Katup Kontrol Bermotor/Elektrik DELCO-ZDLP/ZDLM

Kemampuan operasi jarak jauh dari katup kontrol bermotor memungkinkan integrasi yang mulus ke dalam sistem kontrol otomatis, sehingga operator dapat memantau dan menyesuaikan pengaturan katup dari lokasi terpusat.

Katup penyesuaian dudukan tunggal elektrik (selongsong) berukuran kecil dan berkinerja sangat baik, serta merupakan produk katup kontrol elektrik tipe dasar berkualitas tinggi. Katup ini cocok untuk sistem kontrol proses produksi untuk kondisi proses media fluida umum. Katup dudukan tunggal memiliki karakteristik pengoperasian yang andal, kebocoran dudukan kecil, karakteristik aliran kasar, rentang penyetelan lebar, struktur kompak, dan jalur aliran halus. Rangkaian produk ini memiliki kinerja yang baik dan pengoperasian yang stabil, serta dapat memenuhi kebutuhan kontrol pengguna dalam berbagai aplikasi.

Model: Katup kontrol listrik

Kisaran Ukuran: 1/2” hingga 12”

Kisaran Tekanan: 1,6 hingga 6,4MPa

Bahan: WCB atau Baja Tahan Karat 304/316

Keterangan

Bermotor/Listrik Katup Kontrol adalah katup yang mengatur aliran fluida menggunakan aktuator listrik. Katup ini menggunakan gerakan putar atau linier dari aktuator listrik untuk mencapai kontrol yang tepat atas media fluida, sehingga memungkinkan pengoperasian jarak jauh. Banyak digunakan dalam sistem otomasi seperti HVAC dan kontrol proses industri, katup ini memiliki fitur-fitur seperti respons cepat dan akurasi tinggi, serta dapat beradaptasi dengan berbagai tekanan, suhu, dan kondisi aliran.

Biasanya terintegrasi dengan sistem kontrol, katup kontrol bermotor menawarkan pemantauan dan pengoperasian jarak jauh yang andal. Berperan penting dalam meningkatkan efisiensi sistem dan memastikan kontrol aliran yang presisi, katup kontrol bermotor merupakan komponen yang sangat diperlukan dalam aplikasi otomasi modern.

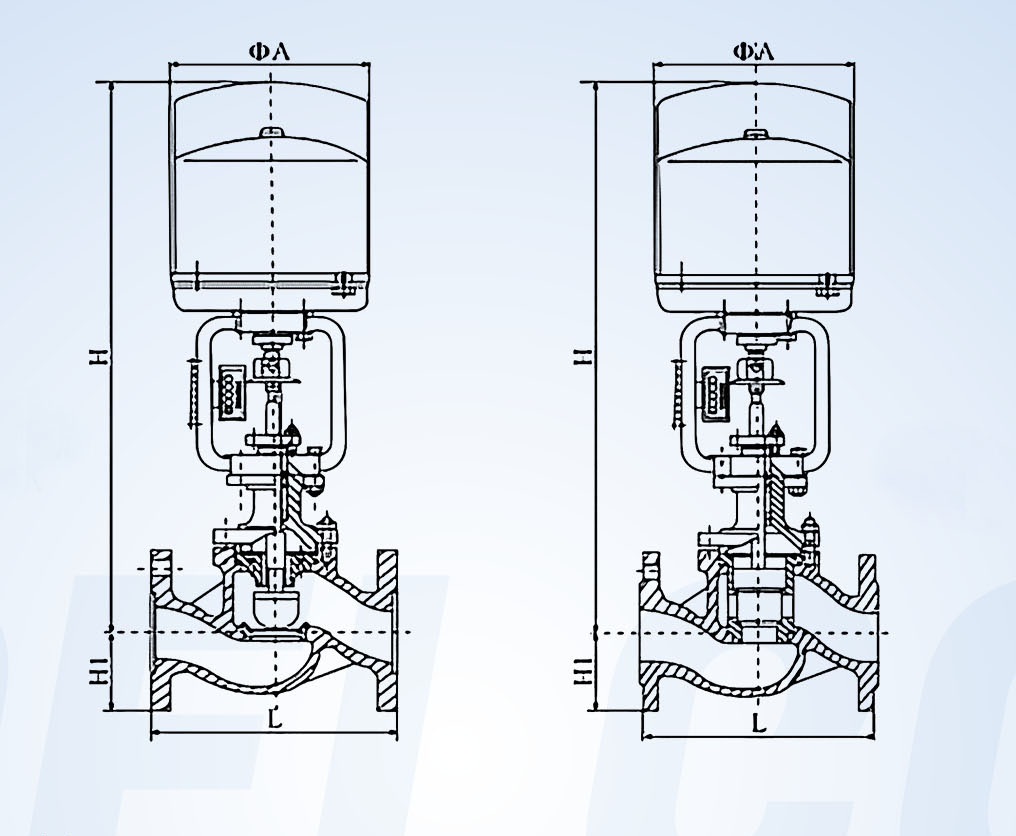

Produk ini terdiri dari aktuator listrik elektronik seri 3810L dan katup pengatur satu dudukan (selongsong) kecil. Aktuator memiliki struktur terintegrasi dengan modul pengontrol elektronik bawaan, sehingga tidak memerlukan penguat servo tambahan. Produk ini memiliki presisi tinggi dan mudah dipasang. Karakteristik katup selongsong adalah sebagai berikut:

Mengadopsi inti katup yang seimbang, gaya yang tidak seimbang menjadi kecil, perbedaan tekanan dibiarkan menjadi besar, dan operasinya stabil.

Permukaan pemandu kumparan yang besar meningkatkan osilasi yang disebabkan oleh arus eddy dan guncangan serta mengurangi kerusakan.

Kebisingan katup pengatur katup dudukan tunggal dan ganda biasa berkurang sekitar 10dB Struktur sederhana, perakitan dan pembongkaran mudah.

Tinjauan Umum Katup Kontrol Globe Aktuator Bermotor/Listrik:

| Jenis | Penggunaan | Catu daya | Sinyal kontrol | Aksi untuk menutup | Aksi untuk membuka |

| Aktuator bermotor/listrik, cerdas terintegrasi | mengatur | Tegangan 220 VAC ±10% 50Hz, Tegangan 380 VAC ±10% 50Hz | Tegangan DC 4-20mA, 1~5V DC | Sinyal input meningkat, batang katup turun, katup tertutup | Sinyal input meningkat, batang katup naik, katup terbuka |

| Ketinggalan | Tipe linier | Suhu operasi | Karakteristik aliran intrinsik | ||

| ≤0,8 %FS | ≤1 %FS | Tekanan Udara Bersih: -40℃~+250℃, -40℃~+450℃ | Baja Tahan Karat: -40℃~+250℃, -60℃~+450℃ | Garis lurus, persentase yang sama (rasio yang dapat disesuaikan secara inheren 50:1) | |

| Parameter teknis indikator katup kontrol bermotor/listrik | |||||

| Kesalahan dasar | Reaksi | Zona Mati | Kebocoran | Karakteristik aliran terukur | Karakteristik aliran intrinsik |

| ±1,0 % | 1% | 1% | Kapasitas katup 5*103 | ±10% | kemiringan ±30% |

| Parameter teknis katup kontrol indikator bermotor/listrik | |||||

| Kesalahan dasar | Reaksi | Zona Mati | Kebocoran | Karakteristik aliran terukur | Karakteristik aliran intrinsik |

| ±2,5 % | 1.50% | 3% | Kapasitas terukur katup 1*10^(-4) | ±10% | kemiringan ±30% |

Industri dan Aplikasi Katup Kontrol

Aplikasi katup kontrol mencakup berbagai industri, termasuk:

Minyak dan gas: Mengontrol laju aliran, tekanan, dan suhu dalam jaringan pipa, proses penyulingan, dan sistem injeksi kimia.

Pemrosesan kimia: Mengatur aliran cairan korosif, abrasif, atau suhu tinggi dalam reaksi dan proses kimia.

Pembangkit listrik: Memastikan kelancaran operasi pembangkit listrik dengan mengendalikan aliran uap, air, dan gas dalam boiler dan turbin.

Pengolahan air dan air limbah: Mengelola aliran dan tekanan di stasiun pompa, jaringan distribusi, dan proses pengolahan.

Perawatan Katup Kontrol

Periksa katup secara teratur, cari tanda-tanda keausan, kerusakan, atau kebocoran.

Jika ada bagian yang rusak atau aus, gantilah dengan pengganti berkualitas tinggi dari produsen.

Lumasi katup sesuai dengan petunjuk pabrik menggunakan jenis dan jumlah pelumas yang direkomendasikan.

Bersihkan katup dan komponen-komponennya secara teratur untuk menghilangkan kotoran, serpihan, dan kontaminan lain yang dapat memengaruhi kinerja atau merusak katup.

Uji katup secara berkala untuk memastikan katup beroperasi dengan baik dan sesuai spesifikasi.

Catat semua aktivitas pemeliharaan untuk referensi di masa mendatang dan kepatuhan terhadap peraturan industri.

Penting juga untuk memiliki personel terlatih untuk melakukan tugas pemasangan dan pemeliharaan ini guna memastikannya dilakukan dengan aman dan benar. Selain itu, petunjuk pemasangan dan pemeliharaan khusus dari produsen harus diikuti, karena berbagai jenis katup kontrol mungkin memiliki persyaratan yang unik. Dengan mengikuti petunjuk langkah demi langkah ini, Anda dapat memastikan bahwa katup kontrol Anda bekerja secara optimal dan memiliki masa pakai yang panjang.

Bisnis satu kali bukanlah tujuan kami, kami mengejar hubungan kemitraan jangka panjang.

Kami tidak hanya menyediakan penawaran harga sederhana tetapi ahli dalam pemilihan, perhitungan, dan penggambaran.

MINTA PENAWARAN

Produk Terkait

Menawarkan Solusi Katup Berorientasi Industri Untuk Anda

Perusahaan tidak hanya mengontrol kualitas secara langsung, tetapi juga tidak menoleransi masalah sebagai upaya mencapai kualitas tinggi. Pekerja harus menjalani pelatihan ketat dan penilaian ketat sebelum mereka dapat mulai bekerja.

Jaminan Kualitas

Perhitungan & Pemilihan, Kontrol Kualitas, Inspeksi, Layanan Purnajual, dll. Setiap Putaran Produksi untuk Memastikan Pelanggan Kami Tidak Memiliki Kekhawatiran.

Layanan

Di DELCO, kami percaya selalu ada solusi katup yang lebih baik untuk setiap pelanggan. Kami sangat bersemangat tentang hal itu, dan misi kami adalah memproduksi & memasok berbagai katup kontrol & regulator tekanan inovatif yang didukung oleh dukungan layanan global, sehingga menjamin tidak adanya cacat dalam waktu tunggu tersingkat.

Pasar Produksi

DELCO memiliki jangkauan yang luas, mengekspor ke lebih dari 46 negara. Jadi kami memiliki gambaran pasar yang lengkap. Selamat datang untuk menjadi mitra bisnis jangka panjang bersama kami. Katup kontrol yang andal dan regulator tekanan yang dioperasikan sendiriProdusen

Kehormatan Perusahaan

Katup DELCO memiliki sertifikasi CE, RoHS, FDA, Peralatan listrik antiledakan.

Selama lebih dari 20 tahun, DELCO Valves telah berkomitmen untuk menyediakan katup berkualitas tinggi kepada pelanggan kami.

DELCO selalu berfokus pada satu hal: kepuasan pelanggan 100%. Kami berupaya keras untuk terus meningkatkan semua aspek operasi harian kami. Misi kami, ditambah dengan lini produk yang diproduksi dengan standar kualitas tertinggi, terus menjadi hal yang membedakan kami dari pesaing. Di Powell, semua fasilitas kami telah tersertifikasi ISO 9001 “Global Quality”.

Sebagai produsen katup industri terkemuka, kami menawarkan berbagai macam produk. Lini produk kami meliputi: katup gerbang, katup periksa, katup globe, katup periksa, katup periksa pelat ganda, dan katup kupu-kupu berkinerja tinggi. Dengan lini produk multiputaran terlengkap dari produsen sumber tunggal, katup kami diproduksi dengan standar kualitas tertinggi menggunakan teknik manufaktur ultra-modern dan sumber material yang cermat.

Sebagai perusahaan katup dengan layanan lengkap, kami menawarkan berbagai macam produk serta layanan perbaikan dan lapangan. Keahlian kami dalam bidang katup tak tertandingi dan kami berharap dapat memenuhi kebutuhan katup Anda di masa mendatang!