DELCO Cast Iron Multi Turn Electric Actuator Gate Valves

The Z-type multi-turn Gate Valves electric actuator is a critical component utilized for operating, shutting, or adjusting valves. It serves as a pivotal actuating mechanism enabling remote, centralized, or self-control functionalities over valves. Renowned for its versatility, reliability, and advanced control system, this actuator boasts a compact design, lightweight construction, and ease of application and maintenance.

Designed to accommodate valves with linear motion mechanisms, such as gate valves, stop valves, diaphragm valves, anchor gates, and water gate valves, the Z-type actuator offers comprehensive functionality. Its reliable performance and advanced control capabilities make it indispensable across various industries where precise valve control is paramount for operational efficiency and safety.

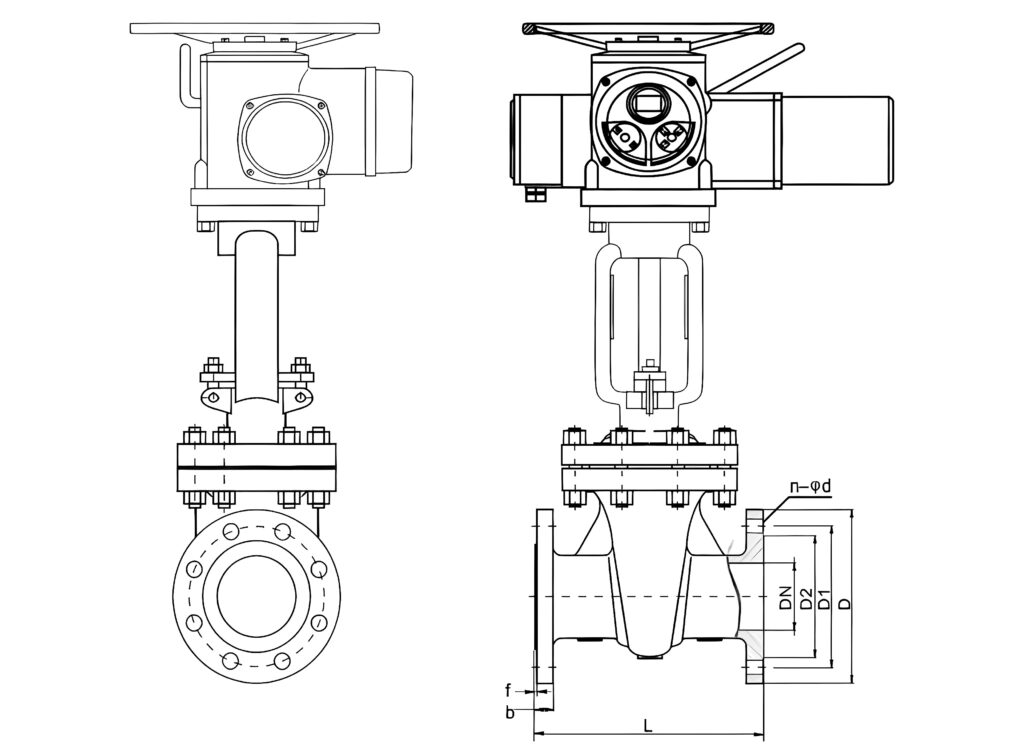

Model: Electric Actuator Gate Valves

Size Range: 2” to 40”

Pressure Range: 1.6MPa-6.4MPa

Material: Cast Iron, Stainless Steel 304/316

What Is Multi-turn Electric Gate Valve?

Multi-turn electric gate valves are sophisticated control valves engineered for precise and automated flow regulation in a wide range of industrial settings. Unlike manual gate valves that require manual operation to open or close, multi-turn electric gate valves are equipped with an electric actuator that rotates the valve stem to precisely position the gate within the valve body. This electric actuation enables remote operation and automation, allowing for seamless integration into control systems for efficient flow control.

These valves are designed to control the flow of fluids by raising or lowering a gate or wedge mechanism within the valve body. The multi-turn electric actuator facilitates precise positioning of the gate, enabling accurate and repeatable control over fluid flow rates. Multi-turn electric gate valves find applications in industries such as oil and gas, water treatment, power generation, and chemical processing, where reliable and automated flow control is essential for operational efficiency and safety.

Technical Parameters of Valve Actuator

| Power supply | general: single-phase 220v, three-phase 380v(50Hz), long distance DC24V |

| special: single-phase 110v, three-phase 415v, 660v(50Hz, 60Hz) | |

| Working environment | Ambient temperature: -20 ~ + 60 ℃ (special temperature environment can be customized) |

| Relative humidity: 95% (at 25 ° C) | |

| The outdoor type can be used in the places without inflammable / explosive and corrosive medium | |

| d I | applicable to non-excavating workinarea for coal mine |

| d I BT4 | applicable to the environment with IIA , IIB grade TL-T4explosive gas mixture , can be used in the factory |

| Protection level | Outdoor type and explosion-proof type are IP55 (IP65, IP67) |

| Working time | short time 10 minutes (15-60 minutes for special order) |

SS316 Motorized Actuator Flange Globe Valve

- Applicable industries: electric power, metallurgy, petroleum, chemical engineering, paper-making, sewage disposal and so on.

- There are many types for multi-turn electric actuator:

- outdoor type, explosion-proof type, integral typeintegral-regulation type, integral explosion-proof type, integral-regulation explosion-proof type and so on.

- It can be divided into torque type and thrust type according to the connection type.

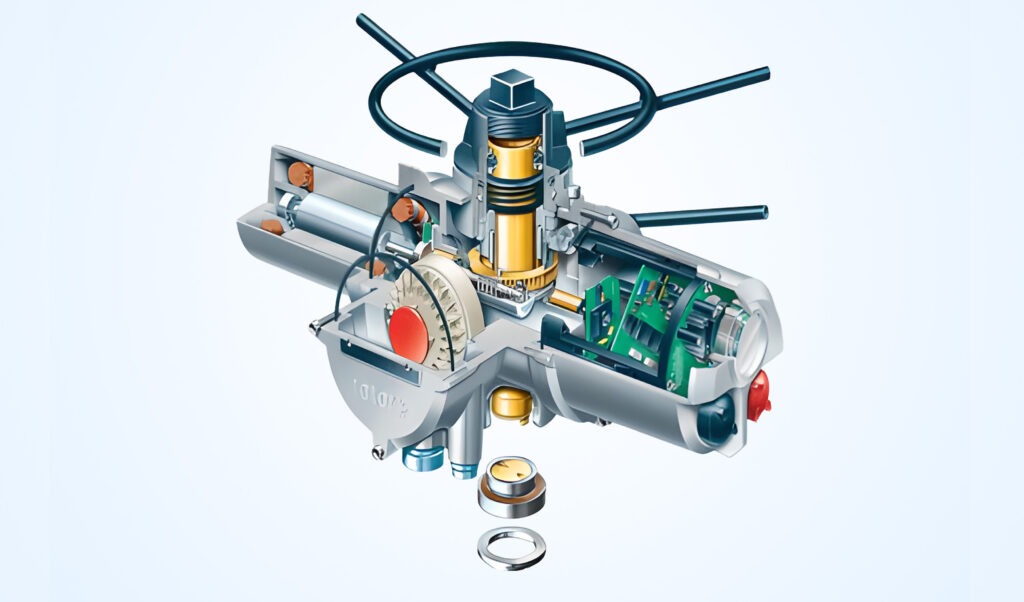

Electric Actuator:

ON/OFF Type Electric Actuator: Featuring a 90-degree rotation, this actuator offers AC/DC power supply, signal control, and manual override capabilities. With high torque of up to 4000Nm, it ensures reliable performance in demanding environments.

Modulating Type Electric Actuator: Adjust the open/close angle smoothly from 0 to 90 degrees with this actuator. Equipped with AC/DC power supply, signal control, and manual override, it delivers precise control and high torque of up to 4000Nm.

Intelligent Type Electric Actuator: Take control with ease using the intelligent actuator, allowing you to adjust the open/close angle with precision. Featuring an LED display screen for convenient monitoring, it offers AC/DC power supply, signal control, manual override, and high torque of up to 4000Nm.”

| Valve Body | Valve components | ||

| Nominal size | DN50-DN1000 | Sealing material | PTFE, EPDM |

| Body Material | Cast Iron /Stainless Steel | Disc Material | Stainless Steel |

| End Connection | Flange Ends & Butt welding Ends | Stem Material | Carbon iron |

| Operating Pressure | ASME CL, 150, 300, 600, 900, 1500, 2500 | Applicable media | Water, Air, Gas, Petroleum, Oil, Liquid |

One-time business is not our goal, we pursuit for long-term partner relationships.

We are not just providing simple quotes but experts in selection, calculation, and drawing.

ASK FOR A QUOTE

Related products

Offering Industry-Oriented Valve Solution For You

The company not only controls the quality in real time, but also zero tolerance for problems is the pursuit of high quality. Workers must undergo rigorous training and strict assessment before they can take up their jobs.

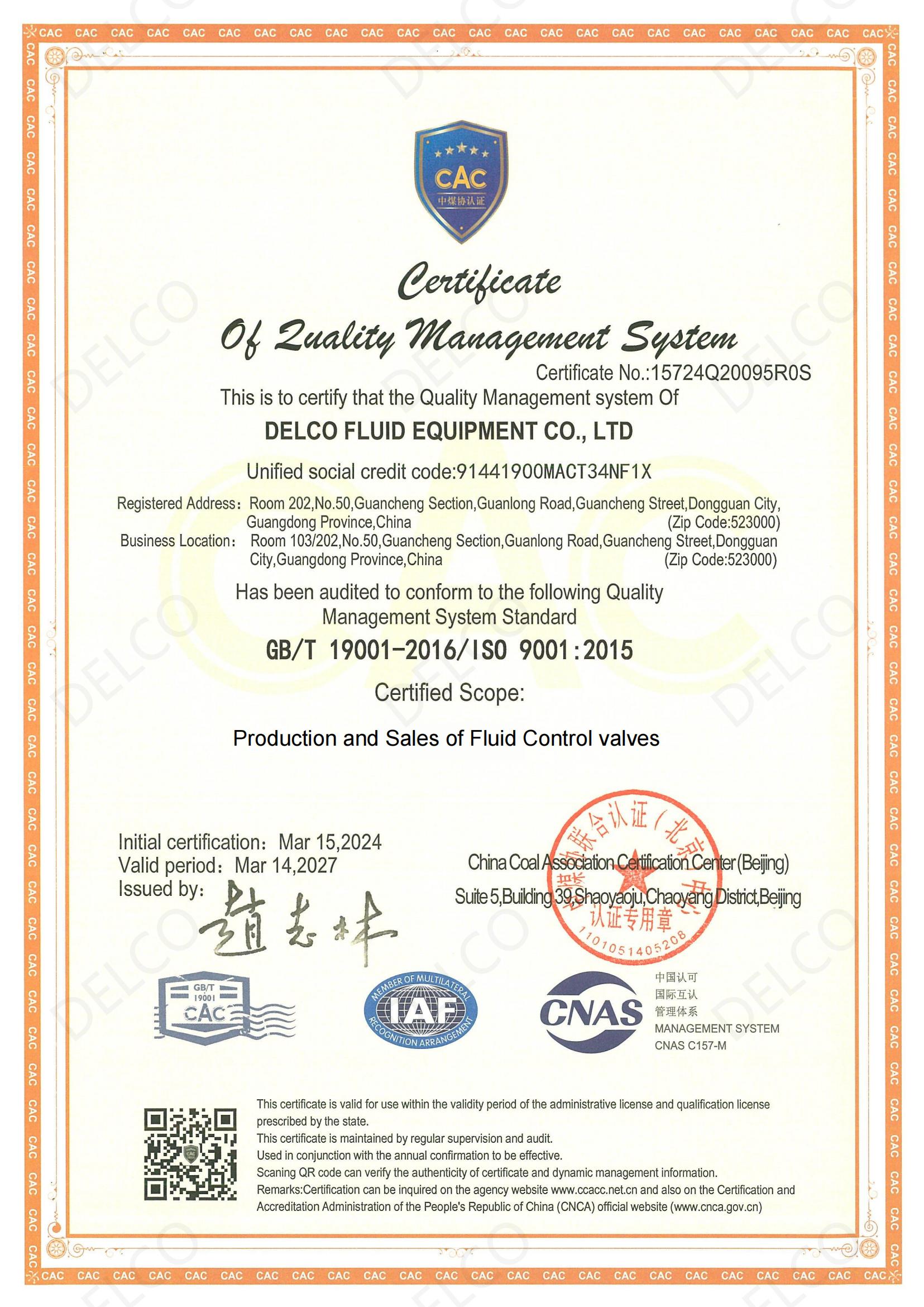

Quality Assurance

Calculation & Selection, Quality Control, Inspection, After-Sales Service, etc. Each Production Loop to Ensure Our Customers Have No Worries.

Services

At DELCO, we believe there always has a better valve solution for every single customer. We’re obsessively passionate about it, and our mission is to manufactures & supply a range of innovative control valves & pressure regulators backed by global service support, thereby guaranteeing zero defects within the shortest lead time.

Production Market

DELCO Has A Wide Reach, Exporting To Over 46 Nations. So We Have A Complete Picture Of The Market. Welcome To Become A Long-Term Business Partner With Us. Reliable Control Valves and Self-Operated Pressure RegulatorsManufacturer

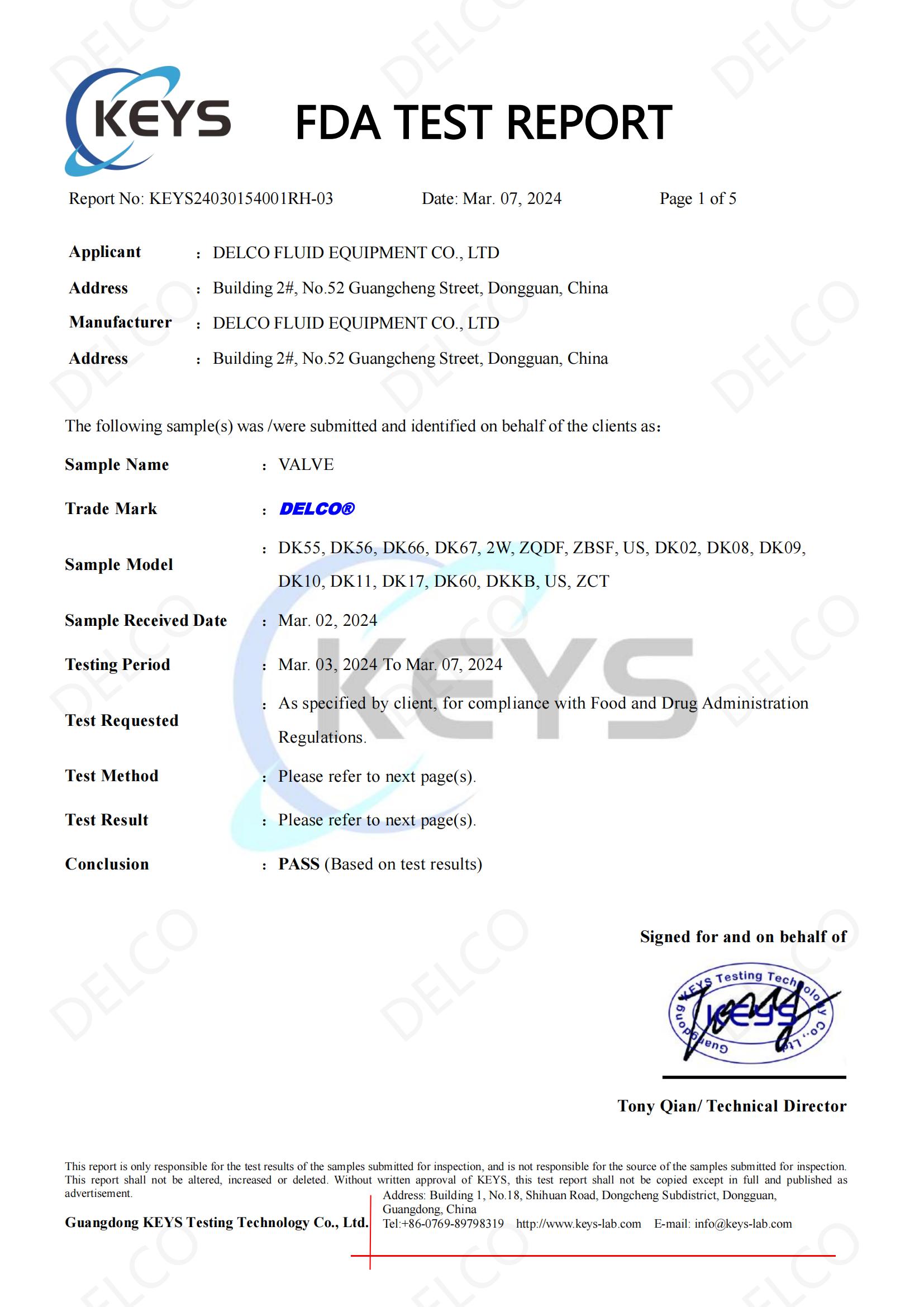

Company Honor

DELCO valve has CE, RoHS, FDA, Explosion-proof electrical apparatus.

For over 20 years, DELCO Valves has been committed to providing our customers with high quality valves.

DELCO has always been centered around one thing: 100% customer satisfaction. We strive for continuous improvement in all aspects of our daily operations. Our mission, coupled with a product line that is manufactured to the highest quality standards, continues to be what sets us apart from our competition. At Powell, all of our facilities are ISO 9001 “Global Quality” certified.

As a leading manufacturer of industrial valves, we offer a wide range of products. Our product lines include: gate valves, check valves, globe valves, check valves, double plate check valves and high performance butterfly valves. With the most complete multi-turn product line from a single-source manufacturer, our valves are manufactured to the highest quality standards using ultra-modern manufacturing techniques and astute material sourcing.

As a full-service valve company, we offer a wide range of products as well as retrofit and field services. Our valve expertise is unrivaled and we look forward to meeting your future valve needs!