Tech Theory: Technical…Practical… Interesting Automation Industrial Solutions

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control air supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

What is a Gate Valve?

Gate valves Overview

A gate valve is designed to either fully allow or fully block the flow of fluids. Its key advantage is the unobstructed passage, which minimizes pressure loss and accommodates cleaning procedures using pigs. Gate valves are slower than quarter-turn valves and are best used in either fully open or fully closed positions rather than for flow regulation. Automated versions with electric or pneumatic actuators are available, but manual gate valves are often more cost-effective due to their infrequent use. These valves are also known as sluice gate valves.

Gate valves Operation

Gate valves operate by turning a handwheel to move a gate up or down. This movement opens or closes the flow path, requiring multiple turns of the handwheel to fully open or close the valve. The gate valve is ideal for on/off control with minimal pressure drop when fully open. It is not suitable for throttling due to its design and the nonlinear relationship between gate travel and flow rate.

Types of Gate Valves

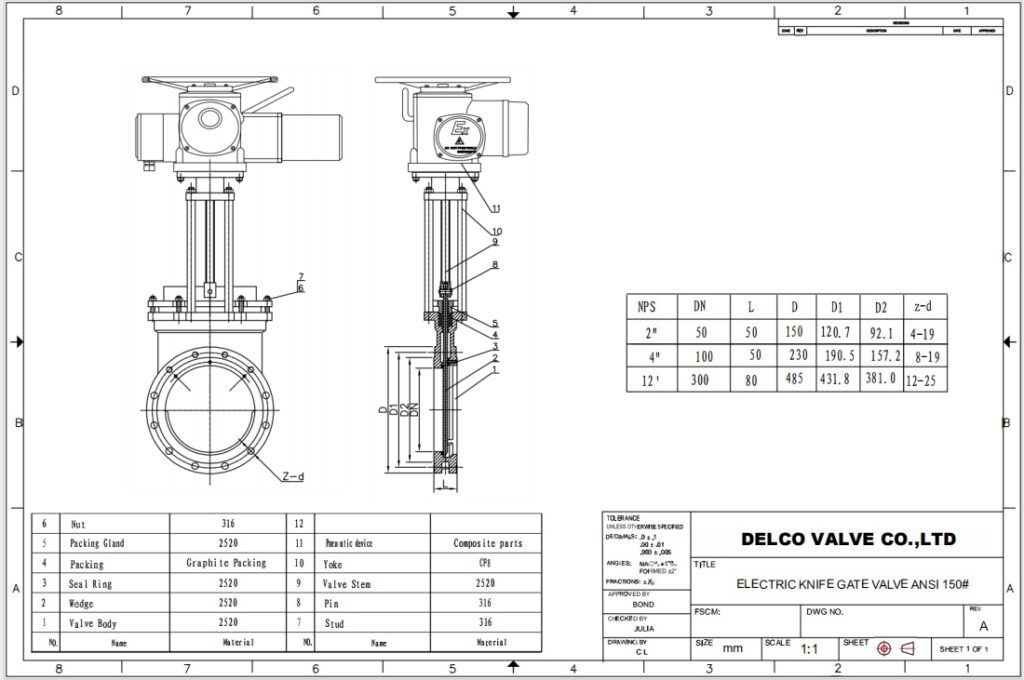

Knife Gate Valve: Suitable for thick fluids and dry bulk solids. The gate is a sharp, single-piece metal design that cleans the seat with each operation.

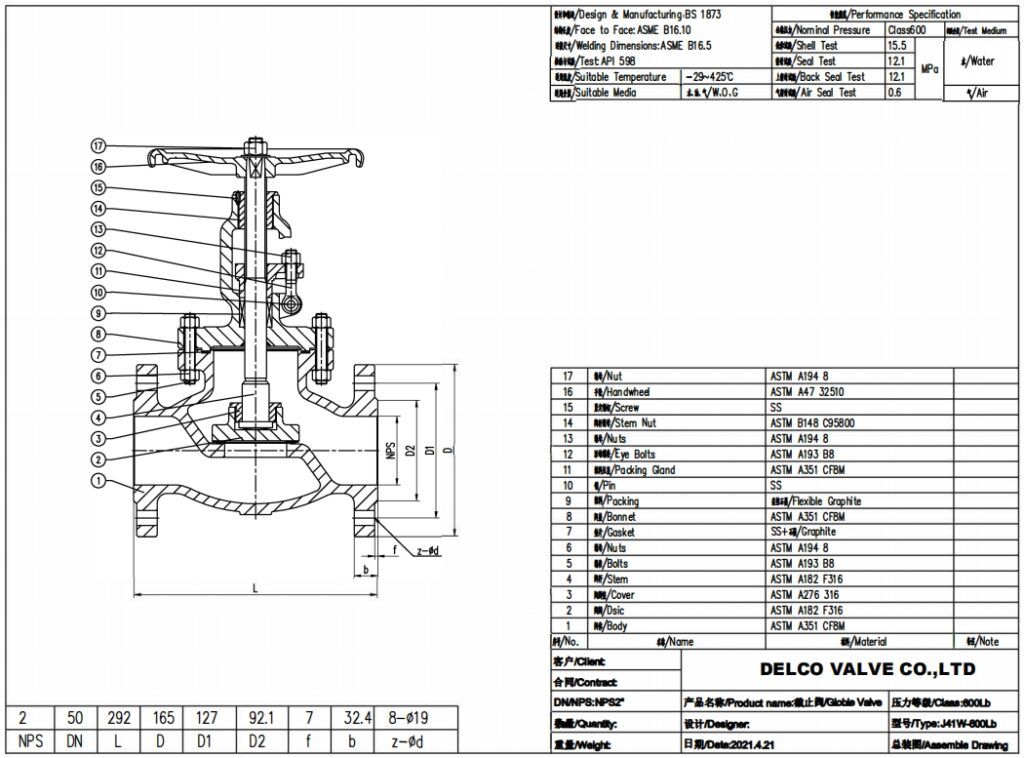

Wedge Gate Valve: Features a wedge-shaped gate that sits on inclined seats, enhancing sealing through wedging force.

Parallel Slide Gate Valve: Utilizes a flat gate and parallel seats with a spring mechanism for enhanced sealing.

Slab Gate Valve: Known as through-conduit valves, they have a bore-size hole aligned with seat rings for smooth flow and minimal pressure loss.

Parallel Expanding Gate Valve: Combines two slab gates that expand mechanically to create a seal.

Actuation Methods

- Manual Gate Valve: Operated by a handwheel, ideal for infrequent use.

- Pneumatic Gate Valve: Uses a pneumatic actuator for remote operation.

- Electric Gate Valve: Features an electric motor for remote control.

Bonnets

The bonnet of a gate valve provides a leak-proof seal and is removable for maintenance. Types include screw-in, union, bolted, and pressure seal bonnets, each suited to different applications and pressure requirements.

Stem Design

- Rising Stem (OS&Y): Moves with the gate, providing visual indicators of valve status.

- Non-Rising Stem: Fixed to the actuator, suitable for confined spaces.

Applications

Gate valves are used in various industries and applications:

- Slurries: Due to their unobstructed passageway.

- Viscous Media: Ideal for fluids like grease and oils.

- Water: Common in systems where flow control is either fully open or fully closed.

Why more and more international valve brands choose DELCO for OEM service?

Founded in 2011, DELCO is a global leader in the industrial sector. Our main products include electric actuator valves, pneumatic actuator valves, automation actuators and solenoid valves. For nearly 20 years, we have utilized our products, engineering expertise and industrial automation solutions to solve countless industrial project problems for our customers, including food, beverage, chemical, water treatment, pharmaceutical, natural gas, oil and HVAC projects. We currently have five subsidiaries and more than 50 distributors around the world providing rapid response service.

All DELCO products undergo a 100% in-house design, engineering and manufacturing process led by highly skilled and experienced engineers using Italian and German technology to manufacture high quality, safe, reliable and value for money valves, actuators and solutions. Manufacturing standards can be demonstrated by the certifications obtained over the years.

And with the ISO 9001:2015 Quality Management System certification as well as many other certifications such as: SGS, RoHS, CNEX, TUV, CE, FDA. these certifications prove that DELCO adheres to the highest quality and safety standards worldwide when manufacturing its products.

How to get a quick quote for industrial valves?

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email marketing [email protected].

DELCO’s quality, competitive prices and excellent service make it the best valve partner to help you grow your business. Customize your valves, we have no minimum order.

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.