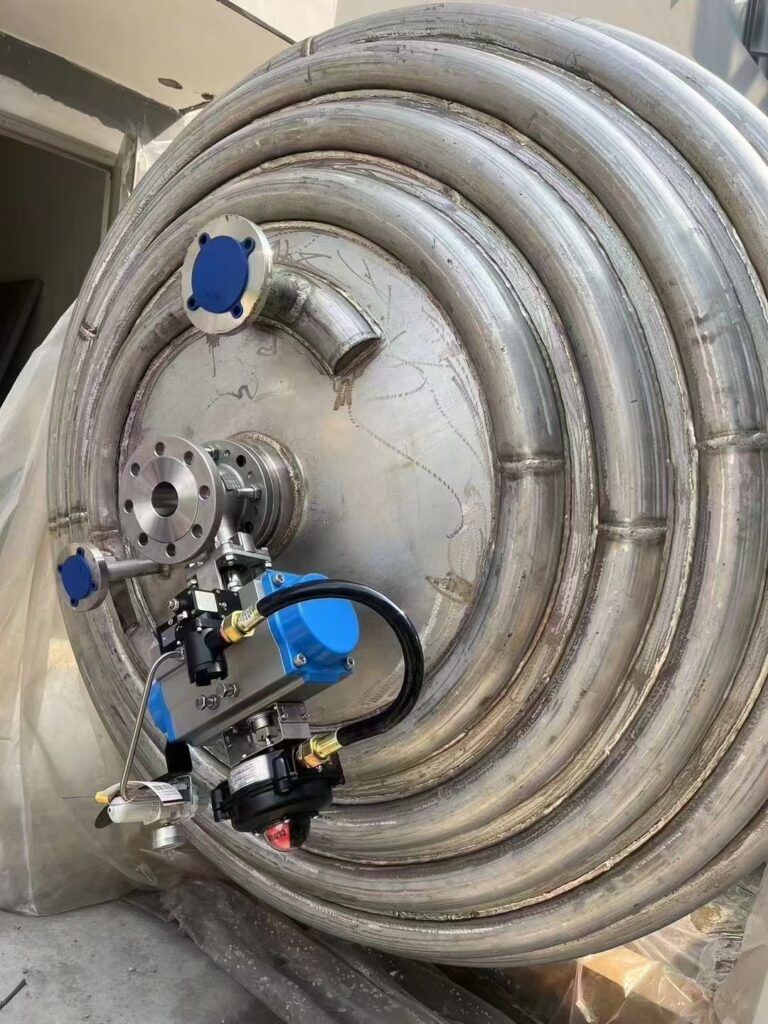

Why Choose a Bottom Ball Valve?

Introduction

In modern industry, reaction vessels are critical components in chemical, pharmaceutical, biotechnology, and food production processes. Optimizing these vessels’ discharge systems to ensure efficient material removal and cleanliness is crucial for improving production efficiency and ensuring product quality. The bottom ball valve, with its exceptional performance and innovative design, has become a key element in various clean industries. This article explores the applications and design features of the bottom ball valve to provide a comprehensive understanding of why it is highly favored in the industry.

Table of contents

Applications of Bottom Ball Valves

Bottom ball valves are widely used in clean industries such as pharmaceuticals, biotechnology, fine chemicals, and food processing. These industries have stringent requirements for equipment cleanliness, material discharge efficiency, and sealing performance. Here’s how bottom ball valves meet these needs in different fields:

1. Pharmaceutical Industry

In the pharmaceutical industry, bottom ball valves enhance production safety and efficiency. The valves’ design ensures no material residue, which prevents cross-contamination, and maintains the purity of pharmaceuticals. Their excellent sealing performance meets the stringent cleanliness standards required for drug production processes, ensuring high-quality and safe pharmaceutical products.

2. Biotechnology

The biotechnology sector involves various biological reactions and cultivation processes, requiring high standards of hygiene and ease of operation. Bottom ball valves are ideal for use in bioreactors due to their low residue design and easy maintenance. The valves ensure complete material discharge and simplify cleaning, thereby improving production efficiency and ensuring the quality and safety of bioproducts.

3. Fine Chemicals

In the fine chemicals industry, where high-value chemicals and complex reactions are common, bottom ball valves excel. Their full-bore design minimizes material retention inside the valve, reducing material loss and cross-contamination. This design also facilitates easy cleaning and maintenance, minimizing downtime and enhancing overall production efficiency.

4. Food Processing

Food processing demands exceptional cleanliness and hygiene standards. Bottom ball valves meet these needs with their no-residue and leak-proof features. They ensure hygienic material discharge and comply with strict food safety standards, enhancing the quality and safety of food products.

Design Features of Bottom Ball Valves

Bottom ball valves come with several unique design features that make them stand out in various applications. Here’s a detailed look at these design aspects:

1. Low Residue Area

The low residue area design ensures that materials are completely discharged with minimal residue. This feature is crucial in industries requiring high cleanliness, such as pharmaceuticals and food processing, and simplifies valve cleaning and maintenance, reducing contamination risks.

2. Direct Flow Path

The direct flow path design reduces material flow resistance within the valve, improving discharge efficiency. This design ensures smooth material flow, whether dealing with liquids or granular substances, and minimizes friction and loss during production.

3. Full-Bore Design

The full-bore design maintains the valve’s internal diameter consistent with the pipeline, avoiding pressure loss and flow reduction. This design improves fluid flow rates and efficiency while reducing energy consumption, making it ideal for applications requiring high flow rates.

4. Central Flange Structure

The central flange structure facilitates easy valve disassembly and maintenance. This design allows for quick replacement or repair of sealing components, lowering maintenance costs and time, and enhancing valve longevity.

5. Angled Valve Stem Design

The innovative angled valve stem design minimizes interference between the actuator and the reactor vessel. This design reduces installation space requirements and simplifies maintenance and repair, offering more flexible equipment layout options.

6. Compact Structure

The compact, integrated design enhances the valve’s stability and reliability. It reduces space usage, making it suitable for environments with limited space, and improves durability and long-term performance.

7. ISO5211 Direct Mount Platform

The ISO5211 direct mount platform standard allows the valve to connect directly with various actuators without additional adapters. This design simplifies installation, enhances system compatibility, and shortens integration time.

8. Packing Pressure Plate Structure

The packing pressure plate structure ensures reliable sealing of the valve’s packing. This feature maintains effective sealing during operation, reducing leakage risks and simplifying packing maintenance and replacement.

Conclusion

The bottom ball valve, with its no-residue discharge design, direct flow path, and full-bore structure, excels in the pharmaceutical, biotechnology, fine chemicals, and food processing industries. Its innovative features enhance material discharge efficiency, simplify maintenance, and provide excellent operational convenience. Choosing a bottom ball valve means improved production efficiency, lower maintenance costs, and superior performance, making it a valuable asset for industrial applications.

Founded in 2011, DELCO is a global leader in the industrial sector. Our main products include electric actuator valves, pneumatic actuator valves, automation actuators and solenoid valves. For nearly 20 years, we have utilized our products, engineering expertise and industrial automation solutions to solve countless industrial project problems for our customers, including food, beverage, chemical, water treatment, pharmaceutical, natural gas, oil and HVAC projects. We currently have five subsidiaries and more than 50 distributors around the world providing rapid response service.

All DELCO products undergo a 100% in-house design, engineering and manufacturing process led by highly skilled and experienced engineers using Italian and German technology to manufacture high quality, safe, reliable and value for money valves, actuators and solutions. Manufacturing standards can be demonstrated by the certifications obtained over the years.

And with the ISO 9001:2015 Quality Management System certification as well as many other certifications such as: SGS, RoHS, CNEX, TUV, CE, FDA. these certifications prove that DELCO adheres to the highest quality and safety standards worldwide when manufacturing its products.

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email marketing sales@delcofluid.com.

DELCO’s quality, competitive prices and excellent service make it the best valve partner to help you grow your business. Customize your valves, we have no minimum order.

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.