Tech Theory: Technical…Practical… Interesting Automation Industrial Solutions

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control air supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

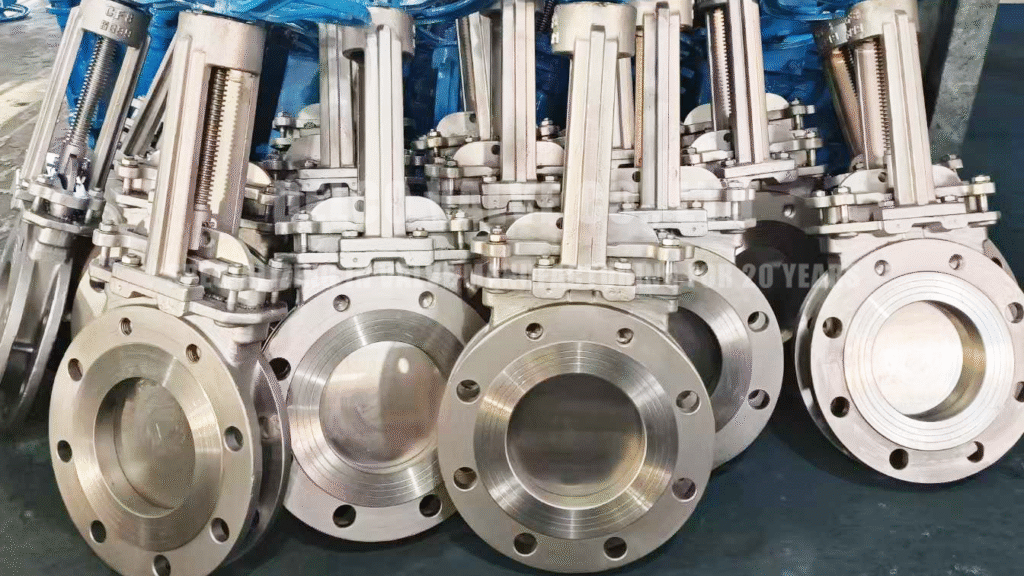

Manual Knife Gate Valve: Ideal for Thick Slurry Processing

The Manual Knife Gate Valve, with its unique knife gate design, is ideal for handling thick slurries and high viscosity fluids. In this article, DELCO Valve will introduce this valve to you from application scenarios, features to maintenance tips.

What is a Manual Knife Gate Valve?

Manual Knife Gate Valve is a kind of valve that controls the opening and closing of the knife gate by manual operation, designed for handling fluids containing solid particles. The knife gate cuts through solid particles in the medium and ensures smooth passage of the fluid.

Working Principle of Manual Knife Gate Valve

Turn the handwheel by hand to make the valve stem rise or fall. This drives the gate plate to make rising and falling movements to realize the purpose of opening or closing the valve. Clockwise rotation of the handwheel, the gate down, the valve is closed. Turning the handwheel counterclockwise, the gate rises and the valve opens.

Main Application Scenarios

- Wastewater treatment: treating sludge containing solid particles and ensuring unobstructed pipeline flow.

- Mining industry: conveying slurry or mud to support high abrasion environments.

- Paper industry: Handling high viscosity pulp to improve productivity.

- Power industry: conveying slag water or high temperature fly ash to meet high temperature and high pressure requirements.

How to properly maintain Manual Knife Gate Valve?

- Clean the surface of the knife gate: Regularly clean the accumulated solid particles to prevent affecting the action of the gate.

- Lubricate key components: Add lubricant to components such as handwheels and valve stems to minimize wear and tear.

- Check seals: Regularly check soft seals for wear to ensure there are no leaks.

Conclusion

Manual Knife Gate Valves are widely used in a variety of industrial scenarios due to their unique design and reliable performance. With proper maintenance and care, users can significantly extend the life of the equipment and improve the efficiency of the system.

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.