- Home

- ABOUT

ABOUT DELCO

Rich Experience In Valve Projects | Providing One-Stop Solutions

-----------------------------------------------------------------------------------------------------

ABOUT DELCO

DELCO VALVE CO.,LTD is a professional manufacturer of valves with more than 20+ years experience, we believe that there is always a better valve solution for every customer. We are deeply passionate about this belief, and our mission is to manufacture and supply a range of innovative control valves and pressure regulators, backed by global service support, to ensure zero defects within the shortest lead time.

Our primary focus lies in control valves, pneumatic valves, and motorized valves, among other valve products. Our control valves enable precise flow control and pressure regulation, making them suitable for a wide range of industries such as petrochemical, power, pharmaceutical, and food processing. If you have any questions related to valves or projects, please feel free to contact our technical team by [email protected], we will provide you with professional One-On-One service!

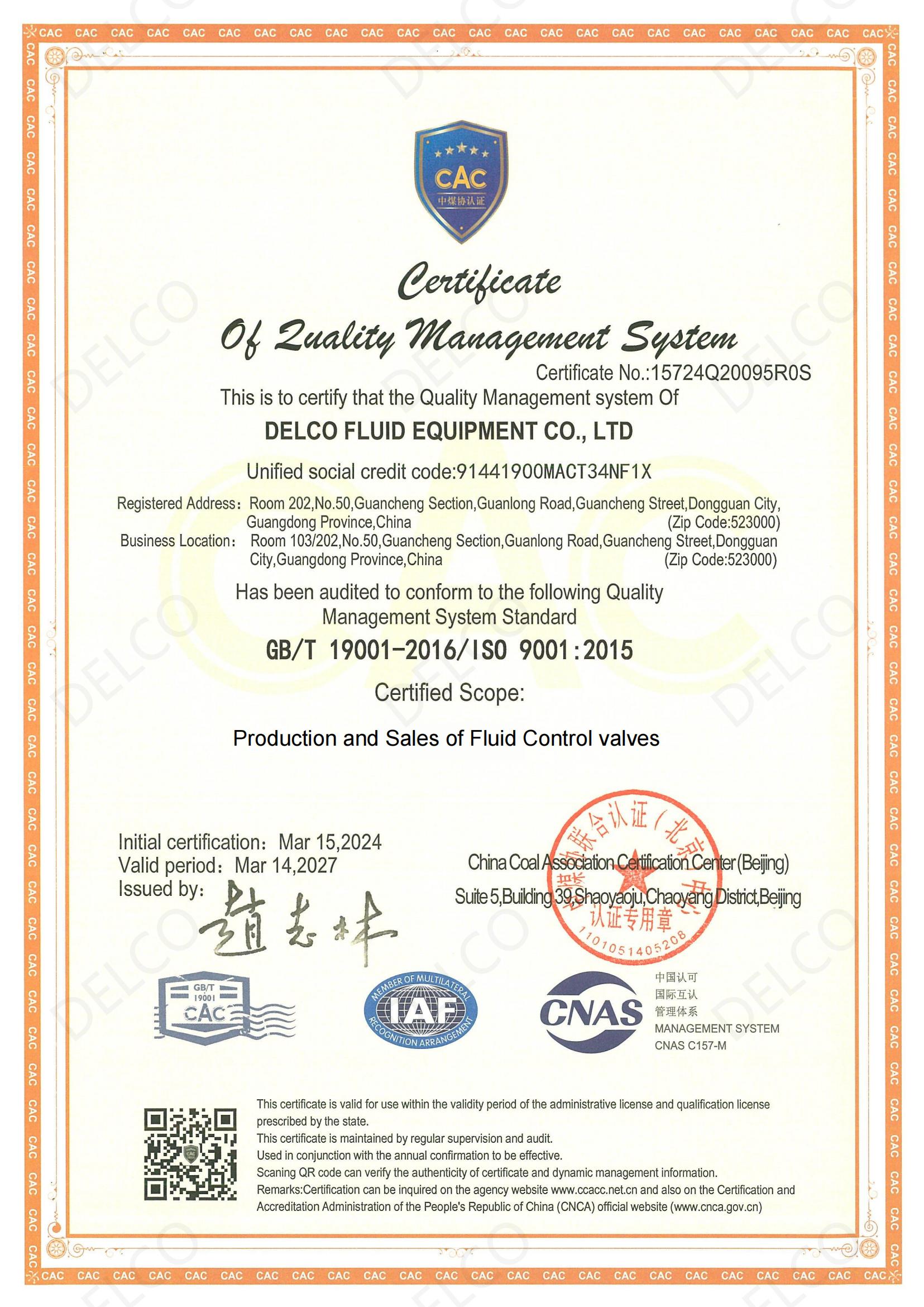

Choose no superiority, quality character, sincerity, and trust, multiple ROHS certifications, for your eco-friendly assurance.

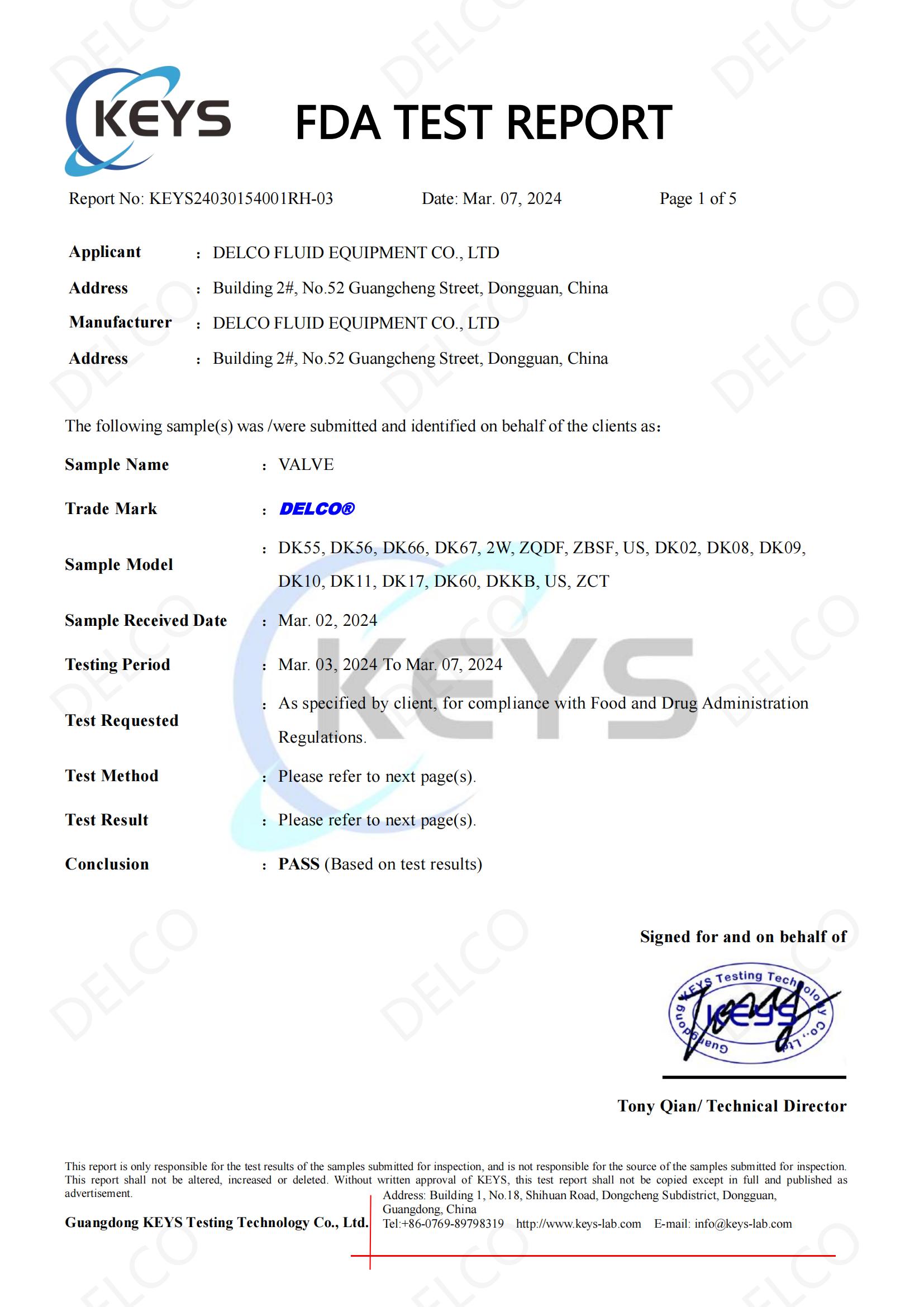

Choose no superiority, quality character, sincerity, and trust, numerous FDA certifications, for your peace of mind.

Choose no superiority, quality see character, sincerity and trust, multiple ISO certifications, for your assurance.

Choose no superiority, quality see character, sincerity and trust, anumber of CE certification, for your

escort.

ADVANTAGE

DELCO strives to become a leader in the valve industry, offering customers the best valve solutions. We adhere to the principles of putting quality first and prioritizing customer satisfaction, consistently innovating and pushing boundaries to create greater value for our customers.

ADVANTAGE

Four Factors For DELCO Sustainable Development

Our pneumatic valves are equipped with pneumatic actuators, which use air power to open and close the valves. They are known for their quick response and high reliability. These valves are widely used in automation systems and process control fields.

In addition, our electric valves utilize electric actuators to control the valve opening and closing through electrical signals. These valves offer precise control capabilities and automation features, making them highly valuable in remote control situations.

We are very careful about the details and quality of each control valve. We ensure that our products meet the EU market standard.

DETAILS AND QUALITY

We are very careful about the details and quality of each control valve. We ensure that our products meet the EU market standard.

DETAILS AND QUALITY

We’re not just quick to provide a commercial offer, datasheet, and drawings for bidding projects, but we also respond quickly to any product calibration issues and after-service on-site.

QUICK RESPONSE

Even if you just order 1one unit control valve, we all treat it very serious,seriously. The LOGO, NDT, ITP, inspection report, photos, everything customers’ needs we will try do our best to meet them.

OEM SERVICE

We offer unique, cost-effective valve solutions to meet your requirements. Just contact us anytime.

Testing and Quality Control

DELCO always put quality as the first consideration. All DELCO fluid control valves are designed, engineered and manufactured by experienced industry engineers to provide safe, reliable, dependable and affordable valves, actuators and solutions.

PRESSURE & FUNCTIONAL TESTING

The following tests can be performed according to API 6D, API 6DSS, API 598, EN12266-1, or to customer-specific requirements.

- Hydrostatic Testing

- Low-Pressure Air Seat Testing

- High-Pressure Air Testing

- Cryogenic Gas Testing (-196°C/-320,8°F)

- High-Temperature Testing (660°C/1220°F)

- Antistatic Testing

- Torque Testing

NON-DESTRUCTIVE TESTING (NDT)

The following tests can be performed by II level qualified personnel in accordance with EN473-ISO9712 / SNT-TC-1A.

- VT (Visual Testing)

- UT (Ultrasonic Testing)

- PT (Penetrant Testing)

- MT (Magnetic Particle Testing)

- PMI (Positive Material Identification)

- Hardness Test

- Ferrite Test

MATERIAL DESTRUCTIVE TESTING

Strong cooperation with Chemical Laboratories the following tests can be performed according to Customer’s and project specification requirements

- Mechanical & Impact test down to –196°C

- Chemical analysis check

- Corrosion tests

- Micro examinations

- Ferrite check

- Hydrogen-Inducted Cracking test (HIC)

- Hydrogen-Inducted Cracking test (HIC)

Our Certificates

Simply show our certificate, please contact us if you need special requirements

FAQ

Check our overseas customers’ frequently asked questions.

When can I get the price?

How can I get a sample to check your quality?

How long can I expect to get the sample?

How long does the whole procedure being worked out?

What about the transportation and delivery date?

Do you offer discounted products?

FEATURE PROJECTS

DELCO is able to customize a wide range of valve design standards