Tech Theory: Technical…Practical… Interesting Automation Industrial Solutions

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control air supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

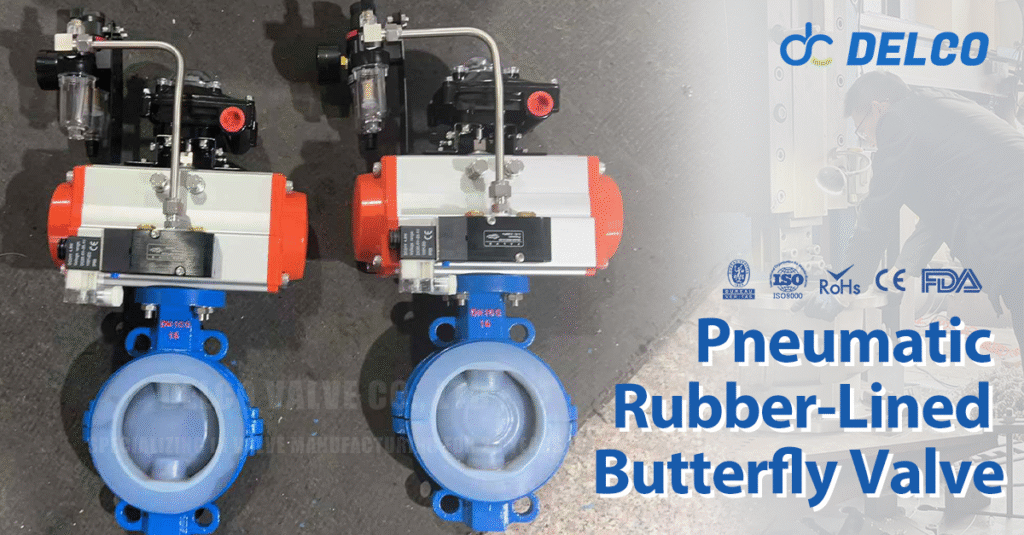

Maintenance and Care Guide for Pneumatic Butterfly Valves

Pneumatic Butterfly Valves are commonly used in industrial fluid control, and their fast response and efficient operation have made them a core piece of equipment in a variety of industries. However, in order to ensure the long-term stable operation of the valve, regular maintenance and repair are essential. In this article, DELCO Valve will introduce the common problems, maintenance methods and specific recommendations for extending the life of pneumatic butterfly valves.

Common Causes of Failure

- Gate Stuck: Due to impurities or deposits in the medium, the gate cannot open or close smoothly.

- Seal wear: after long-term use, the soft seals may fail due to aging at high pressure or high temperature.

- Pneumatic actuator failure: Insufficient pressure from the air source or wear inside the actuator leads to slow action.

- Corrosion problems: Exposed to corrosive media or environment, the valve body and key components may be damaged.

Routine Maintenance and Care Methods

- Regular cleaning: Remove dirt and deposits on the surface and inside of the valve, especially under conditions of handling media containing particles, to avoid accumulation of impurities leading to jamming.

- Lubricate critical parts: Apply lubricant to the shaft and seals regularly to minimize wear and improve smooth operation.

- Inspect seals: Regularly inspect soft seals for wear and replace them when deterioration or cracks are found to prevent media leakage.

- Test pneumatic actuators: Test the sensitivity of pneumatic actuators to ensure rapid action response and check whether the air source pressure is stable.

- Anti-corrosion protection: For valves exposed to corrosive environments, it is recommended to apply anti-corrosion coating on a regular basis, or use corrosion-resistant materials (such as stainless steel or rubber-lined materials).

Suggestions to Extend the Service Life of the Valve

- Follow the manufacturer’s operating instructions and avoid using the valve beyond its design pressure or temperature range.

- Operate the valve periodically, even during prolonged shutdowns, to prevent components from failing due to prolonged quiescence.

- Monitor changes in operating conditions and promptly adjust valve settings to accommodate changes in media pressure, temperature or flow rate.

Key Precautions

- Ensure that the environment around the valve is clean, to avoid dust or impurities into the pneumatic actuator.

- Keep commonly used seals and lubricants on hand for quick replacement and maintenance.

- Complex faults need to contact professional technicians for diagnosis and repair.

Conclusion

Regular cleaning, lubrication, seal inspection and testing of pneumatic actuators can significantly extend the life of Pneumatic Butterfly Valves and reduce the incidence of failure. Proper maintenance not only improves equipment operating efficiency, but also reduces long-term operating costs.

Contact DELCO For Quick Quote

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email [email protected].

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.