Water Purification Project

Industrial Valves Used For Water Purification Project

Water purification is a critical process in ensuring the availability of clean and safe water for various uses, including drinking, industrial processes, and irrigation. This process involves the removal of undesirable chemicals, biological contaminants, suspended solids, and gases from water. The goal is to produce water that is fit for specific purposes.

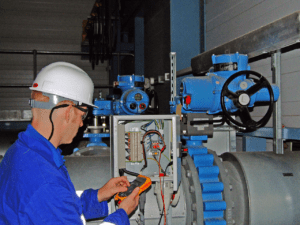

Industrial valves play a crucial role in the water purification process, offering precise control, reliability, and efficiency in managing the flow and treatment of water.

The Role of Industrial Valves in Water Purification:

1. Control and Regulation: Industrial valves control the flow of water and treatment chemicals throughout the purification process. They regulate the rate of flow and maintain the correct pressure levels within the system, ensuring that each phase of the purification process occurs under optimal conditions.

2. Isolation and Safety: Valves provide isolation for maintenance, emergency shutoff, and system integrity. They can isolate sections of the purification plant for maintenance or in response to a system failure, preventing contamination and ensuring the safety of the water supply.

3. Precision in Chemical Treatment: In the stages of water purification that require chemical treatment, such as disinfection or pH adjustment, valves ensure the precise dosing of chemicals. This precision is crucial for effective treatment and for maintaining the balance of chemical concentrations to avoid over or under-treatment.

4. Backflow Prevention: Certain types of industrial valves, such as check valves, prevent backflow, ensuring that purified water does not mix with untreated water or chemicals, thus maintaining the integrity of the purified water.

5. Durability and Reliability: Valves used in water purification must withstand corrosive substances and varying pressures and temperatures. Materials like stainless steel, PVC, and other corrosion-resistant materials are commonly used to enhance durability and reliability.

DELCO Solutions

Solutions Provided by Industrial Valves for Water Purification:

1. Control and Regulation: Industrial valves control the flow of water and treatment chemicals throughout the purification process. They regulate the rate of flow and maintain the correct pressure levels within the system, ensuring that each phase of the purification process occurs under optimal conditions.

2. Isolation and Safety: Valves provide isolation for maintenance, emergency shutoff, and system integrity. They can isolate sections of the purification plant for maintenance or in response to a system failure, preventing contamination and ensuring the safety of the water supply.

3. Precision in Chemical Treatment: In the stages of water purification that require chemical treatment, such as disinfection or pH adjustment, valves ensure the precise dosing of chemicals. This precision is crucial for effective treatment and for maintaining the balance of chemical concentrations to avoid over or under-treatment.

4. Backflow Prevention: Certain types of industrial valves, such as check valves, prevent backflow, ensuring that purified water does not mix with untreated water or chemicals, thus maintaining the integrity of the purified water.

5. Durability and Reliability: Valves used in water purification must withstand corrosive substances and varying pressures and temperatures. Materials like stainless steel, PVC, and other corrosion-resistant materials are commonly used to enhance durability and reliability.

Related Products

- Butterfly Valve

- Piston Valve

- Knife Gate Valve

- Automatic Air Valve

- Plug Valve

- Check Valve

- Gate Valve