Tech Theory: Technical…Practical… Interesting Automation Industrial Solutions

At DELCO Valve, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control air supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Explosion-Proof Electric Valves: Ensuring Industrial Safety

Catalog

1 . Introduction

2 . Understanding the Basics of Explosion-Proof Electric Valves

3 . Understanding the Basics of Explosion-Proof Electric Valves

4. Key Considerations for Selecting Suitable Explosion-Proof Electric Valves

4.1 Environmental Conditions

4.2 Certifications and Standards

4.3 Manufacturer Reputation

5. Key Considerations for Selecting Suitable Explosion-Proof Electric Valves

5.1 Installation Location

5.2 Electrical Connections

5.3 Operating Procedures

5. Maintenance and Care Techniques for Long-Term Performance

5.1 Routine Inspection

5.2 Cleaning and Lubrication

5.3 Avoid Overloading

6. Conclusion

7.How to quickly get a quote for industrial valves?

Introduction

In industrial environments, safety is paramount, and explosion-proof electric valves are critical components for maintaining it. This article aims to equip readers with comprehensive knowledge, practical selection criteria, and effective usage and maintenance techniques for explosion-proof electric valves, empowering them to make informed decisions and uphold safety standards in industrial operations.

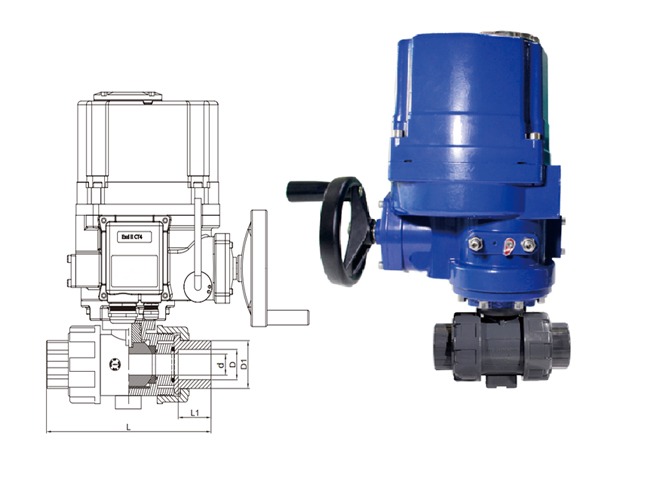

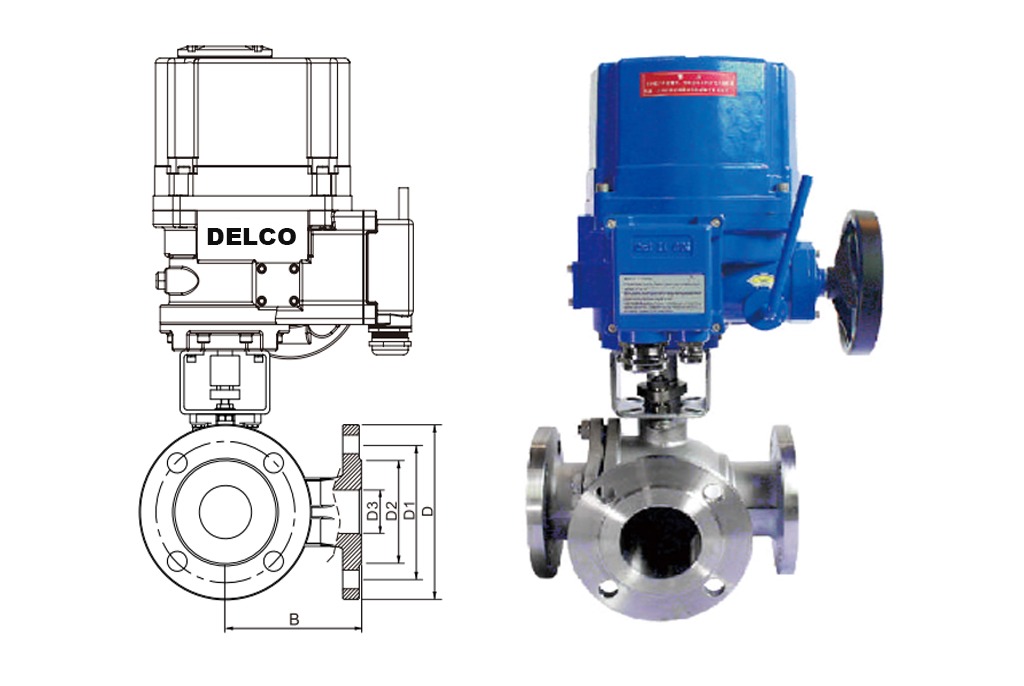

Understanding the Basics of Explosion-Proof Electric Valves

Explosion-proof electric valves are sophisticated devices designed to regulate fluid flow within industrial pipelines. They employ electric actuators to precisely control the opening and closing of valves, facilitating the management of flow rates, pressures, and other critical parameters. By converting electrical energy into mechanical motion, these valves automate processes, enhancing efficiency while minimizing safety risks associated with manual operation.

Key Considerations for Selecting Suitable Explosion-Proof Electric Valves

When selecting explosion-proof electric valves, several crucial factors must be taken into account:

Environmental Conditions: Assess the operating environment’s temperature, pressure, and the nature of the fluid being controlled to determine the appropriate valve specifications.

Certifications and Standards: Ensure that selected valves comply with industry-specific safety certifications and standards, such as ATEX and IECEx, to guarantee their suitability for hazardous locations.

Manufacturer Reputation: Choose valves from reputable manufacturers with a proven track record of producing high-quality, reliable products and providing excellent customer support.

Installation and Usage Guidelines for Explosion-Proof Electric Valves

Proper installation and usage are essential for maximizing the effectiveness and safety of explosion-proof electric valves:

Installation Location: Install valves in designated safe areas, away from potential sources of ignition or flammable materials, to minimize the risk of explosion.

Electrical Connections: Follow manufacturer guidelines for electrical wiring and connections, ensuring compliance with safety standards and codes to prevent electrical hazards.

Operating Procedures: Familiarize yourself with the recommended operating procedures outlined in the valve’s user manual, and strictly adhere to them to prevent accidents or damage due to improper operation.

Maintenance and Care Techniques for Long-Term Performance

Regular maintenance is crucial for ensuring the continued performance and safety of explosion-proof electric valves:

Routine Inspection: Schedule regular inspections to check valve integrity, electrical connections, and overall condition, addressing any issues promptly to prevent failures or malfunctions.

Cleaning and Lubrication: Keep valves clean and adequately lubricated to preserve their functionality and prevent corrosion or degradation over time.

Avoid Overloading: Avoid subjecting valves to prolonged periods of excessive stress or overloading, as this can lead to premature wear and failure, compromising safety and performance.

Conclusion

Explosion-proof electric valves are indispensable components in industrial settings, playing a pivotal role in maintaining safety and efficiency. By understanding their fundamental principles, adhering to proper selection criteria, and implementing effective usage and maintenance practices, readers can leverage these essential devices to safeguard industrial processes and uphold safety standards effectively.

How to get a quick quote for industrial valves?

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email marketing sales@delcofluid.com.

DELCO’s quality, competitive prices and excellent service make it the best valve partner to help you grow your business. Customize your valves, we have no minimum order.

At DELCO Valve, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.