Teori Teknologi: Teknis…Praktis… Solusi Industri Otomasi yang Menarik

Di DELCO, kami memahami pentingnya kepuasan pelanggan dan berusaha memenuhi kebutuhan unik setiap klien. Sebagai pemasok katup yang andal, kami berkomitmen untuk menyediakan layanan pelanggan yang sangat baik dan produk berkualitas tinggi untuk memastikan kinerja dan keawetan yang optimal. Dengan memilih DELCO sebagai pemasok udara kontrol tepercaya, Anda dapat memperoleh manfaat dari rakitan katup yang disesuaikan yang dirancang khusus untuk memenuhi kebutuhan Anda, meningkatkan efisiensi, dan mengurangi waktu henti.

Mengapa Memilih Katup Bola Bawah?

Perkenalan

Dalam industri modern, bejana reaksi merupakan komponen penting dalam proses produksi kimia, farmasi, bioteknologi, dan pangan. Mengoptimalkan sistem pembuangan bejana ini untuk memastikan pembuangan material yang efisien dan kebersihan sangat penting untuk meningkatkan efisiensi produksi dan memastikan kualitas produk. Bagian bawah katup bola, dengan kinerjanya yang luar biasa dan desain yang inovatif, telah menjadi elemen kunci dalam berbagai industri bersih. Artikel ini membahas aplikasi dan fitur desain katup bola bawah untuk memberikan pemahaman menyeluruh tentang mengapa katup ini sangat disukai dalam industri.

Daftar isi

Aplikasi Katup Bola Bawah

Dasar katup bola banyak digunakan dalam industri bersih seperti farmasi, bioteknologi, bahan kimia halus, dan pengolahan makanan. Industri-industri ini memiliki persyaratan ketat untuk kebersihan peralatan, efisiensi pembuangan material, dan kinerja penyegelan. Berikut ini adalah cara katup bola bawah memenuhi kebutuhan ini di berbagai bidang:

1. Industri Farmasi

Dalam industri farmasi, katup bola bawah meningkatkan keamanan dan efisiensi produksi. Desain katup memastikan tidak ada residu material, yang mencegah kontaminasi silang, dan menjaga kemurnian obat-obatan. Kinerja penyegelannya yang sangat baik memenuhi standar kebersihan yang ketat yang diperlukan untuk proses produksi obat, memastikan produk farmasi berkualitas tinggi dan aman.

2. Bioteknologi

Sektor bioteknologi melibatkan berbagai reaksi biologis dan proses budidaya, yang membutuhkan standar kebersihan dan kemudahan pengoperasian yang tinggi. Katup bola bawah ideal untuk digunakan dalam bioreaktor karena desainnya yang rendah residu dan perawatannya yang mudah. Katup ini memastikan pembuangan material secara menyeluruh dan menyederhanakan pembersihan, sehingga meningkatkan efisiensi produksi dan memastikan kualitas serta keamanan bioproduk.

3. Bahan Kimia Halus

Dalam industri kimia halus, di mana bahan kimia bernilai tinggi dan reaksi kompleks merupakan hal yang umum, katup bola bawah unggul. Desain lubang penuhnya meminimalkan retensi material di dalam katup, mengurangi kehilangan material dan kontaminasi silang. Desain ini juga memudahkan pembersihan dan perawatan, meminimalkan waktu henti, dan meningkatkan efisiensi produksi secara keseluruhan.

4. Pengolahan Makanan

Pengolahan makanan menuntut standar kebersihan dan higiene yang luar biasa. Katup bola bawah memenuhi kebutuhan ini dengan fitur anti bocor dan bebas residu. Katup ini memastikan pembuangan material yang higienis dan mematuhi standar keamanan pangan yang ketat, sehingga meningkatkan kualitas dan keamanan produk makanan.

Fitur Desain Katup Bola Bawah

Katup bola bawah hadir dengan beberapa fitur desain unik yang membuatnya menonjol dalam berbagai aplikasi. Berikut ini adalah penjelasan terperinci mengenai aspek desain tersebut:

1. Daerah Residu Rendah

Desain area residu rendah memastikan bahwa material dibuang sepenuhnya dengan residu minimal. Fitur ini penting dalam industri yang membutuhkan kebersihan tinggi, seperti farmasi dan pengolahan makanan, dan menyederhanakan pembersihan dan perawatan katup, sehingga mengurangi risiko kontaminasi.

2. Jalur Aliran Langsung

Desain jalur aliran langsung mengurangi hambatan aliran material di dalam katup, sehingga meningkatkan efisiensi pembuangan. Desain ini memastikan aliran material lancar, baik saat menangani cairan maupun zat granular, dan meminimalkan gesekan dan kehilangan selama produksi.

3. Desain Bore Penuh

Desain lubang penuh menjaga diameter internal katup agar konsisten dengan jalur pipa, sehingga terhindar dari kehilangan tekanan dan pengurangan aliran. Desain ini meningkatkan laju aliran dan efisiensi fluida sekaligus mengurangi konsumsi energi, sehingga ideal untuk aplikasi yang membutuhkan laju aliran tinggi.

4. Struktur Flensa Tengah

Struktur flens tengah memudahkan pembongkaran dan perawatan katup. Desain ini memungkinkan penggantian atau perbaikan komponen penyegel dengan cepat, mengurangi biaya dan waktu perawatan, serta meningkatkan keawetan katup.

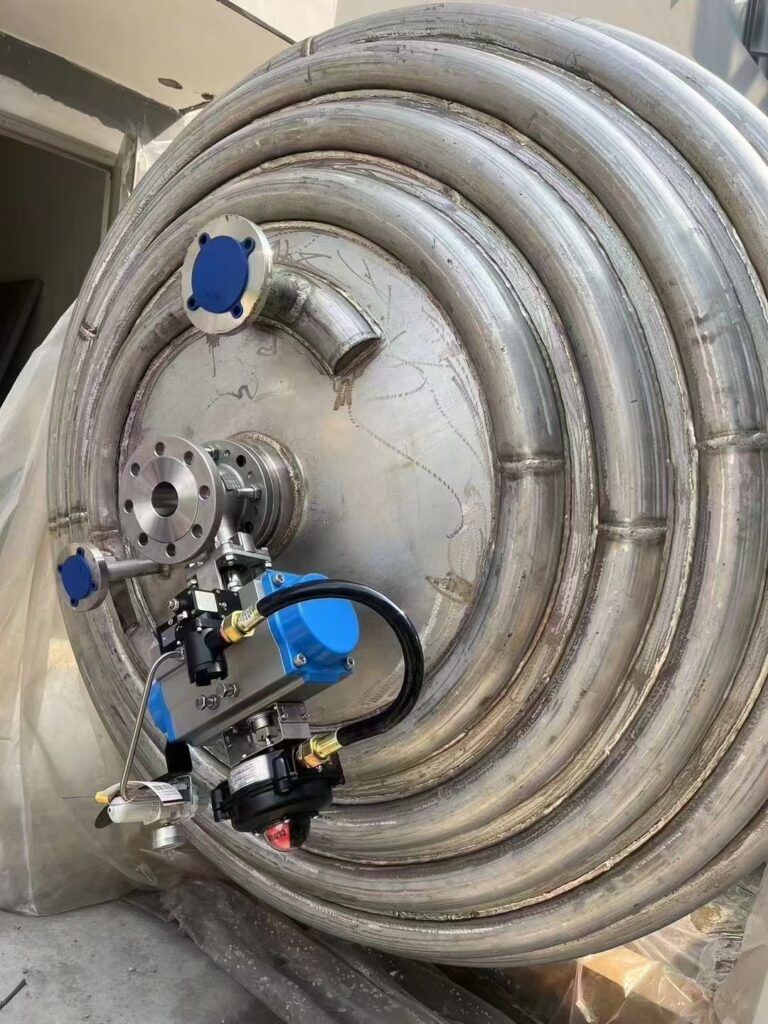

5. Desain Batang Katup Sudut

Desain batang katup bersudut yang inovatif meminimalkan gangguan antara aktuator dan bejana reaktor. Desain ini mengurangi kebutuhan ruang pemasangan dan menyederhanakan perawatan dan perbaikan, serta menawarkan opsi tata letak peralatan yang lebih fleksibel.

6. Struktur Kompak

Desain yang kompak dan terpadu meningkatkan stabilitas dan keandalan katup. Desain ini mengurangi penggunaan ruang, sehingga cocok untuk lingkungan dengan ruang terbatas, dan meningkatkan daya tahan serta kinerja jangka panjang.

7. Platform Pemasangan Langsung ISO5211

Standar platform pemasangan langsung ISO5211 memungkinkan katup terhubung langsung dengan berbagai aktuator tanpa adaptor tambahan. Desain ini menyederhanakan pemasangan, meningkatkan kompatibilitas sistem, dan mempersingkat waktu integrasi.

8. Struktur Pelat Tekanan Pengepakan

Struktur pelat tekanan pengepakan memastikan penyegelan pengepakan katup yang andal. Fitur ini mempertahankan penyegelan yang efektif selama pengoperasian, mengurangi risiko kebocoran, dan menyederhanakan perawatan dan penggantian pengepakan.

Kesimpulan

Katup bola bawah, dengan desain pembuangan tanpa residu, jalur aliran langsung, dan struktur lubang penuh, unggul dalam industri farmasi, bioteknologi, bahan kimia halus, dan pengolahan makanan. Fitur-fiturnya yang inovatif meningkatkan efisiensi pembuangan material, menyederhanakan perawatan, dan memberikan kemudahan operasional yang luar biasa. Memilih katup bola bawah berarti peningkatan efisiensi produksi, biaya perawatan yang lebih rendah, dan kinerja yang unggul, menjadikannya aset yang berharga untuk aplikasi industri.

Didirikan pada tahun 2011, DELCO merupakan pemimpin global di sektor industri. Produk utama kami meliputi katup aktuator elektrik, katup aktuator pneumatik, aktuator otomasi, dan katup solenoida. Selama hampir 20 tahun, kami telah memanfaatkan produk, keahlian teknik, dan solusi otomasi industri kami untuk memecahkan berbagai masalah proyek industri bagi pelanggan kami, termasuk proyek makanan, minuman, kimia, pengolahan air, farmasi, gas alam, minyak, dan HVAC. Saat ini kami memiliki lima anak perusahaan dan lebih dari 50 distributor di seluruh dunia yang menyediakan layanan respons cepat.

Semua produk DELCO menjalani proses desain, rekayasa, dan manufaktur internal 100% yang dipimpin oleh teknisi yang sangat terampil dan berpengalaman dengan menggunakan teknologi Italia dan Jerman untuk memproduksi katup, aktuator, dan solusi berkualitas tinggi, aman, andal, dan bernilai ekonomis. Standar manufaktur dapat dibuktikan dengan sertifikasi yang diperoleh selama bertahun-tahun.

Dan dengan sertifikasi Sistem Manajemen Mutu ISO 9001:2015 serta banyak sertifikasi lain seperti: SGS, RoHS, CNEX, TUV, CE, FDA. Sertifikasi ini membuktikan bahwa DELCO mematuhi standar kualitas dan keamanan tertinggi di seluruh dunia saat memproduksi produknya.

Jika Anda memiliki pertanyaan tentang katup atau ingin mendapatkan penawaran harga, jangan ragu untuk menghubungi kami, kami akan membalas dalam waktu 6 jam. Telepon +86 159 8960 2972, WhatsApp +86 159 8960 2972 atau email marketing [email protected].

Kualitas, harga yang kompetitif, dan layanan yang sangat baik dari DELCO menjadikannya mitra katup terbaik untuk membantu Anda mengembangkan bisnis. Sesuaikan katup Anda, kami tidak memiliki pesanan minimum.

Di DELCO, kami memahami pentingnya kepuasan pelanggan dan berusaha memenuhi kebutuhan unik setiap klien. Sebagai pemasok katup kontrol yang andal, kami berkomitmen untuk menyediakan layanan pelanggan yang sangat baik dan produk berkualitas tinggi untuk memastikan kinerja dan keawetan yang optimal. Dengan memilih DELCO sebagai pemasok katup kontrol tepercaya, Anda dapat memperoleh manfaat dari rakitan katup yang disesuaikan yang dirancang khusus untuk memenuhi kebutuhan Anda, meningkatkan efisiensi, dan mengurangi waktu henti.

Lebih jauh lagi, harga kompetitif kami pada regulator tekanan elektronik memungkinkan Anda menawarkan solusi terbaik. Sebagai salah satu produsen katup kontrol terkemuka, kami bangga dalam menyediakan katup andal yang tidak hanya memenuhi standar industri tetapi juga berkontribusi pada profitabilitas bisnis Anda secara keseluruhan. Dengan bermitra dengan DELCO, Anda dapat merasa tenang karena mengetahui bahwa Anda membuat pilihan yang bijak untuk kesuksesan jangka panjang perusahaan Anda.