Tech Theory: Technical…Practical… Interesting Automation Industrial Solutions

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control air supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

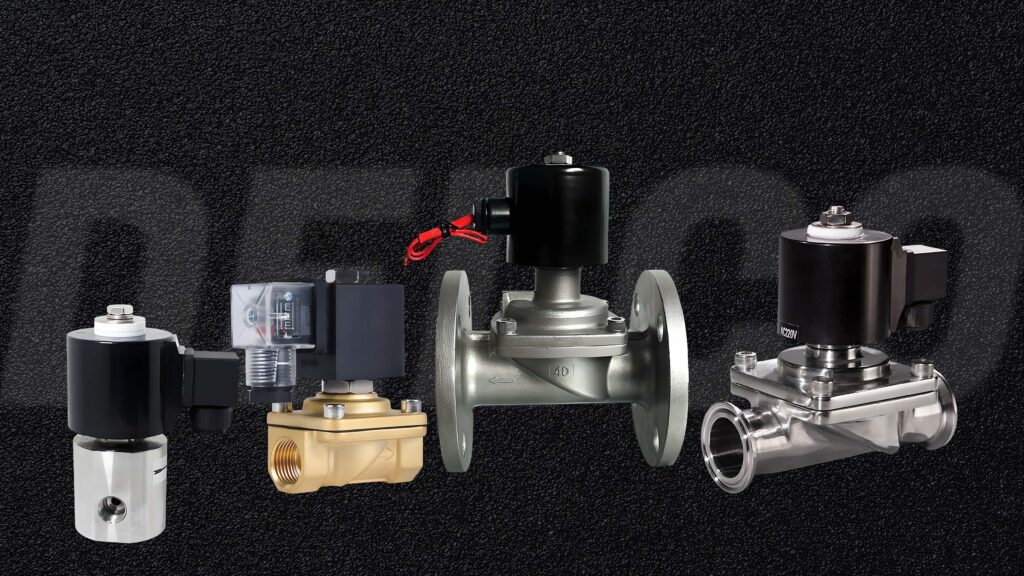

Mastering Solenoid Valves: A Complete Exploration

Unraveling the Intricacies of Solenoid Valves: A Comprehensive Guide

In the vast landscape of industrial automation and fluid control systems, solenoid valves stand as indispensable components. These electromechanical devices play a pivotal role in regulating the flow of fluids, whether it be liquid or gas, across a myriad of applications. This comprehensive guide endeavors to delve deep into the realm of solenoid valves, elucidating their principles, types, applications, advantages, and key considerations for selection.

Solenoid valves, often referred to as electromechanical valves, operate on the principle of electromagnetism. At its core, a solenoid valve comprises a coil, plunger, and valve seat. When an electric current passes through the coil, it generates a magnetic field that attracts or repels the plunger, thereby controlling the flow of fluid through the valve seat. This mechanism enables precise and swift regulation of fluid flow, making solenoid valves indispensable across various industries and sectors.

Types of Solenoid Valves

1. Direct-Acting Solenoid Valves

Direct-acting solenoid valves operate by directly lifting the valve seat to allow fluid flow when the coil is energized. These valves are commonly used in applications with low pressure and flow rates.

2. Pilot-Operated Solenoid Valves

Pilot-operated solenoid valves utilize a smaller solenoid to control the flow of a larger fluid supply. They are ideal for applications requiring higher pressure and flow rates, offering enhanced performance and reliability.

Applications of Solenoid Valves

Solenoid valves find applications across a diverse array of industries and sectors, owing to their versatility, reliability, and precision. Some common applications include:

Water and Wastewater Management: Used for controlling the flow of water and chemicals in treatment plants, irrigation systems, and plumbing fixtures.

HVAC Systems: Employed for regulating the flow of refrigerants and fluids in heating, ventilation, and air conditioning systems, ensuring optimal thermal comfort.

Automotive Industry: Integrated into fuel injection systems, transmission control, and emission control systems in vehicles, ensuring efficient operation and reduced emissions.

Medical Equipment: Utilized in medical devices such as blood analyzers, dialysis machines, and diagnostic equipment, ensuring accurate fluid control and dosage delivery.

Manufacturing and Industrial Processes: Deployed in various manufacturing and industrial processes for fluid control, automation, and process optimization.

Advantages of Solenoid Valves

1. Precise Control: Solenoid valves offer precise and accurate control over fluid flow, allowing for tailored adjustments to meet specific requirements.

2. Rapid Response Time: These valves can open and close in milliseconds, ensuring swift actuation and response to changing flow conditions.

3. Energy Efficiency: Solenoid valves consume minimal energy when in the closed position, contributing to energy savings and operational efficiency.

4. Reliability and Durability: With fewer moving parts and robust construction, solenoid valves offer reliable performance and long service life, even in demanding environments.

Key Considerations for Selection

When selecting solenoid valves for your application, several factors should be taken into account to ensure optimal performance and compatibility:

Fluid Compatibility: Verify that the valve materials are compatible with the fluid being controlled to prevent corrosion, contamination, or degradation.

Pressure and Temperature Ratings: Select valves that can withstand the operating pressure and temperature conditions of your application without compromising performance or safety.

Valve Size and Flow Rate: Choose the appropriate valve size and flow rate to match the requirements of your system and ensure efficient fluid control.

Voltage and Power Requirements: Ensure that the valve operates at the correct voltage and power levels for your electrical system, preventing potential damage or malfunction.

Conclusion

Solenoid valves stand as indispensable components in the realm of industrial automation and fluid control systems, offering precise, reliable, and efficient fluid regulation across diverse applications. By understanding the principles, types, applications, advantages, and key considerations for selection of solenoid valves, you can make informed decisions when integrating these valves into your systems. With the right choice, you can enhance the efficiency, reliability, and performance of your fluid control processes, leading to improved productivity, cost savings, and operational excellence.

Why more and more international valve brands choose DELCO for OEM service?

Founded in 2011, DELCO is a global leader in the industrial sector. Our main products include electric actuator valves, pneumatic actuator valves, automation actuators and solenoid valves. For nearly 20 years, we have utilized our products, engineering expertise and industrial automation solutions to solve countless industrial project problems for our customers, including food, beverage, chemical, water treatment, pharmaceutical, natural gas, oil and HVAC projects. We currently have five subsidiaries and more than 50 distributors around the world providing rapid response service.

All DELCO products undergo a 100% in-house design, engineering and manufacturing process led by highly skilled and experienced engineers using Italian and German technology to manufacture high quality, safe, reliable and value for money valves, actuators and solutions. Manufacturing standards can be demonstrated by the certifications obtained over the years.

And with the ISO 9001:2015 Quality Management System certification as well as many other certifications such as: SGS, RoHS, CNEX, TUV, CE, FDA. these certifications prove that DELCO adheres to the highest quality and safety standards worldwide when manufacturing its products.

How to get a quick quote for industrial valves?

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email marketing [email protected].

DELCO’s quality, competitive prices and excellent service make it the best valve partner to help you grow your business. Customize your valves, we have no minimum order.

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.

Products

Social Media

- Phone

- Address

FUXIANG Industrial Building, Guancheng,Dongguan,China

© 2024 GuangDong DELCO Co., Ltd.

Privacy Policy Terms & Conditions