Manual Fluorine Lined Flange Ball Valve with Handle

The fluorine-lined ball valve boasts exceptional chemical stability and a compact, well-designed structure. With a full-bore, floating ball design, the valve minimizes internal cavity space, reducing medium retention and maximizing flow. This facilitates pipeline system pigging, cleaning, and maintenance. The specialized molding process ensures a dense and reliable sealing surface, further enhanced by the chevron-shaped PTFE packing, achieving zero leakage. The robust, high-strength blowout-proof stem limits lag phenomena, ensuring reliable operation.

The durable, corrosion-resistant PTFE valve seat is designed for zero leakage and low-torque isolation. Metal-to-metal body joints protect the locked liner from external damage, and the anti-static grounding device prevents static buildup. The manual fluorine-lined ball valve is suitable for transporting liquids and gases (including steam) in various industrial pipelines and performs well in highly corrosive media such as acids and salts.

Model: Fluorine Lined Flange Ball Valve

Size Range: 1/2″ to 16″

Pressure Range: PN1.6, 2.5, 4.0, 6.4 MPa

Material : Cast Steel

Features

- Compact design: The compact and efficient design minimizes medium retention within the valve body cavity.

- Durable Valve Seat: The durable, corrosion-resistant PTFE valve seat is designed for zero leakage and low-torque isolation.

- Excellent Corrosion Resistance: The valve maintains stable performance in highly corrosive media such as acids, alkalis, and salts.

- Floating Ball Structure: The valve features a floating ball structure that achieves zero leakage shutoff across the entire pressure range, facilitating pipeline cleaning and maintenance.

- Sealing Technology : A special molding process ensures a dense sealing surface. Combined with PTFE packing, the valve achieves zero leakage.

- Enhanced Durability: The compact and efficient design, combined with advanced sealing technology, reduces medium retention and enhances durability and reliability.

Technical Parameters

| Port Size: | 1/2″ to 16″ | Material: | Cast Iron, Cast Steel, WCB or Stainless Steel |

| Pressure: | 1.6 to 6.4MPa | End Connection: | Flange |

| Warranty: | 12 Moths | Working Temperature: | PTFE≤180°C, Metal Seated≤350°C |

| Pressure Rating: | 300LB ( 150LB and 600LB is optional) | Suitable Media | Air, Inert Gas, Oil, Seawater, Water, and other media. |

Application

1. Chemical Industry

In the chemical industry, these valves are used to handle corrosive chemicals and ensure the reliability of pipeline operations. They play a critical role in the transportation, mixing, and reaction of chemicals, and are designed to resist harsh environments including acids, alkalis, and salts.

2. Pharmaceutical Industry

In the pharmaceutical industry, these valves are ideal for applications requiring high purity and reliable isolation. They are used in the drug production process to ensure sterility, purity, and precise control of conditions to prevent contamination.

3. Food Processing Industry

In the food processing industry, manual fluorine-lined flanged ball valves are employed for handling food and beverage products. They are suitable for environments that demand hygienic conditions and resistance to aggressive cleaning agents.

4. Environmental Protection Industry

In the environmental protection industry, these valves are used for wastewater management, pollutant treatment, and ensuring compliance with environmental regulations. They are essential for effective pollution control and environmental protection efforts.

One-time business is not our goal, we pursuit for long-term partner relationships.

We are not just providing simple quotes but experts in selection, calculation, and drawing.

ASK FOR A QUOTE

Related products

Offering Industry-Oriented Valve Solution For You

The company not only controls the quality in real time, but also zero tolerance for problems is the pursuit of high quality. Workers must undergo rigorous training and strict assessment before they can take up their jobs.

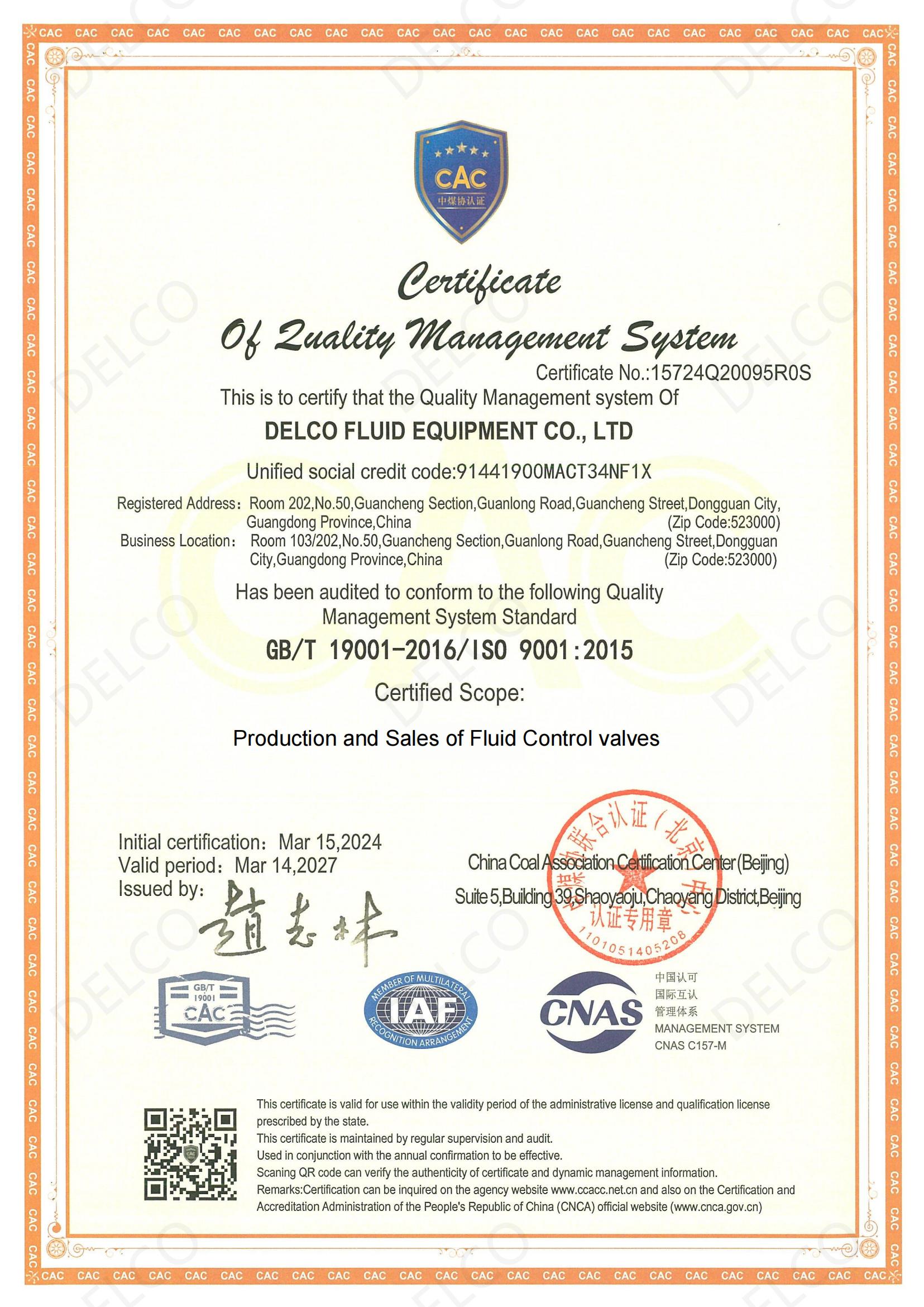

Quality Assurance

Calculation & Selection, Quality Control, Inspection, After-Sales Service, etc. Each Production Loop to Ensure Our Customers Have No Worries.

Services

At DELCO, we believe there always has a better valve solution for every single customer. We’re obsessively passionate about it, and our mission is to manufactures & supply a range of innovative control valves & pressure regulators backed by global service support, thereby guaranteeing zero defects within the shortest lead time.

Production Market

DELCO Has A Wide Reach, Exporting To Over 46 Nations. So We Have A Complete Picture Of The Market. Welcome To Become A Long-Term Business Partner With Us. Reliable Control Valves and Self-Operated Pressure RegulatorsManufacturer

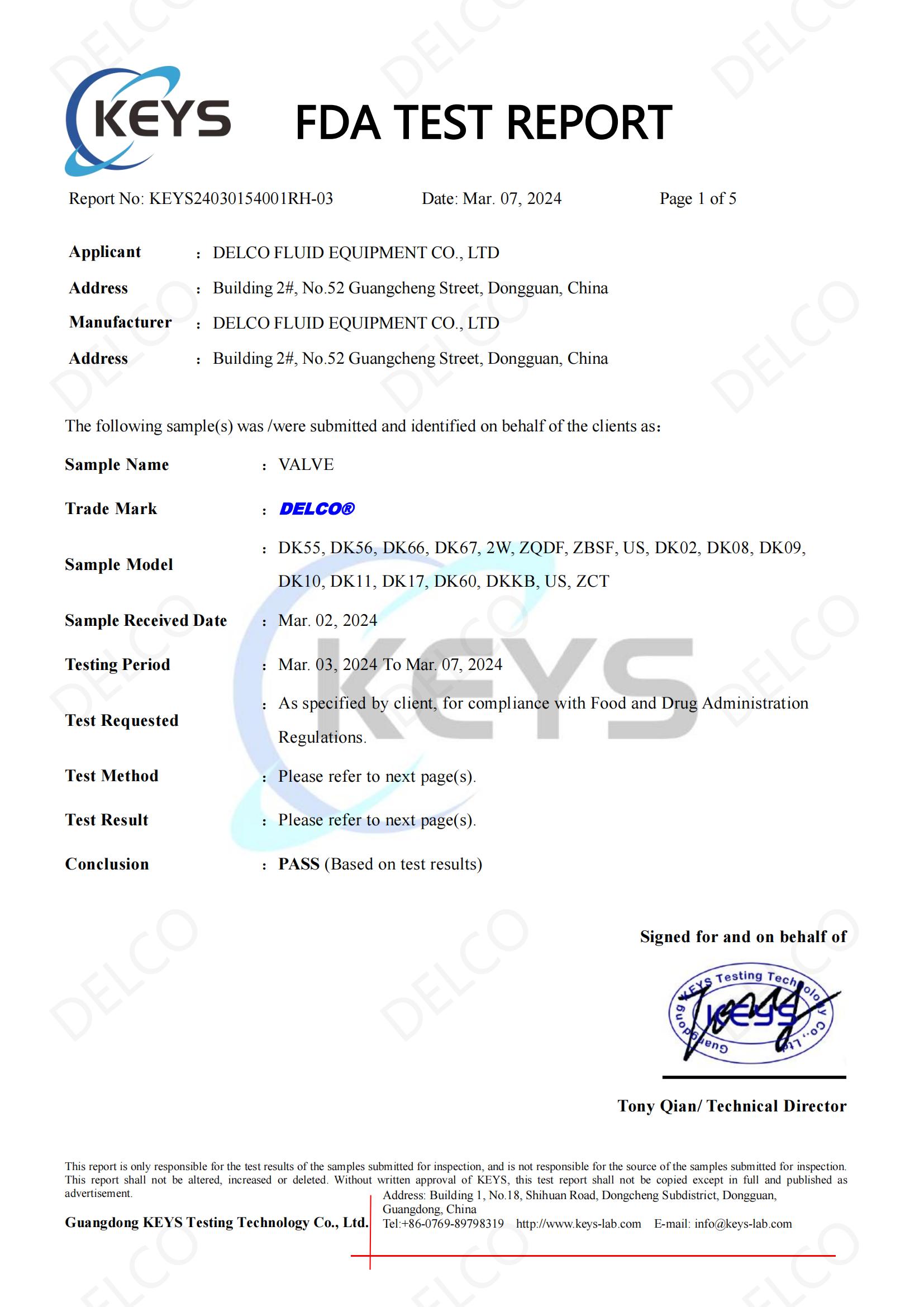

Company Honor

DELCO valve has CE, RoHS, FDA, Explosion-proof electrical apparatus.

For over 20 years, DELCO Valves has been committed to providing our customers with high quality valves.

DELCO has always been centered around one thing: 100% customer satisfaction. We strive for continuous improvement in all aspects of our daily operations. Our mission, coupled with a product line that is manufactured to the highest quality standards, continues to be what sets us apart from our competition. At Powell, all of our facilities are ISO 9001 “Global Quality” certified.

As a leading manufacturer of industrial valves, we offer a wide range of products. Our product lines include: gate valves, check valves, globe valves, check valves, double plate check valves and high performance butterfly valves. With the most complete multi-turn product line from a single-source manufacturer, our valves are manufactured to the highest quality standards using ultra-modern manufacturing techniques and astute material sourcing.

As a full-service valve company, we offer a wide range of products as well as retrofit and field services. Our valve expertise is unrivaled and we look forward to meeting your future valve needs!