Tech Theory: Technical…Practical… Interesting Automation Industrial Solutions

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control air supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

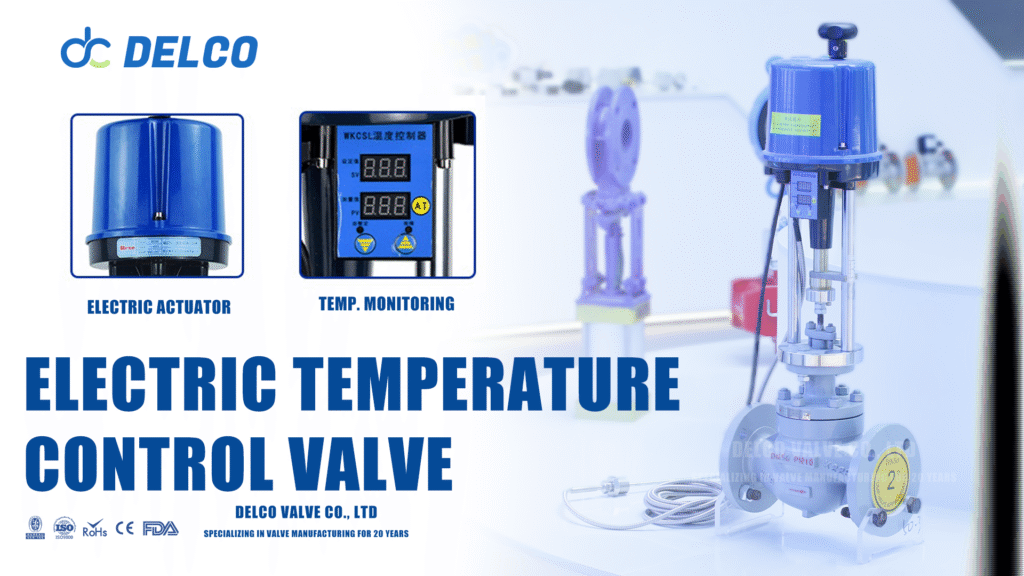

Electric Temperature Control Valve: Principle and Application Explanation

Electric Temperature Control Valve has the function of high-precision temperature regulation, which is widely used in industry, building HVAC and food processing and other fields. In this article, DELCO Valve will analyze its working principle, application scenarios and purchase points.

What is Electric Temperature Control Valve?

Electric Temperature Control Valve is a kind of equipment to control the fluid temperature by adjusting the valve opening degree through electric actuator. Its core function is to receive the temperature sensor signal, according to the set value of the automatic adjustment of fluid flow or mixing ratio, to achieve precise control of the system temperature.

Working Principle

The working principle of electric temperature control adjustment valve is mainly based on temperature and pressure changes. It controls the fluid flow and temperature by automatically adjusting the valve opening. Its main components include actuator, valve seat, valve and sensor.

Application Scenarios

- Industrial: In steam heating or cooling water systems for precise temperature control and improved productivity.

- HVAC: To optimize energy use in heating and cooling systems by regulating water flow or airflow.

- Food Processing: Heating or cooling temperature-sensitive liquids (e.g. dairy products, fruit juices) to ensure processing quality.

Selection Guide

- Determine temperature control range and precision: Select the appropriate temperature range and regulation precision according to system requirements.

- Consider material compatibility: Stainless steel is suitable for high temperature or corrosive liquids, cast iron is suitable for routine applications.

- Ensure signal compatibility: Ensure that the valve can receive the system’s control signals.

Installation and Maintenance Recommendations

- Installation requirements: Ensure that the temperature sensor is installed in the most sensitive location of the fluid to avoid inaccurate temperature measurement.

- Regular maintenance: Clean the valve body and sensor surface to avoid dirt affecting the measurement accuracy.

- Check the actuator: Check the status of the electric actuator periodically to prevent regulation failure due to stalling.

Contact DELCO For Quick Quote

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email [email protected].

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.