技術理論: 技術的…実践的…興味深い自動化産業ソリューション

DELCO では、顧客満足の重要性を理解し、すべてのクライアントの独自のニーズを満たすよう努めています。信頼できるバルブ サプライヤーとして、当社は優れた顧客サービスと高品質の製品を提供し、最適なパフォーマンスと長寿命を確保することに尽力しています。信頼できる制御空気サプライヤーとして DELCO を選択すると、要件に合わせて特別に設計されたカスタマイズされたバルブ アセンブリのメリットが得られ、効率が向上し、ダウンタイムが短縮されます。

マルチターン電動バルブの探究: 知っておくべきこと

導入

産業オートメーションと流体制御システムに関しては、マルチターン モーター バルブは不可欠なコンポーネントです。これらのバルブは、水処理、HVAC システム、化学処理、発電など、さまざまなアプリケーションで液体、ガス、その他の材料の流れを調節するために不可欠です。この記事では、マルチターン モーター バルブの詳細について説明し、その機能、タイプ、アプリケーション、利点、およびニーズに合った適切なバルブを選択するための重要な考慮事項について説明します。

マルチターン電動バルブとは何ですか?

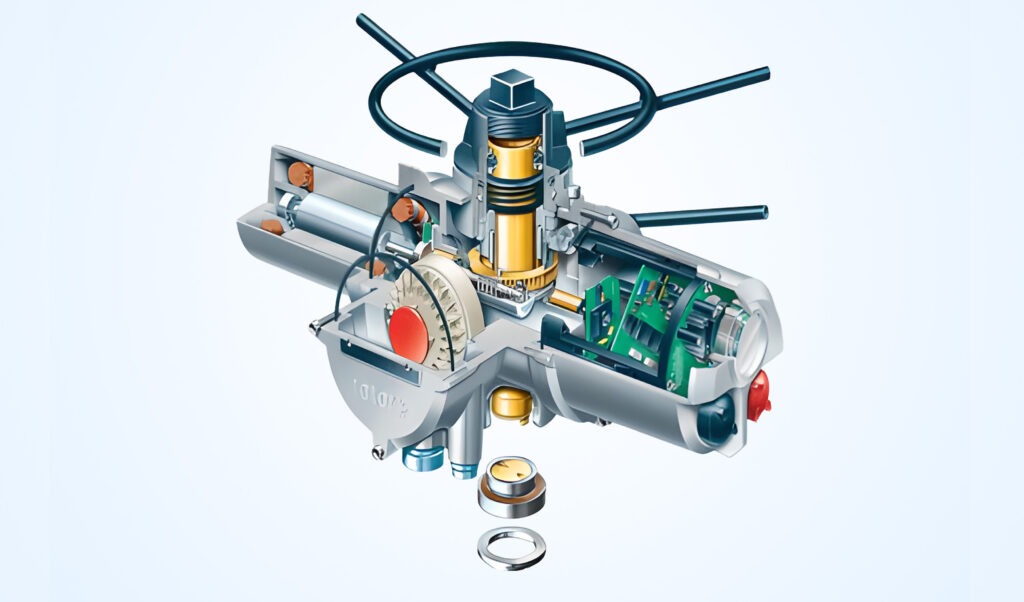

多回転電動バルブ バルブ ステムを複数回回転させてバルブを完全に開閉することで、媒体の流れを制御するように設計された自動化デバイスです。90 度の回転のみを必要とする 1/4 回転バルブとは異なり、マルチ ターン バルブは完全に開いた状態から完全に閉じた状態に移行するのに数回の回転が必要です。この設計により、流量を正確に制御できるため、微調整が必要な用途に最適です。

多回転電動バルブのコンポーネント

バルブ本体: 内部コンポーネントを収容し、流体の経路を提供する主要構造。

バルブステム: アクチュエータをバルブ ディスク、ゲート、またはプラグに接続し、バルブを開閉する動きを伝達するロッド。

アクチュエータ: バルブ ステムを駆動する電動機構。電気式、空気圧式、油圧式があります。

ディスク、ゲート、プラグ: バルブを通る流れを調節するために動く内部部品。

シールとガスケット: これらのコンポーネントは、流体がバルブ本体から漏れるのを防ぎ、漏れのない動作を保証します。

多回転電動バルブの種類

ゲートバルブ: 流れのオン/オフ制御に使用され、上下に動いて流路を開閉するゲート (くさび) を備えています。

グローブバルブ: スロットル アプリケーションに最適なこの製品には、固定リング シートに対する位置を変更することで流量を調整する可動ディスク (またはプラグ) が備わっています。

ダイヤフラムバルブ: 上下に動く柔軟なダイヤフラムを利用して流れを制御します。これらは、汚染のない操作を必要とするアプリケーションでよく使用されます。

ニードルバルブ: 円錐形のシートにフィットする針状のプランジャーを使用して、正確な流量制御を実現します。

マルチターン電動バルブの仕組み

多回転電動バルブ 電気、空気圧、または油圧アクチュエータの回転運動を直線運動に変換してバルブ ステムを動かします。アクチュエータは、通常はリモート コントロール システムから制御信号を受信し、バルブ ステムを複数回回転させて目的の位置に到達します。この精密な制御メカニズムにより、正確な流量制御を必要とするアプリケーションに適しています。

電動アクチュエータ

電動アクチュエータは、マルチターン電動バルブで使用される最も一般的なタイプです。電動アクチュエータは電動モーターで駆動され、コントロール パネルまたは自動化システムを介してリモート制御できます。電動アクチュエータには、正確な制御、制御システムとの簡単な統合、メンテナンス要件の低さなど、いくつかの利点があります。

空気圧アクチュエータ

空気圧アクチュエータは、圧縮空気を使用してバルブ ステムを駆動します。爆発性雰囲気など、電気アクチュエータが危険を及ぼす可能性がある環境では、空気圧アクチュエータが好まれます。空気圧アクチュエータは応答時間が速く、出力が大きいことで知られており、高負荷の用途に適しています。

油圧アクチュエータ

油圧アクチュエータは加圧された油圧流体を使用して作動します。過酷な条件でも、高い力と正確な制御を提供できます。油圧アクチュエータは、スペースの制約や環境要因により電気式または空気圧式アクチュエータが適さないアプリケーションでよく使用されます。

マルチターン電動バルブの用途

マルチターン電動バルブは、その汎用性と精度により、幅広い業界や用途で使用されています。一般的な用途には次のようなものがあります。

水と廃水処理

水処理場や廃水処理場では、さまざまな処理プロセスで水の流れを制御するために、多回転電動バルブが使用されています。これらのバルブは、処理プロセスの効率と効果を維持するために不可欠な、流量の正確な調整を保証します。

HVAC システム

暖房、換気、空調 (HVAC) システムは、システム内の空気と水の流れを調節するために、多回転電動バルブを使用しています。これらのバルブは、最適な温度と湿度レベルを維持し、快適な室内環境を確保します。

化学処理

化学処理工場では、最終製品の品質と一貫性を維持するために、流体の流れを正確に制御することが重要です。マルチターン電動バルブは、製造のさまざまな段階で化学物質の流れを管理するために必要な精度と信頼性を提供します。

発電

発電所では、蒸気、水、その他の流体の流れを制御するために、多回転電動バルブを使用しています。これらのバルブは、プラント内の圧力と温度を調節し、安全で効率的な運転を確保する上で重要な役割を果たします。

石油・ガス産業

石油・ガス業界では、原油、天然ガス、その他の炭化水素の流れを制御するために、多回転電動バルブが使用されています。これらのバルブは、生産、輸送、精製のさまざまな段階で使用され、プロセスの正確な制御と安全性の確保を実現します。

マルチターン電動バルブを選択する際に考慮すべき重要な点

選択する場合 多回転電動バルブ アプリケーションでは、最適なパフォーマンスと信頼性を確保するために、いくつかの要素を考慮する必要があります。

バルブタイプ

アプリケーションの特定の要件に基づいて、適切なバルブ タイプ (ゲート、グローブ、ダイヤフラム、またはニードル) を選択します。各タイプには独自の利点があり、さまざまなフロー制御タスクに適しています。

アクチュエータタイプ

アプリケーションに最適なアクチュエータのタイプ (電動、空気圧、油圧) を検討してください。電動アクチュエータは精密な制御と自動化に最適ですが、空気圧および油圧アクチュエータは過酷な環境や危険な環境に適しています。

材料の適合性

バルブの材質が制御対象の媒体と互換性があることを確認します。たとえば、ステンレス鋼バルブは腐食性流体に適しており、UPVC バルブは水および廃水処理用途に最適です。

圧力および温度定格

バルブがアプリケーションの動作圧力と温度条件に対応できることを確認します。適切な定格のバルブを選択すると、安全で信頼性の高いパフォーマンスが保証されます。

制御システム統合

バルブを制御システムにどのように統合するかを検討してください。アクチュエータが既存の制御インフラストラクチャと互換性があり、リモート操作用に簡単にプログラムできることを確認してください。

結論

マルチターン モーター バルブは、現代の産業オートメーションおよび流体制御システムに欠かせないコンポーネントです。正確な流量調整、リモート コントロール、信頼性の高いパフォーマンスを提供できるため、幅広い用途に最適です。マルチターン モーター バルブのさまざまなタイプ、機能、利点を理解することで、特定のニーズに適したバルブを選択する際に十分な情報に基づいた決定を下すことができます。適切な選択を行うことで、産業プロセスの効率、安全性、信頼性を高め、長期的な成功と生産性を確保できます。

産業用バルブの見積りをすぐに取得するにはどうすればいいですか?

バルブについてご質問がある場合、または見積もりをご希望の場合は、お気軽にお問い合わせください。6 時間以内に返信いたします。電話 +86 159 8960 2972、WhatsApp +86 159 8960 2972、またはメール [email protected] までご連絡ください。

DELCO は、その品質、競争力のある価格、優れたサービスにより、お客様のビジネスの成長を支援する最高のバルブ パートナーとなっています。バルブをカスタマイズできます。最小注文数はありません。

DELCO では、顧客満足の重要性を理解し、すべてのクライアントの独自のニーズを満たすよう努めています。信頼できるコントロール バルブ サプライヤーとして、当社は優れた顧客サービスと高品質の製品を提供し、最適なパフォーマンスと長寿命を確保することに尽力しています。信頼できるコントロール バルブ サプライヤーとして DELCO を選択すると、要件に合わせて特別に設計されたカスタマイズされたバルブ アセンブリのメリットが得られ、効率が向上し、ダウンタイムが短縮されます。

さらに、当社の電子圧力調整器は価格競争力があるため、一流のソリューションを提供できます。大手コントロールバルブメーカーの 1 つとして、当社は業界標準を満たすだけでなく、お客様のビジネス全体の収益性にも貢献する信頼性の高いバルブをお届けすることに誇りを持っています。DELCO と提携することで、会社の長期的な成功のために賢明な選択をしているという安心感を得ることができます。