DELCO ZCT High Pressure Stainless Steel Solenoid Valve

DELCO high-pressure solenoid valve works mainly on the electromagnetic force to control the movement of the spool, so as to realize the on-off control of the fluid. Its simple structure, high reliability, and fast response speed, suitable for rapid and accurate control of the fluid occasions.

Normally Closed: When the coil is powered, the pilot valve core attracts, opening the pilot hole. This releases pressure in the upper chamber, enabling the medium pressure in the lower chamber to push the piston, opening the solenoid valve. When the coil is turned off, the pilot valve core resets due to the spring, closing the pilot hole. The upper chamber pressurizes through the piston orifice and the reset spring’s force, closing the solenoid valve.

Normally Open: When the coil is powered, the pilot hole closes. The upper chamber pressurizes through the piston orifice and the reset spring’s force, closing the solenoid valve. When the coil is turned off, the pilot valve core resets due to the spring, opening the pilot hole. This releases pressure in the upper chamber, allowing the medium pressure in the lower chamber to push the piston, opening the solenoid valve.

- Model: High-Pressure Solenoid Valve

- Size Range:1/8″~1″

- Pressure Range: 0MPa~1.0MPa

- Material: Stainless Steel 304/316

High Pressure Solenoid Valves

High-pressure solenoid valve is a kind of solenoid valve that plays the role of pipeline control in high-pressure environment. It usually consists of coil, core, valve and sealing materials and other components, mainly by changing the size of the magnetic field generated within the solenoid coil to drive the valve switch, so as to achieve the medium input / output regulation.

High Pressure Solenoid Valves technical Parameter:

| Type | Solenoid valve | Port Size | 1/8″~1″ |

| Material | Stainless steel | Sealing Material | PTFE |

| Pressure | 0 MPa-1.0 MPa | Function | Normally closed |

| Warranty | 12 moths | Orifice(mm) | –5.0, 6.0, 7.0 |

| Function | Normally closed or opened | Model | ZCT |

High Pressure Solenoid Valves Applications:

- Hydraulic Systems: Commonly used in systems that move liquids under pressure, controlling parts like pumps, cylinders, and motors accurately.

- Pneumatic Systems: Used for controlling air-powered devices, making actions like extending cylinders or opening valves possible.

- Gas Systems: Manage gas flow and pressure for safety and stability in gas-operated systems.

- Other Uses: Found in water, heating, and air conditioning systems to precisely regulate water and air flow, improving system efficiency and performance.

High Pressure Solenoid Valves Benefits:

- Corrosion Resistance: Unlike normal valves that can rust or wear down over time, high-temperature and high-pressure solenoid valves resist corrosion. They also seal well to keep out water vapor.

- High-Temperature Durability: High-temperature and high-pressure solenoid valves can work for long periods up to 300°C.

- Long Lifespan: Typical high-pressure solenoid valves last only a few months and are expensive. However, special high-temperature and high-pressure solenoid valves, made with specific materials, can last over five times longer than standard products.

- Excellent Explosion Protection: Regular solenoid valves can potentially explode or catch fire during use. On the other hand, using high-temperature and high-pressure solenoid valves can effectively reduce these risks.

Conclusion:

In conclusion, directly operated high-pressure solenoid valves play a crucial role in ensuring efficient and reliable fluid control in demanding environments. With their advanced features, precise operation, and broad applicability, these valves are indispensable components across a range of industries. As technology continues to advance, these valves will remain at the forefront of fluid control solutions, driving innovation and enhancing performance in critical systems.

One-time business is not our goal, we pursuit for long-term partner relationships.

We are not just providing simple quotes but experts in selection, calculation, and drawing.

ASK FOR A QUOTE

Related products

Offering Industry-Oriented Valve Solution For You

The company not only controls the quality in real time, but also zero tolerance for problems is the pursuit of high quality. Workers must undergo rigorous training and strict assessment before they can take up their jobs.

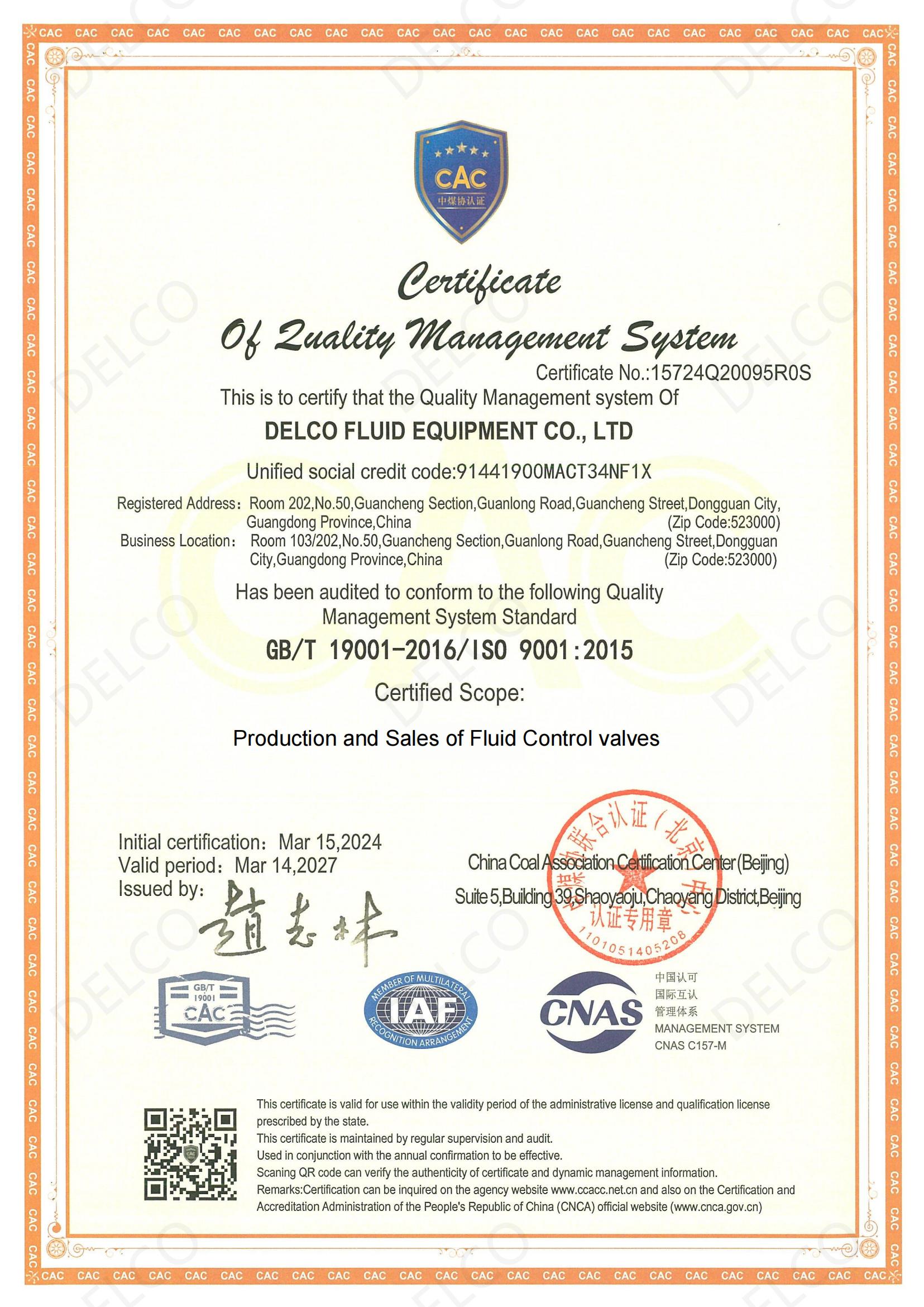

Quality Assurance

Calculation & Selection, Quality Control, Inspection, After-Sales Service, etc. Each Production Loop to Ensure Our Customers Have No Worries.

Services

At DELCO, we believe there always has a better valve solution for every single customer. We’re obsessively passionate about it, and our mission is to manufactures & supply a range of innovative control valves & pressure regulators backed by global service support, thereby guaranteeing zero defects within the shortest lead time.

Production Market

DELCO Has A Wide Reach, Exporting To Over 46 Nations. So We Have A Complete Picture Of The Market. Welcome To Become A Long-Term Business Partner With Us. Reliable Control Valves and Self-Operated Pressure RegulatorsManufacturer

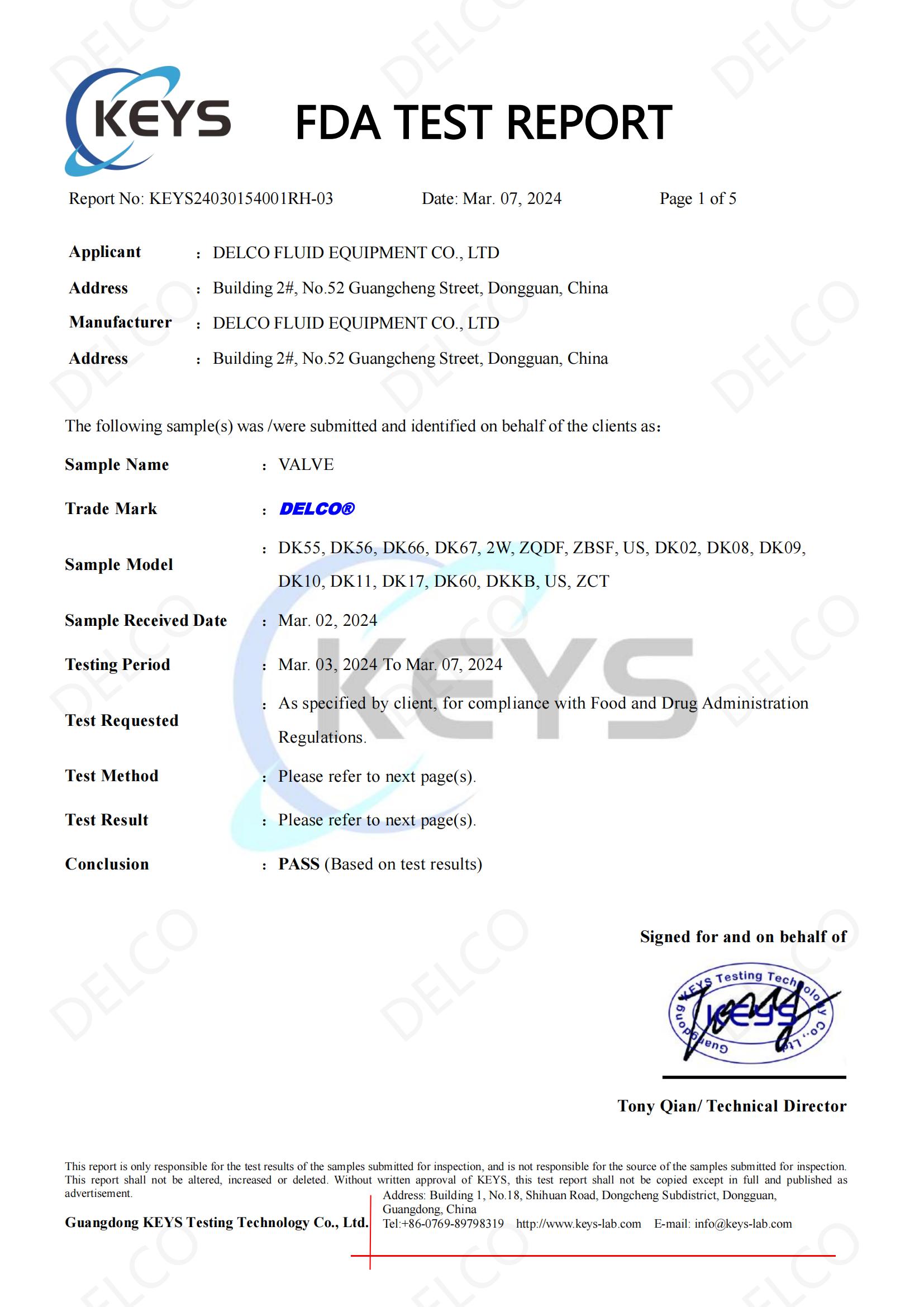

Company Honor

DELCO valve has CE, RoHS, FDA, Explosion-proof electrical apparatus.

For over 20 years, DELCO Valves has been committed to providing our customers with high quality valves.

DELCO has always been centered around one thing: 100% customer satisfaction. We strive for continuous improvement in all aspects of our daily operations. Our mission, coupled with a product line that is manufactured to the highest quality standards, continues to be what sets us apart from our competition. At Powell, all of our facilities are ISO 9001 “Global Quality” certified.

As a leading manufacturer of industrial valves, we offer a wide range of products. Our product lines include: gate valves, check valves, globe valves, check valves, double plate check valves and high performance butterfly valves. With the most complete multi-turn product line from a single-source manufacturer, our valves are manufactured to the highest quality standards using ultra-modern manufacturing techniques and astute material sourcing.

As a full-service valve company, we offer a wide range of products as well as retrofit and field services. Our valve expertise is unrivaled and we look forward to meeting your future valve needs!