Tech Theory: Technical…Practical… Interesting Automation Industrial Solutions

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control air supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Pneumatic Butterfly Valves: Working Principles and Types

Pneumatic butterfly valves are widely used in industrial control systems due to their simple, compact, and cost-effective design. These valves, consisting of a pneumatic actuator and a butterfly valve body, are commonly applied in industries such as oil, natural gas, chemical processing, water treatment, and power generation. Below is a detailed overview of the working principles and classifications of pneumatic butterfly valves.

Table of contents

I. Working Principles of Pneumatic Butterfly Valves

1. Core Structure

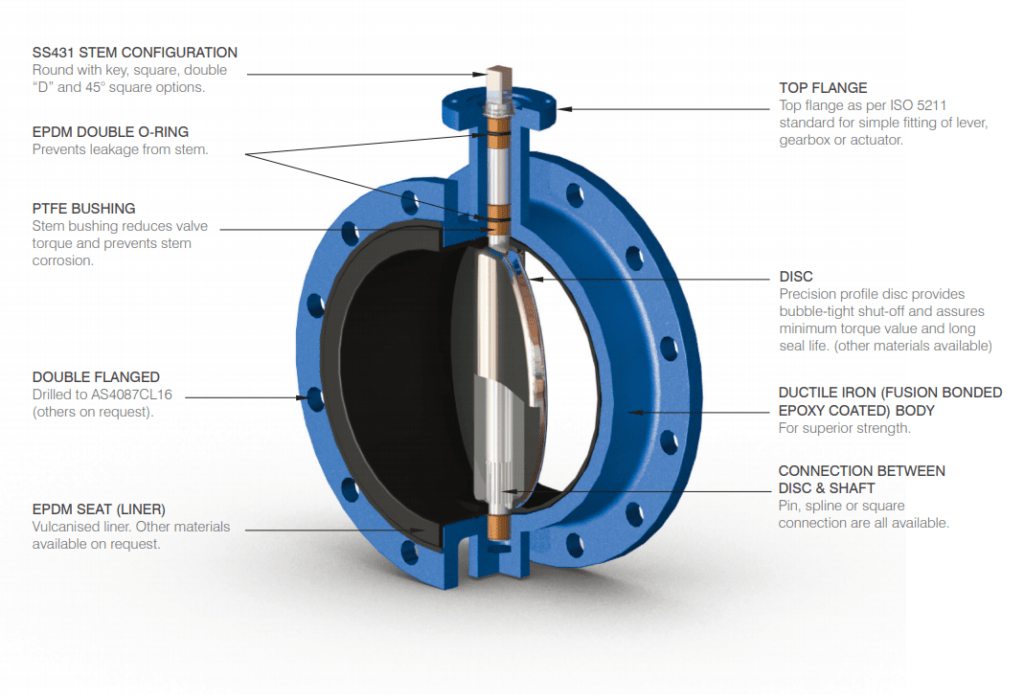

- Butterfly Disc and Shaft: The key components of a pneumatic butterfly valve are the butterfly disc and shaft. The disc is a circular plate that rotates with the shaft to control fluid flow. The angle of rotation determines the valve’s opening degree, allowing flow regulation or complete closure.

- Pneumatic Actuator: The actuator drives the rotation of the butterfly disc. Through a pneumatic control system, including air source, pipelines, and solenoid valves, the actuator precisely and swiftly opens or closes the valve.

2. Ease of Operation

Open/Close Mechanism: The butterfly disc rotates 90 degrees to achieve full open or full closed positions. This design ensures rapid response and simple operation. When fully open, the disc’s thickness is the primary resistance to fluid flow, maintaining a low-pressure drop.

3. Flow Regulation

Control Capability: In addition to on/off control, pneumatic butterfly valves can be used for precise flow regulation. Choosing the correct valve size and type ensures accurate flow control, making it suitable for large-diameter applications.

4. Sealing Types

Sealing Options: Pneumatic butterfly valves offer elastic and metal sealing options. Elastic sealing includes rings embedded in the valve body or around the disc, suitable for standard environments. Metal sealing is used for high-temperature and high-pressure conditions.

II. Types of Pneumatic Butterfly Valves

1. Pneumatic Wafer Butterfly Valves

Design Features: These valves feature a compact design, ideal for installations in confined spaces. Their structure ensures zero external leakage and compliance with national internal leakage standards, making them suitable for various industrial pipelines.

2. Pneumatic Lined Rubber Butterfly Valves

Applications: These valves use flange or clamp connections and feature various types of rubber linings (e.g., nitrile, EPDM, fluororubber) to enhance corrosion and abrasion resistance, suitable for chemical processing.

3. Pneumatic Lined Fluoropolymer Butterfly Valves

Corrosion Resistance: With a fluoropolymer lining, these valves offer exceptional resistance to corrosive media. Their integrated body and seat design can handle strong corrosive substances, making them ideal for chemical and metallurgical industries.

4. Pneumatic Ventilation Butterfly Valves

Environment Suitability: Designed with a thin gap, these valves are suitable for environments with poor air circulation. They effectively regulate airflow in ventilation systems, ensuring efficient ventilation, commonly used in ducting and exhaust systems.

Summary

Pneumatic butterfly valves play a crucial role in industrial control systems due to their simple design and superior performance. Selecting the appropriate type of pneumatic butterfly valve based on specific requirements can enhance system efficiency and reliability. Whether in high-temperature, high-pressure, or corrosive environments, pneumatic butterfly valves demonstrate their unique advantages.

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.