Tech Theory: Technical…Practical… Interesting Automation Industrial Solutions

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control air supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

How to Choose Control Valves: A Detailed Guide

When selecting control valves, many factors need to be considered, including the valve’s flow characteristics, size, noise levels, potential for cavitation or flashing damage, materials of the valve body and internal components, the size and type of actuator, and its dynamic characteristics. These elements collectively impact the performance and reliability of the valve, ensuring it meets the specific requirements of the application.

Table of contents

- 3.1 Ball Valves

- 3.2 Butterfly Valves

- 3.3 Globe Valves

- 3.4 Gate Valves

- 4.1 Pneumatic Actuators

- 4.2 Electric Actuators

1. Understanding the Basic Functions of Control Valves

The first step in choosing a control valve is to understand its fundamental functions. These functions typically include:

- Throttle and Flow Control: The valve should effectively regulate the flow rate to maintain process stability.

- Low Flow Resistance: The valve should exhibit no turbulence or flow resistance when fully open, helping to minimize head pressure loss.

- Rapid Opening and Closing: The valve must respond quickly in emergencies to ensure system safety.

- Tight Sealing: The valve should prevent high-pressure leaks to protect the system and its components.

- Unidirectional Flow: The valve must prevent backflow, avoiding potential damage to the system.

- Pressure Control: The valve should automatically open at preset pressure levels to prevent equipment damage.

2. Types of Valves Based on Control Motion

Control valves can be categorized into two main types based on their control motion: linear motion and rotary motion.

Linear Motion Valves

Linear Valves (Multi-turn Valves): These feature a sliding rod design that pushes the closing element into the open or closed position, commonly seen in globe and gate valves. This type is suitable for applications requiring precise flow adjustment.

Rotary Motion Valves

Quarter-turn Valves: These valves achieve full opening or closing by rotating the valve stem 90 degrees. Common types include ball valves and butterfly valves. They operate faster than linear motion valves, making them ideal for quick open/close and high-flow applications.

3. Common Valve Types and Their Applications

The actuator is a crucial component of the control valve, and its type directly influences the valve’s performance. Actuators can be categorized into two main types: pneumatic and electric.

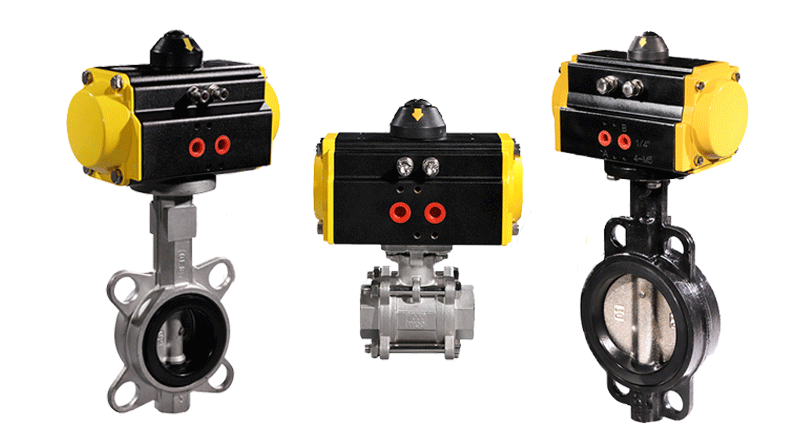

Ball Valves

Ball valves are quick-opening valves that provide a tight seal. When fully open, they produce minimal turbulence or flow resistance. They are widely regarded as high-recovery valves suitable for high-temperature fluid applications.

- Best for Control: Quick opening, linear regulation.

- Uses: On/off, throttling, high-temperature fluids.

- Advantages: Low cost, high flow capacity, low leakage, easy quarter-turn operation.

- Disadvantages: Limited throttling characteristics, prone to cavitation.

Butterfly Valves

Butterfly valves consist of a disc attached to a shaft that can rotate to control flow. They are considered high-recovery valves because only the disc obstructs the flow path. They are suitable for throttling without requiring a tight seal.

- Best for Control: Linear, equal percentage.

- Uses: On/off or throttling services, frequent operation, applications needing low pressure drop.

- Advantages: Low cost, lightweight maintenance, good flow control.

- Disadvantages: High torque requirements for control, prone to cavitation at low flows.

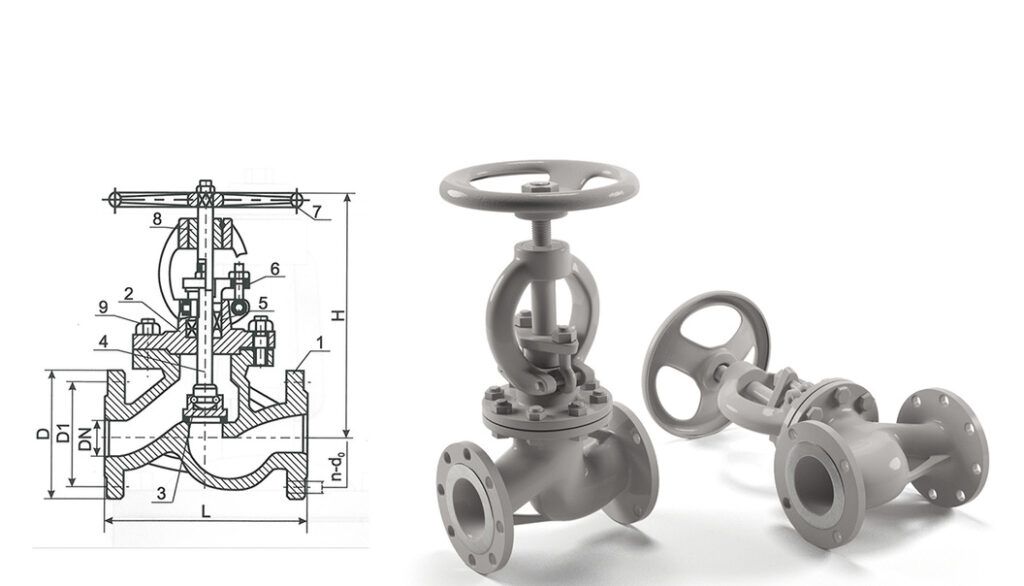

Globe Valves

Globe valves feature a movable disc element that controls flow through a fixed seat within a spherical body. They can be positioned anywhere between fully open and fully closed to regulate flow. These valves are suitable for high-pressure drop applications.

- Best for Control: Linear, equal percentage.

- Uses: Precise flow regulation, frequent throttling operations.

- Advantages: Efficient and precise throttling, accurate flow control.

- Disadvantages: Low recovery, relatively low flow coefficient (Cv), higher pressure drop, more expensive.

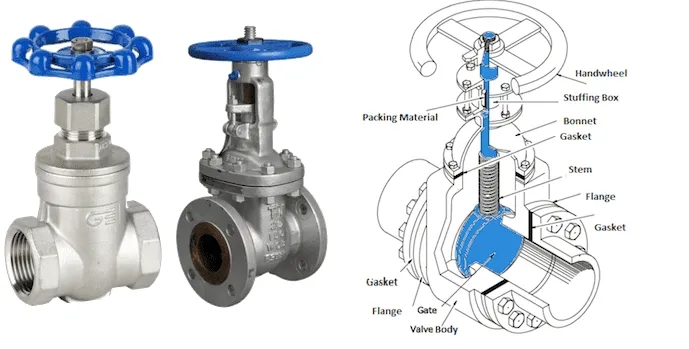

Gate Valves

Gate valves use a linear motion stem to open and close the valve, employing parallel or wedge-shaped discs to provide a tight seal. They are ideal for quick opening or closing with minimal flow resistance.

Best for Control: Quick opening.

Uses: Fully open/closed, no throttling, infrequent operation.

Applications: Suitable for oil, gas, air, heavy liquids, steam, and non-condensable gases.

Advantages: Large capacity, tight shut-off, low cost.

Disadvantages: Poor control, potential cavitation at low pressure drops, not suitable for throttling.

4. Choosing the Right Actuator

The actuator is a crucial component of the control valve, and its type directly influences the valve’s performance. Actuators can be categorized into two main types: pneumatic and electric.

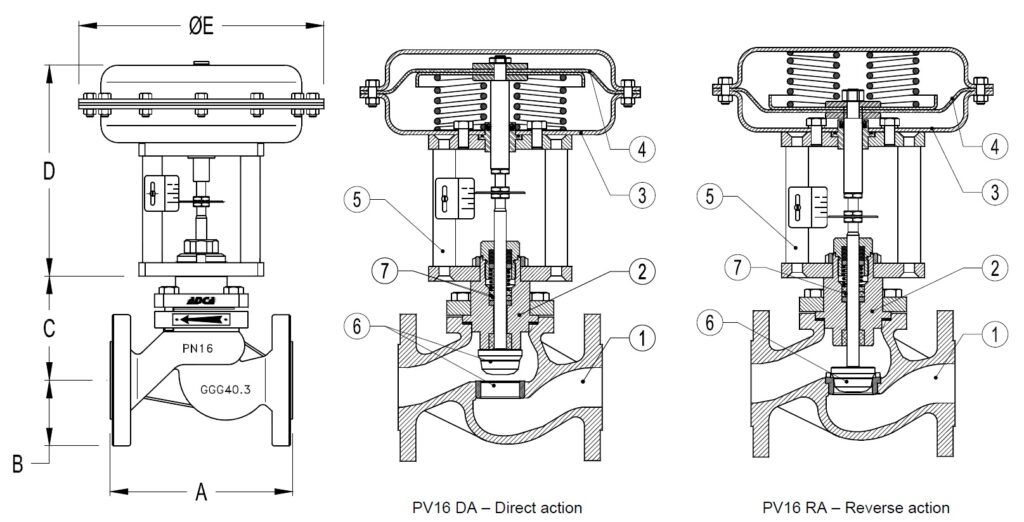

Pneumatic Actuators

Pneumatic actuators use air signals from external control devices to operate, typically available in piston actuators and diaphragm actuators.

- Piston Actuators: Used where diaphragm actuators have insufficient stroke or thrust.

- Diaphragm Actuators: Apply compressed air to a flexible membrane, operating in single-acting configurations for quick response.

Electric Actuators

Electric actuators are motor-driven devices that utilize electrical input signals to generate rotational motion, which is converted to linear motion to modulate process variables.

- Advantages: Lower operating costs, instant response times, precise control.

- Disadvantages: In the event of a power outage, the valve remains in the last position unless a backup power source is available, typically more expensive than pneumatic actuators.

5. Safety Features

When selecting actuators, it’s essential to consider safety features, such as:

Fail Close/Fail Open Functions: In the event of air (or control signal) failure, the valve will close or open under spring pressure.

Control Actions in Pneumatic Valves

- “Air Open”: Flow restriction decreases as control signal values increase.

- “Air Close”: Flow restriction increases as control signal values increase.

6. Conclusion

Choosing the right control valve requires a comprehensive assessment of application needs, fluid characteristics, valve types, actuator options, and safety features. Making informed decisions can enhance system efficiency, ensure safety, and improve reliability. A deep understanding of various valves and their characteristics will aid in optimizing industrial processes, reducing operating costs, and increasing overall productivity.

Why more and more international valve brands choose DELCO for OEM service?

Founded in 2011, DELCO Valve is a global leader in the industrial sector. Our main products include electric actuator valves, pneumatic actuator valves, automation actuators and solenoid valves. For nearly 20 years, we have utilized our products, engineering expertise and industrial automation solutions to solve countless industrial project problems for our customers, including food, beverage, chemical, water treatment, pharmaceutical, natural gas, oil and HVAC projects. We currently have five subsidiaries and more than 50 distributors around the world providing rapid response service.

All DELCO products undergo a 100% in-house design, engineering and manufacturing process led by highly skilled and experienced engineers using Italian and German technology to manufacture high quality, safe, reliable and value for money valves, actuators and solutions. Manufacturing standards can be demonstrated by the certifications obtained over the years.

And with the ISO 9001:2015 Quality Management System certification as well as many other certifications such as: SGS, RoHS, CNEX, TUV, CE, FDA. these certifications prove that DELCO adheres to the highest quality and safety standards worldwide when manufacturing its products.

How to get a quick quote for industrial valves?

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email marketing [email protected].

DELCO’s quality, competitive prices and excellent service make it the best valve partner to help you grow your business. Customize your valves, we have no minimum order.

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.