Tech Theory: Technical…Practical… Interesting Automation Industrial Solutions

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control air supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

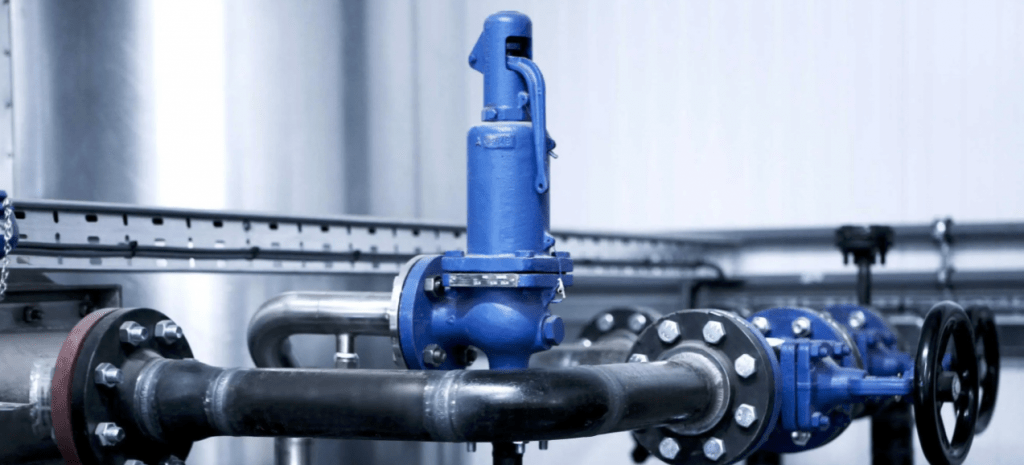

Safety valve is a special kind of valve. The opening and closing parts of the safety valve are normally closed under the action of external forces, and when the medium pressure in the equipment or pipeline rises above a specified value, the medium is discharged out of the system to prevent the medium pressure in the pipeline or equipment from exceeding the specified value. Safety valves not only play the role of the switch, but more importantly, to protect the safety of the equipment.

Role of the safety valve

Safety valve is an important safety accessory on the boiler, pressure vessel and other pressurized equipment. Safety valve (also known as pressure relief valve) is based on the working pressure or working temperature of the pressure system automatically open and close, generally installed in the closed system of equipment or pipeline to protect the system safety. When the pressure or temperature in the equipment or pipeline exceeds the set pressure of the safety valve, it automatically opens to relieve pressure or reduce temperature to ensure that the pressure (temperature) of the medium in the equipment and pipeline below the set pressure (temperature), to protect the normal operation of the equipment and pipeline to prevent accidents and reduce losses. Safety valves are widely used in: steam boilers, LPG car tankers, oil extraction wells, high-pressure bypass of steam generating equipment, pressure piping, pressure vessels and so on.

How to choose the right safety valve

- Consider the process conditions of the equipment as well as the working medium, characteristics. General boiler, pressure vessel discharge is not a small amount of the case of spring-loaded safety valves, otherwise the choice of full-opening safety valves is better.

- If the medium is toxic, flammable and explosive, closed safety valve should be selected.

- Each safety valve has its own working pressure range, selection should be in accordance with the actual demand for selection.

- Selected safety valve discharge must be greater than the amount of equipment discharge, so as to ensure that part of the medium is excluded, to avoid the pressure continues to rise.

Safety valve installation precautions

- All kinds of safety valves should be installed vertically.

- Safety valve outlet should be free of resistance, to avoid the phenomenon of pressure.

- Safety valves should be specially tested and their sealing checked before installation.

- Safety valves in use should be inspected regularly.

Common faults and solutions of safety valves

- Valve flap and seat sealing surface at the occurrence of more than the permissible degree of leakage: leakage is due to the valve flap and seat sealing surface between the dirt, you can open the valve a few times for flushing; if the sealing surface damage, according to the degree of damage can be used to repair the method of grinding or turning and then grinding; if it is the valve stem bending should be re-fitting or replacement.

- To the specified pressure does not open and to the specified pressure does not close: this is due to the safety valve positioning is not allowed to cause, should be readjusted spring compression or the position of the weight or replace the spring.

- The pressure continues to rise after the safety valve exhausts: this is mainly because the discharge of the safety valve does not reach the discharge of the equipment, and a suitable safety valve should be selected.

- Valve flap frequency jump or vibration: This is mainly because the spring stiffness is too large, should be changed to the appropriate stiffness of the spring.

- Safety valve does not return to the seat after discharge: this is mainly caused by the spring bending, valve stem, valve flap installation position is not correct or stuck, should be reassembled.

Choose safety valves from DELCO Valve

DELCO Valve is a top brand specializing in high-quality valve solutions. Our main products include a wide range of control valves,motorized valves, pneumatic valves, solenoid valves, manual valves, actuator and valve fittings. We are dedicated to offering customers reliable and efficient valve products for various industrial and commercial uses.

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email marketing [email protected].

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.