DELCO Electric temperature control valves-ZZWPE

In the realm of thermal management systems, the electrical temperature control valves emerges as a cutting-edge solution, revolutionizing the way temperature is regulated in various industrial processes, HVAC systems, and other applications. Combining advanced electronics with precision engineering, these valves offer unparalleled control and performance, enabling precise temperature modulation and optimization in fluid-based heating and cooling systems.

DELCO group aims to provide our customers the best quality products with the most competitive pricing, on-time delivery and full warranty service.

Model: Electrical temperature control valve

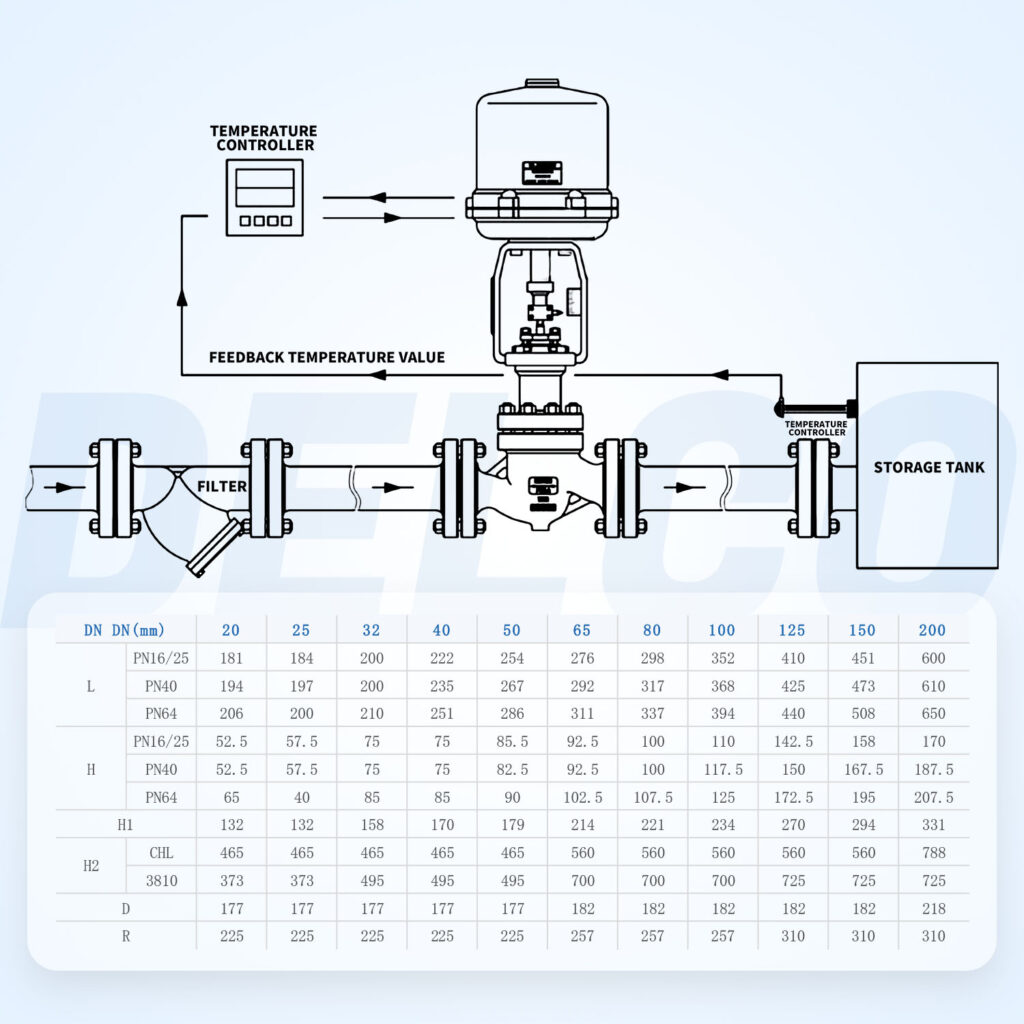

Size Range: 1/2” to 12”

Pressure Range: 1.6 to 6.4MPa

Material: Stainless Steel 304/316 or WCB

Description

The electrical temperature control valves represents a significant advancement in the field of thermal management technology. Unlike traditional valves that rely on mechanical mechanisms for temperature regulation, electrical temperature control valves utilize electronic actuators to precisely modulate the flow of fluids based on temperature feedback from sensors. This innovative approach allows for highly accurate and responsive temperature control, ensuring optimal thermal conditions in a wide range of applications.

At the core of an electrical temperature control valves is its electronic actuator, which receives signals from temperature sensors to adjust the valve’s position in real-time. As the temperature of the fluid being controlled changes, the actuator responds by opening or closing the valve to maintain the desired temperature setpoint. This dynamic control mechanism enables the valve to accurately regulate the flow of fluids, ensuring consistent temperatures throughout the system.

In conclusion, the electrical temperature control valves represents a significant advancement in thermal management technology, offering precise and efficient temperature regulation in various industrial, commercial, and residential applications. With their advanced electronic control systems, these valves provide unparalleled accuracy and responsiveness, ensuring optimal thermal conditions and energy efficiency in fluid-based heating and cooling systems. As technology continues to evolve, electrical temperature control valves will remain at the forefront of thermal management innovation, driving efficiency, reliability, and performance in thermal control systems worldwide.

Actuator Parameter

| Actuator model | Main technical parameters: | Warm bag, capillary material | Capillary length | Temperature control range | Deviation from the setpoint | ||

| 3810 series, PSL series | Power supply voltage: 220V/50Hz, input signal: 4-20mA or 1-5V· DC, output signal: 4-20mA· DC | Protection level: equivalent to IP55, flameproof mark: ExdII.BT4, manual function: handle | Ambient temperature: -25~+70°C, Ambient humidity: ≤95% |

H62、1Cr18Ni9Ti | 3 Rice, 5 Rice, 10 Rice | 0~250℃ | ±2℃ |

| Valve body form | Nominal diameter | Nominal pressure | Flange standard | Form of connection | Bonnet form | Gland type | Sealing packing |

| Straight-through ball valve | DN15~300mm | PN1.6、2.5、4.0、6.4MPa | GB/T9113、 JB/T79 | Flange (FF RF RTJ), Welded (SW BW), Threaded (for up to 1″) | Standard type -17~+230°C, high temperature type +230~+450°C | Bolt-on press-down | V-type PTFE filler, impregnated PTFE asbestos filler, asbestos textile filler, graphite filler |

Temperature Control Valves

Electrical Temperature Control Valves Applications:

The versatility and precision of electrical temperature control valves make them indispensable in a variety of applications across different industries. Some common applications include:

HVAC Systems: These valves are used in heating, ventilation, and air conditioning systems to regulate the flow of hot and cold water, ensuring precise temperature control in commercial and residential buildings.

Industrial Processes: In industrial applications such as chemical manufacturing, food processing, and pharmaceutical production, electrical temperature control valves play a crucial role in maintaining precise temperature conditions for optimal process efficiency and product quality.

Thermal Management Systems: Electrical temperature control valves are employed in thermal management systems for electronic equipment, automotive engines, and power generation plants to regulate coolant flow and maintain optimal operating temperatures.

Electrical Temperature Control Valves Advantages:

Precision Control: With their electronic actuators and temperature feedback loops, electrical temperature control valves offer precise and responsive temperature regulation, ensuring consistent thermal conditions in fluid-based systems.

Energy Efficiency: By maintaining precise temperature setpoints, these valves help optimize energy usage in heating and cooling systems, reducing energy consumption and operating costs.

Versatility: Electrical temperature control valves are highly adaptable and can be customized to meet the specific requirements of different applications, making them suitable for a wide range of thermal management tasks.

Remote Monitoring and Control: Many electrical temperature control valves are equipped with advanced communication interfaces, allowing for remote monitoring and control via computerized systems, enhancing system flexibility and efficiency.

One-time business is not our goal, we pursuit for long-term partner relationships.

We are not just providing simple quotes but experts in selection, calculation, and drawing.

ASK FOR A QUOTE

Related products

Offering Industry-Oriented Valve Solution For You

The company not only controls the quality in real time, but also zero tolerance for problems is the pursuit of high quality. Workers must undergo rigorous training and strict assessment before they can take up their jobs.

Quality Assurance

Calculation & Selection, Quality Control, Inspection, After-Sales Service, etc. Each Production Loop to Ensure Our Customers Have No Worries.

Services

At DELCO, we believe there always has a better valve solution for every single customer. We’re obsessively passionate about it, and our mission is to manufactures & supply a range of innovative control valves & pressure regulators backed by global service support, thereby guaranteeing zero defects within the shortest lead time.

Production Market

DELCO Has A Wide Reach, Exporting To Over 46 Nations. So We Have A Complete Picture Of The Market. Welcome To Become A Long-Term Business Partner With Us. Reliable Control Valves and Self-Operated Pressure RegulatorsManufacturer

Company Honor

DELCO valve has CE, RoHS, FDA, Explosion-proof electrical apparatus.

For over 20 years, DELCO Valves has been committed to providing our customers with high quality valves.

DELCO has always been centered around one thing: 100% customer satisfaction. We strive for continuous improvement in all aspects of our daily operations. Our mission, coupled with a product line that is manufactured to the highest quality standards, continues to be what sets us apart from our competition. At Powell, all of our facilities are ISO 9001 “Global Quality” certified.

As a leading manufacturer of industrial valves, we offer a wide range of products. Our product lines include: gate valves, check valves, globe valves, check valves, double plate check valves and high performance butterfly valves. With the most complete multi-turn product line from a single-source manufacturer, our valves are manufactured to the highest quality standards using ultra-modern manufacturing techniques and astute material sourcing.

As a full-service valve company, we offer a wide range of products as well as retrofit and field services. Our valve expertise is unrivaled and we look forward to meeting your future valve needs!