Tech Theory: Technical…Practical… Interesting Automation Industrial Solutions

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control air supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Exploring Multi-Turn Motorized Valves: What You Need to Know

Introduction

When it comes to industrial automation and fluid control systems, multi-turn motorized valves are essential components. These valves are crucial for regulating the flow of liquids, gases, and other materials in various applications, including water treatment, HVAC systems, chemical processing, and power generation. In this article, we’ll dive into the details of multi-turn motorized valves, explaining their functionality, types, applications, benefits, and key considerations for choosing the right valve for your needs.

What Are Multi-Turn Motorized Valves?

Multi-turn motorized valves are automated devices designed to control the flow of media by turning a valve stem multiple times to open or close the valve completely. Unlike quarter-turn valves, which require only a 90-degree rotation, multi-turn valves need several rotations to transition from fully open to fully closed. This design allows for precise control over the flow rate, making them ideal for applications requiring fine adjustments.

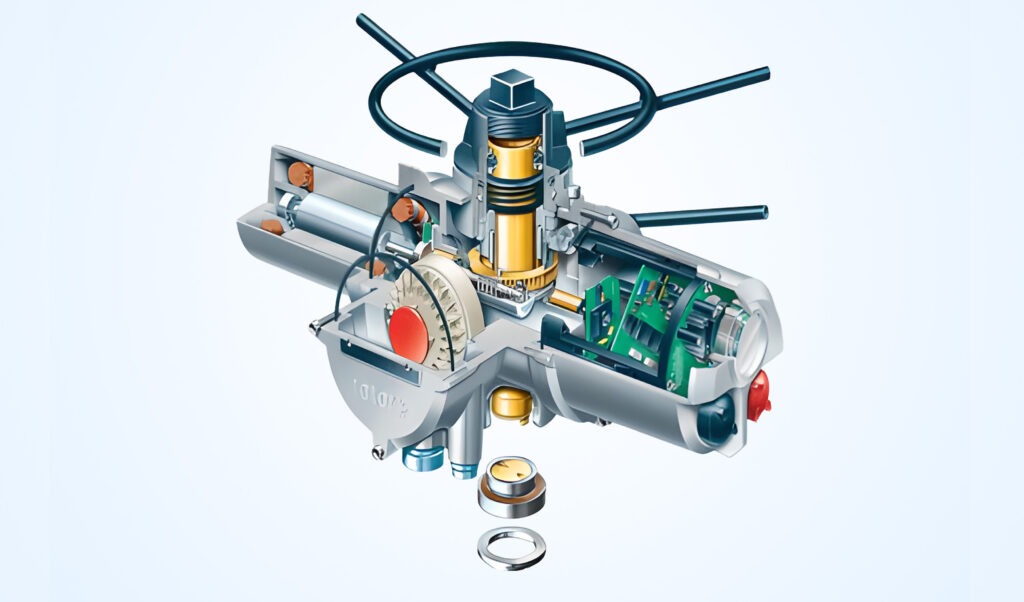

Components of Multi-Turn Motorized Valves

Valve Body: The main structure housing the internal components and providing the pathway for the fluid.

Valve Stem: The rod that connects the actuator to the valve disc, gate, or plug, transferring the motion to open or close the valve.

Actuator: The motorized mechanism that drives the valve stem. It can be electric, pneumatic, or hydraulic.

Disc, Gate, or Plug: The internal component that moves to regulate the flow through the valve.

Seals and Gaskets: These components ensure a leak-proof operation by preventing fluid from escaping the valve body.

Types of Multi-Turn Motorized Valves

Gate Valves: Used for on/off control of the flow, they have a gate (wedge) that moves up and down to open or close the flow path.

Globe Valves: Ideal for throttling applications, they have a movable disc (or plug) that adjusts the flow rate by changing the position relative to a stationary ring seat.

Diaphragm Valves: Utilize a flexible diaphragm that moves up and down to control the flow. These are often used in applications requiring contamination-free operation.

Needle Valves: Provide precise flow control by using a needle-shaped plunger that fits into a conical seat.

How Multi-Turn Motorized Valves Work

Multi-turn motorized valves operate by converting the rotational motion of an electric, pneumatic, or hydraulic actuator into linear motion that moves the valve stem. The actuator receives a control signal, typically from a remote control system, and rotates the valve stem multiple times to achieve the desired position. This precise control mechanism makes them suitable for applications requiring accurate flow regulation.

Electric Actuators

Electric actuators are the most common type used in multi-turn motorized valves. They are powered by an electric motor and can be controlled remotely via a control panel or automation system. Electric actuators offer several advantages, including precise control, easy integration with control systems, and low maintenance requirements.

Pneumatic Actuators

Pneumatic actuators use compressed air to drive the valve stem. They are preferred in environments where electric actuators might pose a risk, such as explosive atmospheres. Pneumatic actuators are known for their fast response times and high force output, making them suitable for heavy-duty applications.

Hydraulic Actuators

Hydraulic actuators operate using pressurized hydraulic fluid. They are capable of providing high force and precise control, even in demanding conditions. Hydraulic actuators are often used in applications where electric or pneumatic actuators may not be suitable due to space constraints or environmental factors.

Applications of Multi-Turn Motorized Valves

Multi-turn motorized valves are used in a wide range of industries and applications due to their versatility and precision. Some of the common applications include:

Water and Wastewater Treatment

In water and wastewater treatment plants, multi-turn motorized valves are used to control the flow of water through various treatment processes. They ensure precise regulation of flow rates, which is essential for maintaining the efficiency and effectiveness of the treatment processes.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely on multi-turn motorized valves to regulate the flow of air and water in the system. These valves help maintain optimal temperature and humidity levels, ensuring a comfortable indoor environment.

Chemical Processing

In chemical processing plants, precise control of fluid flow is crucial for maintaining the quality and consistency of the final product. Multi-turn motorized valves provide the necessary accuracy and reliability to manage the flow of chemicals through various stages of production.

Power Generation

Power plants use multi-turn motorized valves to control the flow of steam, water, and other fluids. These valves play a vital role in regulating the pressure and temperature within the plant, ensuring safe and efficient operation.

Oil and Gas Industry

The oil and gas industry relies on multi-turn motorized valves for controlling the flow of crude oil, natural gas, and other hydrocarbons. These valves are used in various stages of production, transportation, and refining, providing precise control and ensuring safety in the process.

Key Considerations for Selecting Multi-Turn Motorized Valves

When selecting multi-turn motorized valves for your application, several factors need to be considered to ensure optimal performance and reliability:

Valve Type

Choose the appropriate valve type (gate, globe, diaphragm, or needle) based on the specific requirements of your application. Each type offers unique advantages and is suitable for different flow control tasks.

Actuator Type

Consider the type of actuator (electric, pneumatic, or hydraulic) that best suits your application. Electric actuators are ideal for precise control and automation, while pneumatic and hydraulic actuators are better suited for heavy-duty and hazardous environments.

Material Compatibility

Ensure that the valve materials are compatible with the media being controlled. For example, stainless steel valves are suitable for corrosive fluids, while UPVC valves are ideal for water and wastewater applications.

Pressure and Temperature Ratings

Verify that the valve can handle the operating pressure and temperature conditions of your application. Selecting a valve with the appropriate ratings ensures safe and reliable performance.

Control System Integration

Consider how the valve will be integrated into your control system. Ensure that the actuator is compatible with your existing control infrastructure and can be easily programmed for remote operation.

Conclusion

Multi-turn motorized valves are indispensable components in modern industrial automation and fluid control systems. Their ability to provide precise flow regulation, remote control, and reliable performance makes them ideal for a wide range of applications. By understanding the different types, functionalities, and benefits of multi-turn motorized valves, you can make informed decisions when selecting the right valve for your specific needs. With the right choice, you can enhance the efficiency, safety, and reliability of your industrial processes, ensuring long-term success and productivity.

How to get a quick quote for industrial valves?

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email marketing [email protected].

DELCO’s quality, competitive prices and excellent service make it the best valve partner to help you grow your business. Customize your valves, we have no minimum order.

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.