技術理論: 技術的…実践的…興味深い自動化産業ソリューション

DELCO では、顧客満足の重要性を理解し、すべてのクライアントの独自のニーズを満たすよう努めています。信頼できるバルブ サプライヤーとして、当社は優れた顧客サービスと高品質の製品を提供し、最適なパフォーマンスと長寿命を確保することに尽力しています。信頼できる制御空気サプライヤーとして DELCO を選択すると、要件に合わせて特別に設計されたカスタマイズされたバルブ アセンブリのメリットが得られ、効率が向上し、ダウンタイムが短縮されます。

電動バタフライバルブ、電動ボールバルブ、電動2方弁の分解手順

産業および建設の分野では、電動バルブの応用が広範かつ重要です。デルコフルイドのバルブ製造業者は、電動バタフライ バルブ、電動ボール バルブ、電動双方向バルブのメンテナンスと維持のために適切な分解が重要であることを十分に認識しています。以下では、これら 3 種類のバルブの分解手順について詳しく説明します。

1、電動バタフライバルブの分解手順

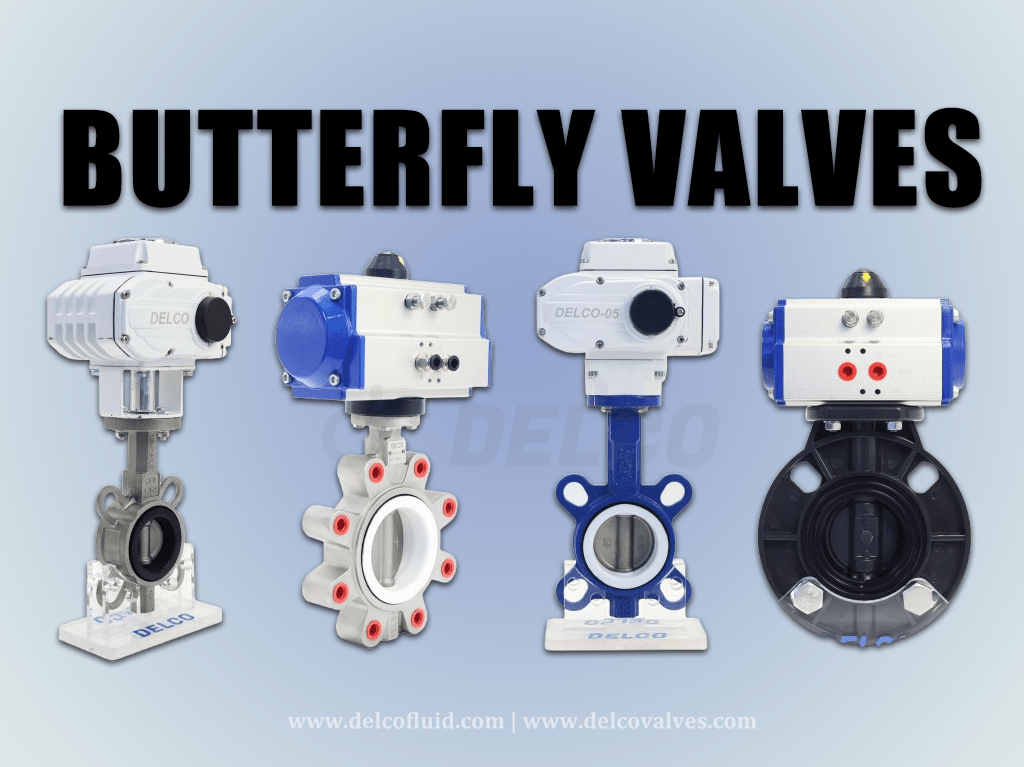

電動バタフライバルブは、コンパクトな構造、簡単な操作、優れた密閉性能で知られており、商業ビル、公共ビル、都市パイプラインの給水システムや換気システムに広く使用されています。分解するときは、次の手順に従ってください。

(1)停電と排気:まず、バルブの電源がオフになっていることを確認し、上流バルブと下流バルブを閉じて、パイプライン内の圧力と残留媒体を放出します。

(2)アクチュエータの分解:工具を使用してアクチュエータとバルブ本体間の接続ボルトを緩め、アクチュエータをバルブ本体から慎重に分離します。

(3)バルブステムとバタフライプレートを分解する:専用工具を使用して、バルブステムナットをゆっくりと回転させ、バルブステムとバタフライプレートアセンブリをバルブボディから取り出します。

(4)検査と清掃:バルブシート、バタフライプレート、シールリングの摩耗を慎重に検査し、必要に応じて交換します。同時に、バルブ本体の内壁とすべての部品を清掃して、不純物が残っていないことを確認します。

2、電動ボールバルブの分解手順

電動ボールバルブは、高精度の流量制御と長期にわたる密閉性能により、HVAC 水システムで重要な役割を果たします。分解するときは、以下の手順に従ってください。

(1)停電と隔離:同様に、バルブの電源がオフになっていることを確認し、上流バルブと下流バルブを閉じ、パイプラインを排水します。

(2)フランジまたはねじ接続部の分解:バルブの接続方法(フランジまたはねじ)に応じて、対応する工具を使用して接続部を緩め、バルブを配管システムから分離します。

(3)バルブコアの取り外し:バルブシートとシーリングリングを損傷しないように注意しながら、バルブステムをゆっくり回転させてバルブコアをバルブボディから取り外します。

(4)保守点検:バルブコア、バルブシート、シールリングの摩耗を確認し、必要に応じて交換または修理します。すべての部品を清掃して、不純物がないことを確認します。

3、電動二方弁の分解手順

電動双方向バルブは、スプリングリセット、手動過負荷制御、配線の容易さなどの特徴から、セントラル空調および暖房システムの温度制御に広く使用されています。分解するときは、次の手順に従ってください。

(1)停電と準備:バルブの電源がオフになっていることを確認し、上流バルブと下流バルブを閉じ、パイプラインの圧力を解放します。

(2)アクチュエータの分解:ドライバーなどの工具を使用してアクチュエータハウジングを慎重に分解し、内部の伝達機構を露出させます。

(3)バルブステムとバルブボディを分離する:バルブステムナットをゆっくり回して、バルブステムとバルブコアアセンブリをバルブボディから取り外します。

(4)点検とメンテナンス:バルブコア、バルブシート、シールリングの摩耗を確認し、必要に応じて交換します。すべての部品を清掃し、異物が残っていないことを確認します。

(5)回収と試験:分解と逆の順序でバルブを組み立て直し、機能試験を実施してバルブが正常に動作することを確認します。

Delcofluid バルブ製造業者は、分解作業を行う前にバルブの構造特性と分解手順を十分に理解し、事故を防ぐために適切な安全対策を講じるよう注意喚起しています。同時に、バルブの定期的なメンテナンスと保守により、バルブの耐用年数が大幅に延び、システム全体の運用効率が向上します。

産業用バルブの見積りをすぐに取得するにはどうすればいいですか?

バルブについてご質問がある場合、または見積もりをご希望の場合は、お気軽にお問い合わせください。6 時間以内に返信いたします。電話 +86 159 8960 2972、WhatsApp +86 159 8960 2972、またはメール [email protected] までご連絡ください。

DELCO は、その品質、競争力のある価格、優れたサービスにより、お客様のビジネスの成長を支援する最高のバルブ パートナーとなっています。バルブをカスタマイズできます。最小注文数はありません。

DELCO では、顧客満足の重要性を理解し、すべてのクライアントの独自のニーズを満たすよう努めています。信頼できるコントロール バルブ サプライヤーとして、当社は優れた顧客サービスと高品質の製品を提供し、最適なパフォーマンスと長寿命を確保することに尽力しています。信頼できるコントロール バルブ サプライヤーとして DELCO を選択すると、要件に合わせて特別に設計されたカスタマイズされたバルブ アセンブリのメリットが得られ、効率が向上し、ダウンタイムが短縮されます。

さらに、当社の電子圧力調整器は価格競争力があるため、一流のソリューションを提供できます。大手コントロールバルブメーカーの 1 つとして、当社は業界標準を満たすだけでなく、お客様のビジネス全体の収益性にも貢献する信頼性の高いバルブをお届けすることに誇りを持っています。DELCO と提携することで、会社の長期的な成功のために賢明な選択をしているという安心感を得ることができます。