Tech Theory: Technical…Practical… Interesting Automation Industrial Solutions

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control air supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Globe Valves Installation and Applications Guide

Part 1: Understanding Globe Valves

What Is A Globe Valve?

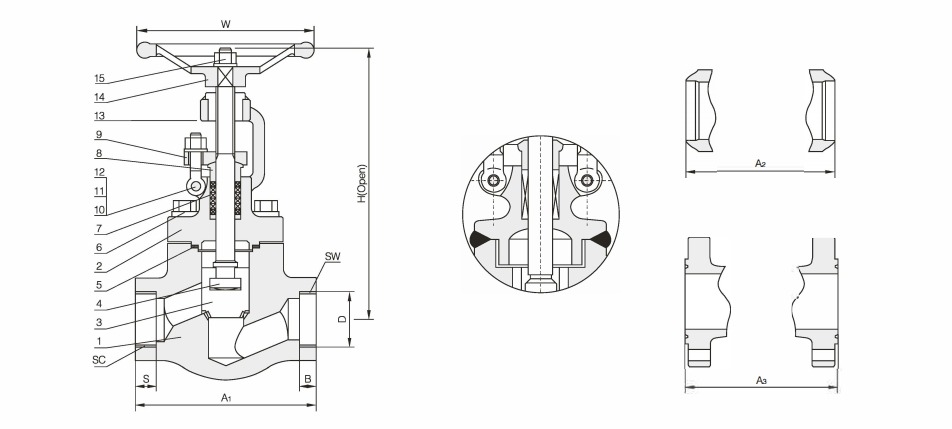

A globe valve is a linear motion valve designed to stop, start, and regulate fluid flow. It features a spherical body containing an internal baffle that houses a movable disk or plug which seals against a stationary seat.

How Does A Globe Valve Work?

A globe valve operates through the upward and downward movement of the valve stem. When the handwheel is turned, the stem moves the disc or plug toward or away from the seat, which is perpendicular to the flow path, thereby controlling the fluid flow through the valve.

What Is The Purpose Of A Globe Valve?

The primary purpose of a globe valve is to regulate flow in a pipeline. It is specifically designed to throttle flow and can also completely shut off the fluid flow when needed.

What Does A Globe Valve Do?

A globe valve controls flow in a pipeline by adjusting the distance between a movable disk and a stationary ring seat, thereby throttling the flow as required.

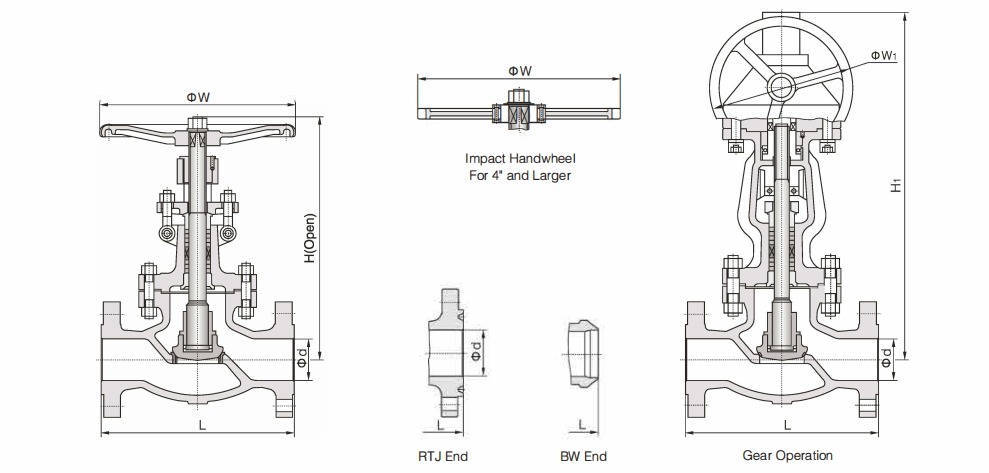

What Does A Globe Valve Look Like?

A globe valve typically has a spherical body with a protruding bonnet on top, which houses the stem and handwheel. Internally, it has a baffle that splits the body, with the seat on one side and the disk or plug on the other.

Part 2: Installation Queries

Are Globe Valves Directional?

Yes, globe valves are directional due to their design and must be installed with the flow direction in mind to function correctly.

Can A Globe Valve Be Installed Vertically?

Yes, a globe valve can be installed vertically as long as the flow direction is maintained and the valve is adequately supported.

Why Is A Globe Valve Unidirectional?

A globe valve is considered unidirectional because it is designed to function with the flow in one direction, ensuring proper operation and effective shut-off.

Can A Globe Valve Be Installed On Its Side?

Yes, a globe valve can be installed on its side, but the flow direction must be adhered to as per the manufacturer’s instructions, and the actuator must remain accessible.

Can A Globe Valve Have No Friction?

No mechanical valve can be entirely frictionless. There will always be some resistance when moving parts against each other, particularly the disk against the valve seat. However, well-designed valves can minimize friction.

Part 3: Differentiation of Globe Valve with Other Valves

How To Identify Gate And Globe Valve?

Gate valves have a flat gate that slides vertically in and out of the flow, while globe valves have a movable disk that moves perpendicular to the flow. Globe valves typically have a round body, and their stem movement is usually guided by a bonnet outside the valve body. Gate valves have a rising or non-rising stem that moves up or down as the valve is operated.

What Is The Difference Between A Gate Valve And A Globe Valve?

The main difference lies in their design and functionality: gate valves are optimized for on/off control, featuring a gate that moves up or down to block flow, while globe valves are used for throttling, with a disk that moves in or out of the seat to regulate flow.

How To Tell A Globe Valve From A Gate Valve?

A globe valve typically has a spherical body with the valve stem at the top operating perpendicular to the flow, while a gate valve has a more elongated body with a gate that moves up and down parallel to the flow.

What’s The Difference Between Shutoff Valves: Ball, Gate, And Globe?

- Ball Valves: Provide tight shut-off and are used for on-off service with low pressure drop.

- Gate Valves: Designed for on-off service, featuring a gate that moves up and down in the flow path and are used where straight-line flow with minimum restriction is required.

- Globe Valves: Used for throttling service, offering precise flow control.

Part 4: Globe Valves in the Field

Why Is A Globe Valve Used In A Steam Line?

Globe valves are used in steam lines because they can precisely control the flow and pressure of the steam, which is critical for the efficiency and safety of steam systems.

Where Are Globe Valves Used?

Globe valves are used in various applications, including water, steam, and gas systems, where flow needs to be regulated or completely stopped.

A Globe Valve Is Best Suited For:

Applications that require flow regulation, throttling, and frequent operation. It is also used where pressure drop through the valve is not a critical concern.

Can You Control Steam Pressure With Globe Valves?

Yes, steam pressure can be controlled with globe valves by adjusting the valve opening, which regulates the flow and consequently the pressure.

Can You Use Hunter PGV Globe Valves On A Golf Course?

Hunter PGV globe valves are typically used in irrigation systems and may be suitable for use on golf courses, depending on the specific requirements of the irrigation system.

Do Gas Cylinders Have Gate Or Globe Valves?

Gas cylinders can have different types of valves, including gate or globe valves, depending on their intended use and the system requirements.

Do Globe Valves Restrict Flow Hot Water?

When fully open, globe valves do not significantly restrict flow, but they do have a higher pressure drop compared to other valves like ball or gate valves. When partially open, they effectively restrict and regulate the flow of hot water.

Do You Use Globe Valves On A Steam System?

Yes, globe valves are commonly used on steam systems for their ability to throttle and precisely control the flow of steam.

When To Use A Globe Valve?

A globe valve should be used when you need to regulate or throttle the flow, or when you require frequent operation of the valve.

When To Use A Globe Valve In Steam?

Use a globe valve in a steam system when you need to control the steam flow rate or maintain and reduce steam pressure.

Where To Place Globe Valve On An Irrigation System?

Place a globe valve at strategic points where flow control is needed, such as at the start of a zone, to regulate or stop flow for maintenance, or to control the flow to different sections of the system.

Where We Use Globe Valve?

Globe valves are used in applications that require flow regulation, such as cooling systems, fuel oil systems, feedwater, chemical feed, and steam services.

How to get a quick quote for industrial valves?

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email marketing [email protected].

DELCO’s quality, competitive prices and excellent service make it the best valve partner to help you grow your business. Customize your valves, we have no minimum order.

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.