Tech Theory: Technical…Practical… Interesting Automation Industrial Solutions

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control air supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

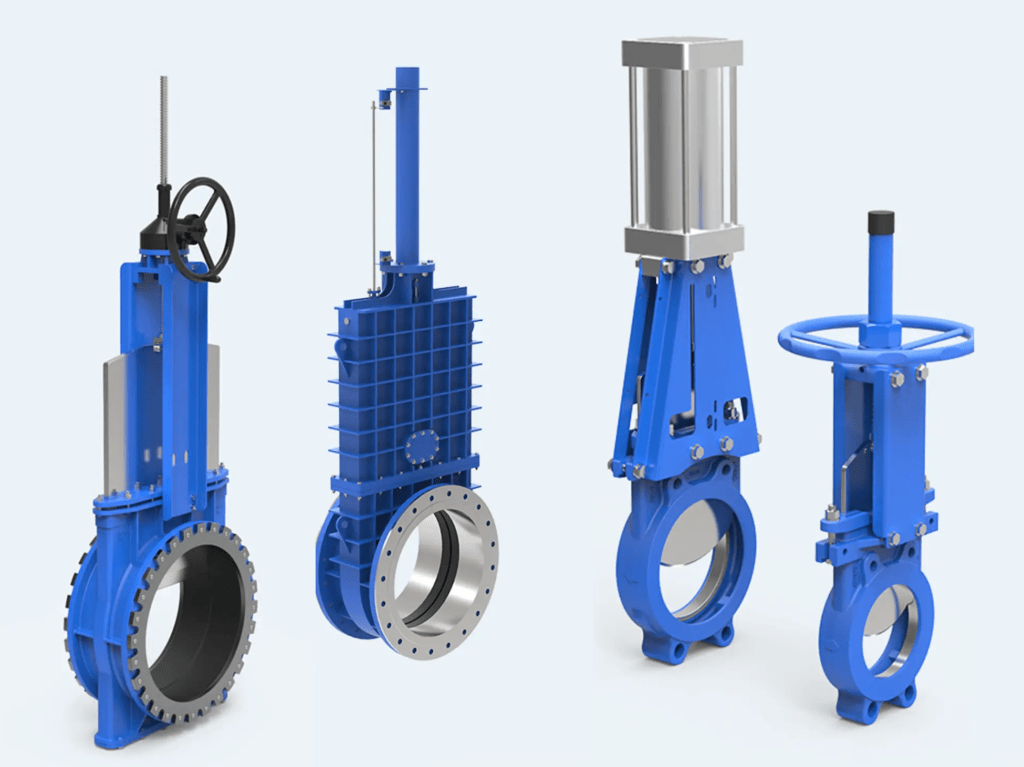

Knife gate valve is a special type of gate valve, which is widely used in a variety of industrial fields due to its unique structure and superior performance. In this article, DELCO Valve will share the working principle, structural features and application scenarios of knife gate valves.

Knife Gate Valve Working Principle

The working principle of knife gate valve is based on the opening and closing movement of its gate. The valve’s gate moves vertically and is connected to an actuator (manual, electric, or pneumatic device) via a stem. When the gate is lowered, the gate fits tightly against the valve seat, closing the valve and preventing the passage of fluid. Conversely, when the gate rises, the valve opens and the fluid flows smoothly.

Knife Gate Valve Structural Characteristics

- Simple and compact structure: The structure of the knife gate valve is relatively simple, the main components include the valve body, gate, stem, seals and actuator. This simple design makes it easy to manufacture, install and maintain.

- Excellent sealing performance: The sealing surface between the gate and the valve seat of the knife gate valve is usually precision machined to ensure that a reliable seal can be formed in the closed state to prevent fluid leakage.

- Flexible and reliable operation: Knife gate valves have various actuators, which can be operated manually or remotely by electric or pneumatic devices, making the operation flexible and reliable.

- Wear-resistant and corrosion-resistant: The gate and seat materials of knife gate valves are usually made of wear-resistant and corrosion-resistant alloy steel, stainless steel, or special coating materials to adapt to a variety of harsh working environments.

- Strong applicability: The knife gate valve is suitable for a variety of fluid media, including liquids, gases and media containing solid particles. Its gate design can effectively cut solid particles to avoid clogging.

Knife Gate Valves Applications

- Industrial Wastewater Treatment: Knife gate valves are used to interrupt and regulate wastewater flow, and their corrosion and abrasion resistance allows them to handle corrosive materials and solids in wastewater.

- Coal and Ore Conveying: Knife gate valves are used to control the flow of materials, and their robust construction and gate design that cuts through solid particles makes them excellent for handling high concentrations of solids.

- Food and Pharmaceutical: Knife gate valves are used to control the flow of fluids, and their sealing performance and hygienic design enable them to meet high cleanliness requirements, ensuring product quality and safety.

- Power and water treatment: Knife gate valves are used to control the flow of cooling water, circulating water and chemical additives, and their reliable sealing performance and temperature resistance enable them to work stably in high-pressure and high-temperature environments.

- Construction and Municipal Engineering: Knife gate valves are used to control the flow of sewage, rainwater and other fluids, and their simple structure and easy maintenance make them suitable for long-term use.

Get Quick Quote From DELCO Valve

DELCO Valve is a world-leading valve manufacturer that specialized in actuated valves and control valves with rich experience for 20 years. DELCO originated from German technology, has its own R&D, design, production, sales team, and aims to be the global automatic application service provider.

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email [email protected].

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.