Tech Theory: Technical…Practical… Interesting Automation Industrial Solutions

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control air supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

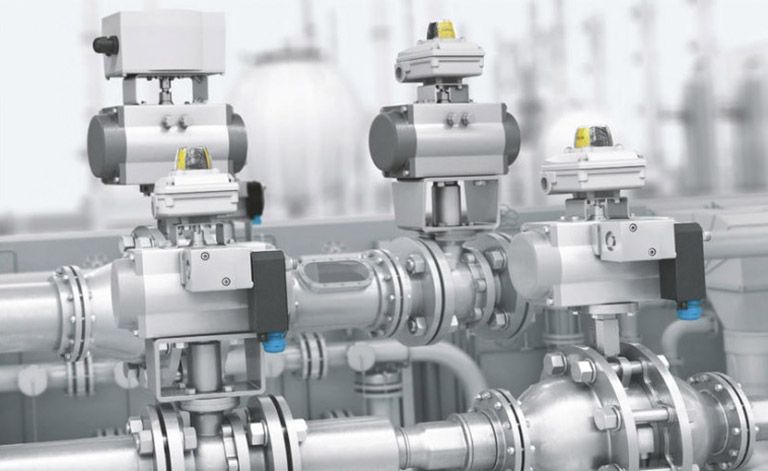

Ball Valve Maintenance Guide

Ball valves are renowned for their reliability and efficient fluid control in industrial and OEM applications. This quarter-turn on/off valve utilizes a rotating ball to manage the flow of gases and liquids, featuring a simple design and exceptional durability. While ball valves are often considered maintenance-free, regular inspections and maintenance are crucial for extending their lifespan. This guide will explore the importance of ball valve maintenance, the benefits it offers, and the factors influencing their longevity, helping you ensure safety and efficiency in your operations.

Table of contents

Importance of Ball Valve Maintenance

Ball valves are renowned for their reliability in industrial and OEM applications. This quarter-turn on/off valve features a rotating ball that effectively controls the flow of gases and fluids. Its simple design allows the hollow ball to rotate within the valve body, enabling media flow through manual or automated mechanisms. Compared to gate and globe valves, ball valves are often favored for several reasons:

- Compact and Cost-Effective Design

- Rapid Closing Speed

- Durability in High-Pressure, High-Capacity, and High-Temperature Conditions

- Resistance to Corrosion and Damage

- Extended Service Life

- Versatility Across Various Industries

Ball valves find applications in sectors such as oil and gas, chemical processing, agriculture, food and beverage, mechanical engineering, and automotive manufacturing. It’s crucial for these valves to meet the American Society of Mechanical Engineers (ASME) standards for process piping (ASME B31.3), which govern materials, components, designs, and assembly practices.

Although ball valves are built to last, they can experience wear over time. Most are designed to be maintenance-free and are often replaced rather than repaired. Three-piece ball valves are particularly suitable for high-cycles or high-pressure applications where seals may wear more rapidly. Implementing proper preventive measures can significantly extend their lifespan.

Benefits of Ball Valve Maintenance

1. Longevity

Regular maintenance leads to longer service lives for valves, reducing costs, preventing downtime, and ensuring consistent production. Neglecting maintenance can result in unnoticed issues, leading to equipment failure, part damage, or worker injuries.

2. Safety and Assurance

Preventable accidents are a major concern in industrial environments. Well-trained maintenance personnel can identify potential issues early, minimizing the risk of emergency repairs or OSHA violations. Properly maintained ball valves help prevent hazardous leaks in piping and processing systems.

3. Reduced Downtime

Downtime is costly; any interruption in production equates to lost revenue. Many maintenance tasks can be performed while the valve is operational, allowing for continuous production.

4. Cost Savings

Higher uptime translates to increased revenue, while fewer maintenance issues lead to significant cost savings. Regular inspections, maintenance, and timely replacements help avoid emergency repairs.

Factors Influencing Ball Valve Lifespan

Many manufacturers provide lifespan estimates for ball valves, but several factors can influence longevity:

Drive Type

Ball valves may be manually or automatically actuated. Choosing the right actuation method—pneumatic, electric, or hydraulic—based on expected cycle rates can reduce maintenance costs and enhance safety.

Design

Ball valves come in single-piece, two-piece, and three-piece designs. Single and two-piece valves are typically maintenance-free and require complete replacement when they fail. In contrast, three-piece valves allow for easy replacement of seats and seals without removing the entire valve from the system, making them ideal for high-cycling and high-pressure applications.

Maintainability

Seals are often the first components to fail due to their softer material compared to the valve body. In single and two-piece valves, seals must be completely replaced, while three-piece valves allow for simple seal replacement without full disassembly.

Temperature and Pressure Ratings

Valves operating in high-pressure or high-cycle environments require more frequent maintenance. The temperature and pressure of the media affect the materials used for the valve. The closer these conditions are to the valve’s ratings, the more often replacements may be necessary.

Fortunately, actuators, which are often more expensive components, generally outlast the ball valves they control. Replacing a valve usually doesn’t require actuator replacement.

Media

Ball valves are designed to control the flow of fluids and gases that do not contain solid particles. Solid particles can wear down valve seals, leading to repairs or failures. On the other hand, lubricating media can reduce seal wear and extend valve lifespan.

Valve Material

The type of media plays a significant role in determining the valve body and fittings material. Ball valves can be constructed from stainless steel, brass, bronze, or plastic (PVC). While PVC is flexible and cost-effective, metal ball valves are more durable and better suited for high temperatures and pressures. Generally, metal valves have a longer lifespan than those made from PVC or synthetic materials. For assistance with suitable valve materials, consult the Cole-Parmer chemical compatibility database to ensure compatibility with your specific media.

By understanding and implementing effective maintenance practices, you can significantly enhance the performance and longevity of your ball valves, ultimately contributing to safer and more efficient industrial operations.

Summary

In summary, regular maintenance of ball valves is essential for ensuring their reliability and extending their lifespan in various industrial applications. While these valves are designed for durability, neglecting maintenance can lead to significant issues, including equipment failures and safety hazards. Key benefits of proper maintenance include increased longevity, enhanced safety, reduced downtime, and cost savings. Factors such as drive type, design, maintainability, temperature and pressure ratings, media type, and valve material all play a crucial role in determining the lifespan of ball valves. By implementing effective maintenance practices, you can optimize performance and ensure the safe operation of your systems.

Why more and more international valve brands choose DELCO for OEM service?

Founded in 2011, DELCO is a global leader in the industrial sector. Our main products include electric actuator valves, pneumatic actuator valves, automation actuators and solenoid valves. For nearly 20 years, we have utilized our products, engineering expertise and industrial automation solutions to solve countless industrial project problems for our customers, including food, beverage, chemical, water treatment, pharmaceutical, natural gas, oil and HVAC projects. We currently have five subsidiaries and more than 50 distributors around the world providing rapid response service.

All DELCO products undergo a 100% in-house design, engineering and manufacturing process led by highly skilled and experienced engineers using Italian and German technology to manufacture high quality, safe, reliable and value for money valves, actuators and solutions. Manufacturing standards can be demonstrated by the certifications obtained over the years.

And with the ISO 9001:2015 Quality Management System certification as well as many other certifications such as: SGS, RoHS, CNEX, TUV, CE, FDA. these certifications prove that DELCO adheres to the highest quality and safety standards worldwide when manufacturing its products.

How to get a quick quote for industrial valves?

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email marketing [email protected].

DELCO’s quality, competitive prices and excellent service make it the best valve partner to help you grow your business. Customize your valves, we have no minimum order.

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.