Teori Teknologi: Teknis…Praktis… Solusi Industri Otomasi yang Menarik

Di DELCO, kami memahami pentingnya kepuasan pelanggan dan berusaha memenuhi kebutuhan unik setiap klien. Sebagai pemasok katup yang andal, kami berkomitmen untuk menyediakan layanan pelanggan yang sangat baik dan produk berkualitas tinggi untuk memastikan kinerja dan keawetan yang optimal. Dengan memilih DELCO sebagai pemasok udara kontrol tepercaya, Anda dapat memperoleh manfaat dari rakitan katup yang disesuaikan yang dirancang khusus untuk memenuhi kebutuhan Anda, meningkatkan efisiensi, dan mengurangi waktu henti.

Cara Memilih Katup Kontrol: Panduan Rinci

Saat memilih katup kontrol, banyak faktor yang perlu dipertimbangkan, termasuk karakteristik aliran katup, ukuran, tingkat kebisingan, potensi kavitasi atau kerusakan akibat percikan api, bahan badan katup dan komponen internal, ukuran dan jenis aktuator, serta karakteristik dinamisnya. Elemen-elemen ini secara kolektif memengaruhi kinerja dan keandalan katup, memastikannya memenuhi persyaratan khusus aplikasi.

Daftar isi

- 3.1 Katup Bola

- 3.2 Katup Kupu-Kupu

- 3.3 Katup Bola

- 3.4 Katup Gerbang

- 4.1 Aktuator Pneumatik

- 4.2 Aktuator Listrik

1. Memahami Fungsi Dasar Katup Kontrol

Langkah pertama dalam memilih katup kontrol adalah untuk memahami fungsi-fungsi fundamentalnya. Fungsi-fungsi ini biasanya meliputi:

- Kontrol Throttle dan Aliran: Katup harus mengatur laju aliran secara efektif untuk menjaga stabilitas proses.

- Resistensi Aliran Rendah: Katup tidak boleh menunjukkan turbulensi atau hambatan aliran saat terbuka penuh, membantu meminimalkan kehilangan tekanan kepala.

- Pembukaan dan Penutupan Cepat: Katup harus merespons dengan cepat dalam keadaan darurat untuk memastikan keamanan sistem.

- Penyegelan yang rapat: Katup harus mencegah kebocoran tekanan tinggi untuk melindungi sistem dan komponennya.

- Aliran searah: Katup harus mencegah aliran balik, menghindari potensi kerusakan pada sistem.

- Kontrol Tekanan: Katup harus terbuka secara otomatis pada tingkat tekanan yang telah ditetapkan untuk mencegah kerusakan peralatan.

2. Jenis Katup Berdasarkan Gerakan Kontrolnya

Katup kontrol dapat dikategorikan menjadi dua jenis utama berdasarkan gerakan kontrolnya: gerakan linier dan gerakan putar.

Katup Gerak Linier

Katup Linier (Katup Multi-putaran): Katup ini memiliki desain batang geser yang mendorong elemen penutup ke posisi terbuka atau tertutup, yang biasa terlihat pada katup bola dan katup gerbang. Jenis ini cocok untuk aplikasi yang memerlukan penyesuaian aliran yang tepat.

Katup Gerak Putar

Katup seperempat putaran: Katup ini dapat dibuka atau ditutup sepenuhnya dengan memutar batang katup 90 derajat. Jenis yang umum termasuk katup bola dan katup kupu-kupu. Katup ini beroperasi lebih cepat daripada katup gerak linier, sehingga ideal untuk aplikasi buka/tutup cepat dan aliran tinggi.

3. Jenis Katup Umum dan Aplikasinya

Aktuator merupakan komponen penting dari katup kontrol, dan jenisnya secara langsung memengaruhi kinerja katup. Aktuator dapat dikategorikan menjadi dua jenis utama: pneumatik dan elektrik.

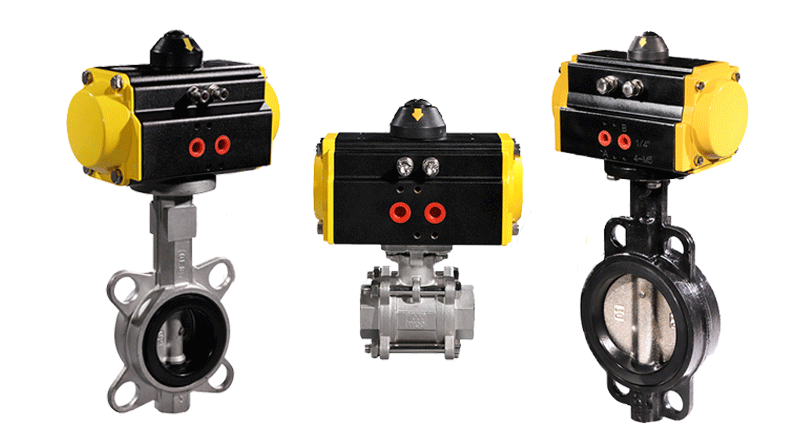

Katup Bola

katup bola adalah katup pembuka cepat yang memberikan segel rapat. Saat terbuka penuh, katup ini menghasilkan turbulensi atau hambatan aliran minimal. Katup ini secara luas dianggap sebagai katup pemulihan tinggi yang cocok untuk aplikasi cairan bersuhu tinggi.

- Terbaik untuk Kontrol: Pembukaan cepat, pengaturan linier.

- Penggunaan: Hidup/mati, pelambatan, cairan bersuhu tinggi.

- Keuntungan: Biaya rendah, kapasitas aliran tinggi, kebocoran rendah, pengoperasian seperempat putaran mudah.

- Kekurangan: Karakteristik pelambatan terbatas, rentan terhadap kavitasi.

Katup Kupu-Kupu

Katup kupu-kupu terdiri dari cakram yang terpasang pada poros yang dapat berputar untuk mengendalikan aliran. Katup ini dianggap sebagai katup pemulihan tinggi karena hanya cakram yang menghalangi jalur aliran. Katup ini cocok untuk pembatasan tanpa memerlukan segel yang rapat.

- Terbaik untuk Kontrol:Linear, persentase yang sama.

- Penggunaan: Layanan on/off atau pelambatan, operasi sering, aplikasi yang memerlukan penurunan tekanan rendah.

- Keuntungan: Biaya rendah, perawatan ringan, kontrol aliran baik.

- Kekurangan: Persyaratan torsi tinggi untuk kontrol, rentan terhadap kavitasi pada aliran rendah.

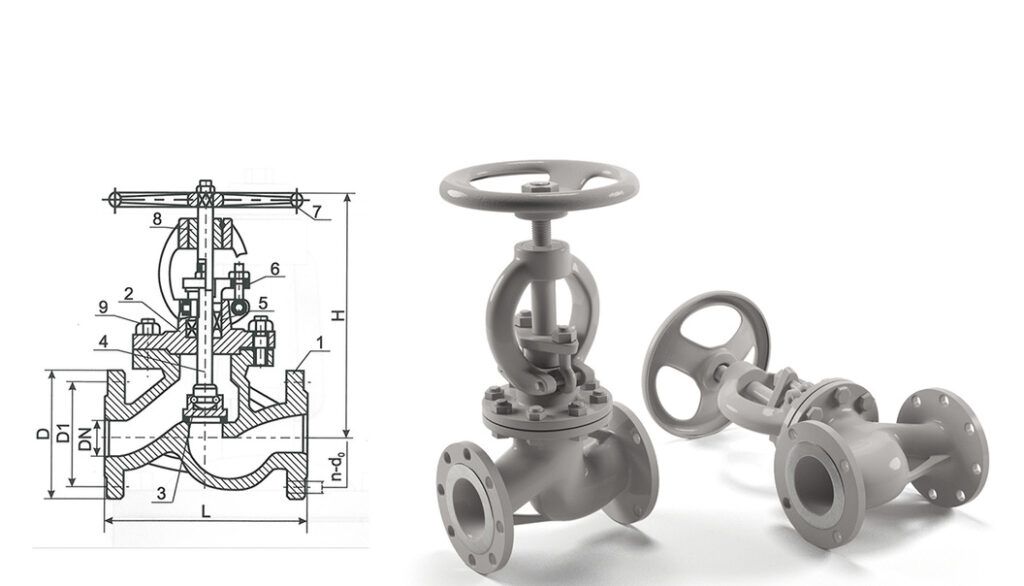

Katup Globe

Katup bola memiliki elemen cakram bergerak yang mengendalikan aliran melalui dudukan tetap di dalam badan bulat. Katup ini dapat diposisikan di mana saja antara terbuka penuh dan tertutup penuh untuk mengatur aliran. Katup ini cocok untuk aplikasi penurunan tekanan tinggi.

- Terbaik untuk Kontrol:Linear, persentase yang sama.

- Penggunaan: Pengaturan aliran yang tepat, operasi pembatasan yang sering.

- Keuntungan:Pengendalian aliran yang efisien dan tepat, kontrol aliran yang akurat.

- Kekurangan: Pemulihan rendah, koefisien aliran (Cv) relatif rendah, penurunan tekanan lebih tinggi, lebih mahal.

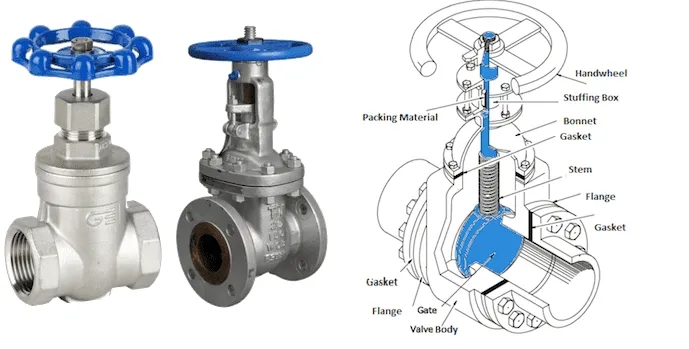

Katup Gerbang

katup gerbang menggunakan batang gerak linier untuk membuka dan menutup katup, menggunakan cakram paralel atau berbentuk baji untuk memberikan segel yang rapat. Ideal untuk membuka atau menutup dengan cepat dengan hambatan aliran minimal.

Terbaik untuk Kontrol: Pembukaan cepat.

Penggunaan: Sepenuhnya terbuka/tertutup, tanpa pembatasan, pengoperasian jarang.

Aplikasi: Cocok untuk minyak, gas, udara, cairan berat, uap, dan gas yang tidak terkondensasi.

Keuntungan:Kapasitas besar, penutupan rapat, biaya rendah.

Kekurangan: Kontrol buruk, potensi kavitasi pada penurunan tekanan rendah, tidak cocok untuk pelambatan.

4. Memilih Aktuator yang Tepat

Aktuator merupakan komponen penting dari katup kontrol, dan jenisnya secara langsung memengaruhi kinerja katup. Aktuator dapat dikategorikan menjadi dua jenis utama: pneumatik dan elektrik.

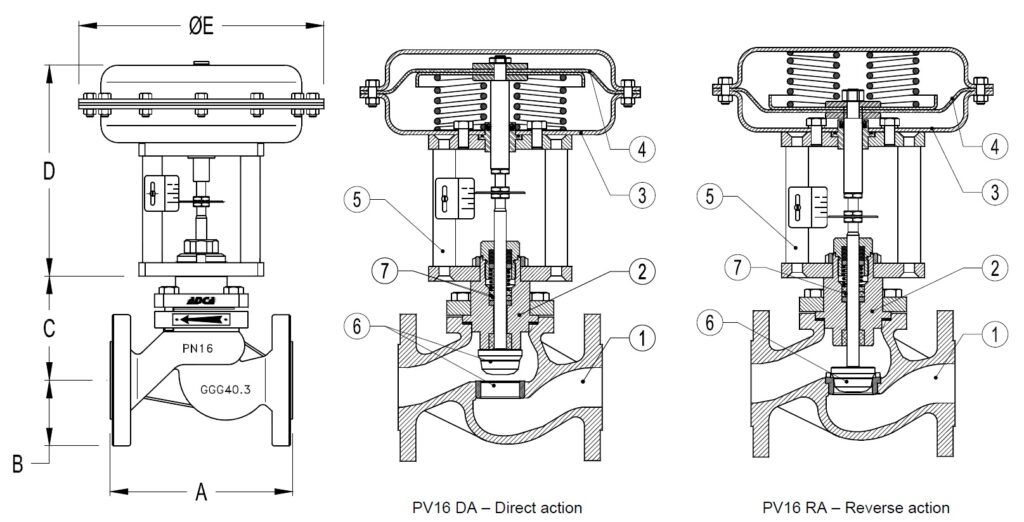

Aktuator Pneumatik

Aktuator pneumatik menggunakan sinyal udara dari perangkat kontrol eksternal untuk beroperasi, biasanya tersedia dalam aktuator piston dan aktuator diafragma.

- Aktuator Piston: Digunakan ketika aktuator diafragma tidak memiliki langkah atau daya dorong yang cukup.

- Aktuator Diafragma: Terapkan udara bertekanan ke membran fleksibel, beroperasi dalam konfigurasi kerja tunggal untuk respons cepat.

Aktuator Listrik

Aktuator listrik adalah perangkat penggerak motor yang memanfaatkan sinyal masukan listrik untuk menghasilkan gerakan rotasi, yang diubah menjadi gerakan linier untuk memodulasi variabel proses.

- Keuntungan: Biaya pengoperasian lebih rendah, waktu respons instan, kontrol presisi.

- Kekurangan: Jika terjadi pemadaman listrik, katup tetap berada di posisi terakhir kecuali sumber daya cadangan tersedia, yang biasanya lebih mahal daripada aktuator pneumatik.

5. Fitur Keamanan

Saat memilih aktuator, penting untuk mempertimbangkan fitur keselamatan, seperti:

Fungsi Gagal Tutup/Gagal Buka: Jika terjadi kegagalan udara (atau sinyal kontrol), katup akan menutup atau terbuka karena tekanan pegas.

Tindakan Kontrol pada Katup Pneumatik

- “Udara Terbuka”: Pembatasan aliran berkurang seiring meningkatnya nilai sinyal kontrol.

- “Tutup Udara”: Pembatasan aliran meningkat seiring dengan meningkatnya nilai sinyal kontrol.

6. Kesimpulan

Memilih katup kontrol yang tepat memerlukan penilaian menyeluruh terhadap kebutuhan aplikasi, karakteristik fluida, jenis katup, opsi aktuator, dan fitur keselamatan. Pengambilan keputusan yang tepat dapat meningkatkan efisiensi sistem, memastikan keselamatan, dan meningkatkan keandalan. Pemahaman mendalam tentang berbagai katup dan karakteristiknya akan membantu mengoptimalkan proses industri, mengurangi biaya pengoperasian, dan meningkatkan produktivitas secara keseluruhan.

Mengapa semakin banyak merek katup internasional memilih DELCO untuk layanan OEM?

Didirikan pada tahun 2011, Katup DELCO adalah pemimpin global di sektor industri. Produk utama kami meliputi katup aktuator elektrik, katup aktuator pneumatik, aktuator otomasi, dan katup solenoid. Selama hampir 20 tahun, kami telah memanfaatkan produk, keahlian teknik, dan solusi otomasi industri kami untuk memecahkan berbagai masalah proyek industri bagi pelanggan kami, termasuk proyek makanan, minuman, kimia, pengolahan air, farmasi, gas alam, minyak, dan HVAC. Saat ini kami memiliki lima anak perusahaan dan lebih dari 50 distributor di seluruh dunia yang menyediakan layanan respons cepat.

Semua produk DELCO menjalani proses desain, rekayasa, dan manufaktur internal 100% yang dipimpin oleh teknisi yang sangat terampil dan berpengalaman dengan menggunakan teknologi Italia dan Jerman untuk memproduksi katup, aktuator, dan solusi berkualitas tinggi, aman, andal, dan bernilai ekonomis. Standar manufaktur dapat dibuktikan dengan sertifikasi yang diperoleh selama bertahun-tahun.

Dan dengan sertifikasi Sistem Manajemen Mutu ISO 9001:2015 serta banyak sertifikasi lain seperti: SGS, RoHS, CNEX, TUV, CE, FDA. Sertifikasi ini membuktikan bahwa DELCO mematuhi standar kualitas dan keamanan tertinggi di seluruh dunia saat memproduksi produknya.

Bagaimana cara mendapatkan penawaran cepat untuk katup industri?

Jika Anda memiliki pertanyaan tentang katup atau ingin mendapatkan penawaran harga, jangan ragu untuk menghubungi kami, kami akan membalas dalam waktu 6 jam. Telepon +86 159 8960 2972, WhatsApp +86 159 8960 2972 atau email marketing [email protected].

Kualitas, harga yang kompetitif, dan layanan yang sangat baik dari DELCO menjadikannya mitra katup terbaik untuk membantu Anda mengembangkan bisnis. Sesuaikan katup Anda, kami tidak memiliki pesanan minimum.

Di DELCO, kami memahami pentingnya kepuasan pelanggan dan berusaha memenuhi kebutuhan unik setiap klien. Sebagai pemasok katup kontrol yang andal, kami berkomitmen untuk menyediakan layanan pelanggan yang sangat baik dan produk berkualitas tinggi untuk memastikan kinerja dan keawetan yang optimal. Dengan memilih DELCO sebagai pemasok katup kontrol tepercaya, Anda dapat memperoleh manfaat dari rakitan katup yang disesuaikan yang dirancang khusus untuk memenuhi kebutuhan Anda, meningkatkan efisiensi, dan mengurangi waktu henti.

Lebih jauh lagi, harga kompetitif kami pada regulator tekanan elektronik memungkinkan Anda menawarkan solusi terbaik. Sebagai salah satu produsen katup kontrol terkemuka, kami bangga dalam menyediakan katup andal yang tidak hanya memenuhi standar industri tetapi juga berkontribusi pada profitabilitas bisnis Anda secara keseluruhan. Dengan bermitra dengan DELCO, Anda dapat merasa tenang karena mengetahui bahwa Anda membuat pilihan yang bijak untuk kesuksesan jangka panjang perusahaan Anda.