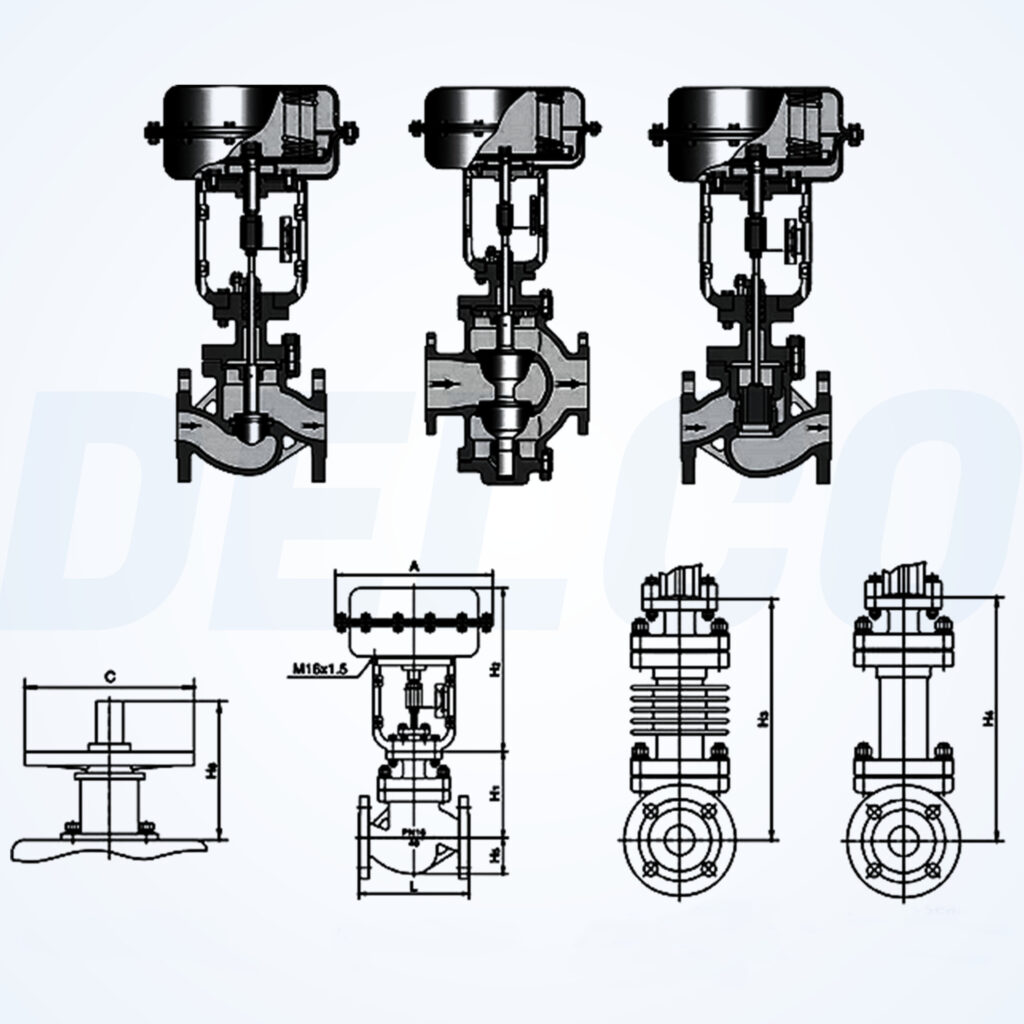

DELCO Pneumatic Control Valves-ZJHP/ZJHM

Pneumatic control valves are essential components in industrial automation, regulating fluid flow using pneumatic actuators.

The main advantages of the pneumatic control valve are that the opening and closing speed of the pneumatic control valve is easy to adjust, the structure is simple, and it is easy to maintain. Due to the buffer characteristics of the gas itself during the operation, it is not easy to be damaged due to jamming. It is more reliable than the electric valve in some explosion-proof situations

Model: Pneumatic Control Valve

Size Range: 1/2”~12′

Pressure Range: 1.6~6.4Mpa

Material: Stainless Steel 304, 316, 316L or WCB

Description

Pneumatic Control Valves is a type of valve that utilizes the principles of pneumatics to regulate the flow of fluids. This valve is typically controlled by a pneumatic actuator, which is powered by compressed air or other gases. Pneumatic control valves find widespread application in industrial automation systems, where they are employed to adjust parameters such as pressure, flow, and temperature of fluid media to meet process requirements.

The operational principle involves altering the valve’s opening by adjusting the position of the pneumatic actuator. This type of valve is known for its rapid response, precise control, and reliable performance, making it suitable for various industrial sectors, including chemical, petroleum, pharmaceuticals, and manufacturing industries.

Pneumatic control Valves Technical Parameters:

| Type | Nominal pressure | Structure | Cooling type | Packing |

| Single-seat, double seat, sleeve | PN16, PN25, PN40, PN63 | Standard type (-20℃ ~+200℃ ) |

(-40~450℃ ) | V type PTFE, flexible graphite |

| Nominal diameter | Connection | Material | Low-temperature type | Adjustable range |

| DN15-DN300 | Flange, thread, weld (Or other customer specified) |

Stainless Steel or WCB | (-60℃ ~-196℃ ) | 50:1 |

| Sealing surface | Basic error | Accessories | Leakage class | |

| PN16 convex surface, PN40, PN63 | Less than full stroke +-1% (With locator) Less than full | locator, air filter pressure-relief valve, hand wheel device, limit switch, solenoid valve, lock up valve, and others. | Metal seal: Less than 0.01 (ANSI B16.104-1976IV) | Soft seal: Less than 0.00001% |

Valve components: Single-seat plunger core type, 304, 316+ SLT core seat with equal percentage,linear, quick-opening low characteristics.

Valve Actuator: Multi-spring diaphragm actuator in direct action & reverse action. NBR rubberreinforcing polyester fabric diaphragm material. Spring range 20~100KPa,40~200KPa,80-240KPa.Supply pressure from 0.4MPa to 0.5MPa

Action type: Air to close FO (with direct action actuator), when the air supply failure, actuator springopen the valve; Air to open FC (With reverse action actuator) When the air supply failure, actuator springcloses the valve. Linear,equal percentage, quick opening.

Choosing the Right Control Valves

When selecting a control valve, consider the following factors:

Flow requirements: Evaluate the flow characteristics needed for the specific application.

Flow Characteristics: Consider the fluid’s properties, such as viscosity, pressure, and temperature, to select a valve that can handle the specific conditions.

Valve size: Choose a valve size that matches the pipeline size and meets the required flow capacity.

Actuator type: Decide between manual, electric, pneumatic, or hydraulic actuation based on the system requirements and available resources. Select an actuator that provides adequate force and meets the desired control requirements.

Material compatibility: Ensure the valve materials are compatible with the fluid being handled to avoid corrosion or other damage.

Regulatory requirements: Adhere to industry-specific regulations and standards to ensure safe and efficient operation.

Noise and vibration: Option for a valve design that minimizes noise and vibration for a safer, more reliable operation.

One-time business is not our goal, we pursuit for long-term partner relationships.

We are not just providing simple quotes but experts in selection, calculation, and drawing.

ASK FOR A QUOTE

Related products

Offering Industry-Oriented Valve Solution For You

The company not only controls the quality in real time, but also zero tolerance for problems is the pursuit of high quality. Workers must undergo rigorous training and strict assessment before they can take up their jobs.

Quality Assurance

Calculation & Selection, Quality Control, Inspection, After-Sales Service, etc. Each Production Loop to Ensure Our Customers Have No Worries.

Services

At DELCO, we believe there always has a better valve solution for every single customer. We’re obsessively passionate about it, and our mission is to manufactures & supply a range of innovative control valves & pressure regulators backed by global service support, thereby guaranteeing zero defects within the shortest lead time.

Production Market

DELCO Has A Wide Reach, Exporting To Over 46 Nations. So We Have A Complete Picture Of The Market. Welcome To Become A Long-Term Business Partner With Us. Reliable Control Valves and Self-Operated Pressure RegulatorsManufacturer

Company Honor

DELCO valve has CE, RoHS, FDA, Explosion-proof electrical apparatus.

For over 20 years, DELCO Valves has been committed to providing our customers with high quality valves.

DELCO has always been centered around one thing: 100% customer satisfaction. We strive for continuous improvement in all aspects of our daily operations. Our mission, coupled with a product line that is manufactured to the highest quality standards, continues to be what sets us apart from our competition. At Powell, all of our facilities are ISO 9001 “Global Quality” certified.

As a leading manufacturer of industrial valves, we offer a wide range of products. Our product lines include: gate valves, check valves, globe valves, check valves, double plate check valves and high performance butterfly valves. With the most complete multi-turn product line from a single-source manufacturer, our valves are manufactured to the highest quality standards using ultra-modern manufacturing techniques and astute material sourcing.

As a full-service valve company, we offer a wide range of products as well as retrofit and field services. Our valve expertise is unrivaled and we look forward to meeting your future valve needs!