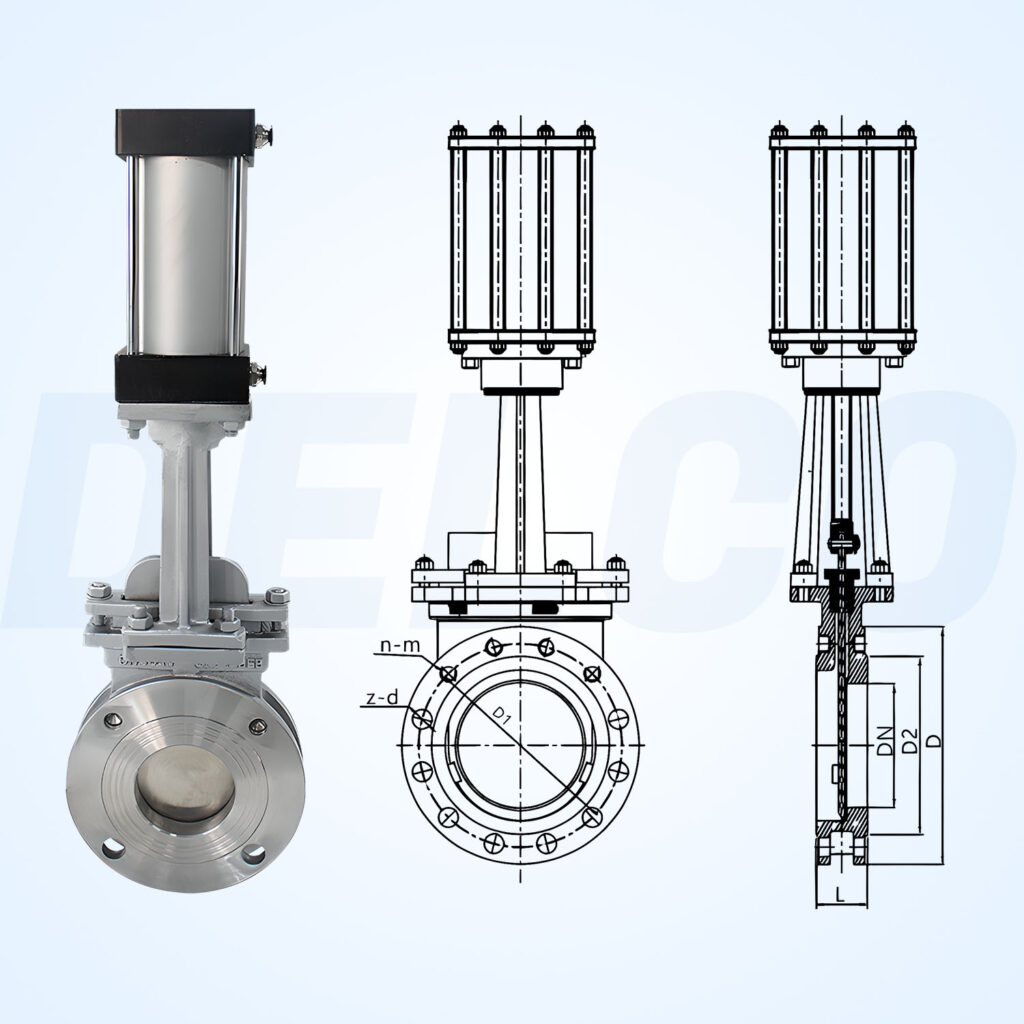

DELCO Pneumatic Actuator Knife Gate Valve

The Knife Gate Valve is a unidirectional wafer knife edge gate valve used on industrial pipeline for on-off operation.

The structure of body and seat eliminates clogging shutoff for flow with fine particles. Additionally, beveled knife edge helps the gate cut through thick media easily.

Pneumatic Actuator knife gate valves represent a critical evolution in the technology and application of industrial valves. They are specifically designed to control the flow of abrasive, viscous, or solid-laden fluids, making them indispensable in sectors like mining, wastewater treatment, pulp and paper, and bulk handling. This detailed exploration delves into the design, operation, advantages, and applications of pneumatic knife gate valves, highlighting their significance in modern industrial operations.

Model: Pneumatic Actuator Knife Gate Valve

Size Range: 2”~24”

Pressure Range: 0.0MPa to 1.0MPa

Material: Cast Iron, Stainless Steel 304 or 316

Description

A pneumatic knife gate valve consists of a slender gate that slices through media, operated by a pneumatic actuator. The design is straightforward yet effective, featuring a sharp-edged gate that can cut through heavy slurries, paste-like substances, and even solid materials that are part of the flowing medium. This capability to handle challenging flow materials without clogging or jamming sets it apart from other valve types.

The pneumatic actuator, which can be double-acting (air to open, air to close) or single-acting with a spring return, provides the motive force. The use of compressed air as the actuation medium offers rapid action and a high degree of control over the valve’s opening and closing, enhancing process efficiency and safety. The valve body can be made from various materials, including stainless steel, cast iron, or specialized alloys, to suit different media and application environments.

The operation of a pneumatic knife gate valve is governed by the delivery of compressed air to the pneumatic actuator. When air is introduced into the actuator, it creates a force that moves the piston, which in turn slides the gate up or down. This motion allows for the precise control of flow, from fully open to fully closed positions, and any intermediate level as required by the process. The rapid actuation is particularly beneficial for applications where quick isolation or restoration of flow is necessary.

Technical Parameters

| Double acting | Single acting N/C | Single acting N/O | Optional accessory | ||

| Air to open, air to close, air supplier failure to keep the current position | Air to open, interrupt air to close, air failure to close | Air to close, interrupt air to open, air failure to open | Reversing solenoid valve, limit switch box, air filter reducing valve, positioner, handle manual, lock up valve. | ||

| Body | Size range | Body material | End connection | Operating pressure | Structure |

| DN50~DN600 | Cast iron | Flange | 0.0MPa to1MPa |

Midline Structure | |

| Valve components |

Sealing material | Core material | Stem material | Applicable media | |

| PTFE, PPL | Stainless steel | Stainless steel | Water, oil, Gas, Liquid, steam, powder, anti-corrosive base | ||

Pneumatic Actuator Knife Gate Valve

Features

Body:

An integral body with full bore structure ensures smooth flow, easy assembly, and smaller shell leakage possibility.

Guide claws designed at the port bottom for gate fixture, instead of a groove, eliminate any potential clogging when valve shutoff.

Gate:

The beveled knife edge provides strong cutting stress and tight sealing.

PTFE resilient point guide above the port prevents metal-metal contact between the gate and body.

Gate thickness can be increased to meet higher pressure.

Seat:

The seat can be replaceable, reducing the maintenance cost, and can be adjustable to meet different sealing classes and compensate for normal seat wear.

Advantages

Versatility: Pneumatic knife gate valves can handle a wide variety of media, including corrosive, abrasive, and viscous fluids, as well as dry bulk materials.

Durability: Designed to withstand harsh conditions, these valves can operate efficiently in environments with high concentrations of solids or abrasive materials.

Low Maintenance: The simple design and robust construction minimize maintenance requirements and prolong service life.

Rapid Response: The pneumatic actuation ensures quick and reliable valve operation, critical in emergency shutoff scenarios and automated processes.

Cost-Effective: Despite their advanced functionality, pneumatic knife gate valves are cost-effective, offering a lower total cost of ownership compared to other valve types suitable for similar applications.

One-time business is not our goal, we pursuit for long-term partner relationships.

We are not just providing simple quotes but experts in selection, calculation, and drawing.

ASK FOR A QUOTE

Related products

Offering Industry-Oriented Valve Solution For You

The company not only controls the quality in real time, but also zero tolerance for problems is the pursuit of high quality. Workers must undergo rigorous training and strict assessment before they can take up their jobs.

Quality Assurance

Calculation & Selection, Quality Control, Inspection, After-Sales Service, etc. Each Production Loop to Ensure Our Customers Have No Worries.

Services

At DELCO, we believe there always has a better valve solution for every single customer. We’re obsessively passionate about it, and our mission is to manufactures & supply a range of innovative control valves & pressure regulators backed by global service support, thereby guaranteeing zero defects within the shortest lead time.

Production Market

DELCO Has A Wide Reach, Exporting To Over 46 Nations. So We Have A Complete Picture Of The Market. Welcome To Become A Long-Term Business Partner With Us. Reliable Control Valves and Self-Operated Pressure RegulatorsManufacturer

Company Honor

DELCO valve has CE, RoHS, FDA, Explosion-proof electrical apparatus.

For over 20 years, DELCO Valves has been committed to providing our customers with high quality valves.

DELCO has always been centered around one thing: 100% customer satisfaction. We strive for continuous improvement in all aspects of our daily operations. Our mission, coupled with a product line that is manufactured to the highest quality standards, continues to be what sets us apart from our competition. At Powell, all of our facilities are ISO 9001 “Global Quality” certified.

As a leading manufacturer of industrial valves, we offer a wide range of products. Our product lines include: gate valves, check valves, globe valves, check valves, double plate check valves and high performance butterfly valves. With the most complete multi-turn product line from a single-source manufacturer, our valves are manufactured to the highest quality standards using ultra-modern manufacturing techniques and astute material sourcing.

As a full-service valve company, we offer a wide range of products as well as retrofit and field services. Our valve expertise is unrivaled and we look forward to meeting your future valve needs!