Control Valve solutions

DELCO Provide Various Optimal Solution For Industrial Valves, Especially For Control Valves.

- Home

- »

- control valve solutions

Control Valve Applications

-

Water Treatment

-

water purification project

-

Ultrafiltration Membrane Syste

-

Irrigation system

-

Drinking Water Treatment Project

-

Wastewater Treatment Project

Water Treatment

Industrial Valves Used For Water Treatment

Water treatment refers to the process of treating water to ensure it meets specific quality standards to fulfill the needs of industrial, commercial, or household water usage. In the water treatment industry, industrial valves play a crucial role in controlling and regulating water flow, ensuring the smooth operation of various treatment stages.

DELCO Valves Solutions

Industrial valves provide multiple solutions for water treatment, including:

Flow regulation: Industrial valves can regulate the flow rate in water treatment systems, ensuring that the flow of water meets the requirements at different treatment stages, thereby facilitating effective treatment processes.

Pressure control: By adjusting the valve’s opening, pressure in water treatment systems can be controlled, ensuring stable system operation and preventing pipeline ruptures or leaks.

Medium selection: Industrial valves made of different materials and designs can be used to treat different types of water, such as fresh water, seawater, wastewater, etc., and to address different water quality issues such as corrosion, pollutants, and microorganisms.

Automated control: Industrial valves can be integrated with automated control systems for remote monitoring and automatic adjustment, improving the efficiency and reliability of water treatment systems.

Safety assurance: Some industrial valves have safety features, such as emergency shut-off valves, which automatically close in case of abnormal system conditions, preventing accidents.

Related Products

- Butterfly Valve

- Piston Valve

- Knife Gate Valve

- Automatic Air Valve

- Gate Valve

- Plug Valve

- Check Valve

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.

Water Purification Project

Industrial Valves Used For Water Purification Project

Water purification is a critical process in ensuring the availability of clean and safe water for various uses, including drinking, industrial processes, and irrigation. This process involves the removal of undesirable chemicals, biological contaminants, suspended solids, and gases from water. The goal is to produce water that is fit for specific purposes.

Industrial valves play a crucial role in the water purification process, offering precise control, reliability, and efficiency in managing the flow and treatment of water.

The Role of Industrial Valves in Water Purification:

1. Control and Regulation: Industrial valves control the flow of water and treatment chemicals throughout the purification process. They regulate the rate of flow and maintain the correct pressure levels within the system, ensuring that each phase of the purification process occurs under optimal conditions.

2. Isolation and Safety: Valves provide isolation for maintenance, emergency shutoff, and system integrity. They can isolate sections of the purification plant for maintenance or in response to a system failure, preventing contamination and ensuring the safety of the water supply.

3. Precision in Chemical Treatment: In the stages of water purification that require chemical treatment, such as disinfection or pH adjustment, valves ensure the precise dosing of chemicals. This precision is crucial for effective treatment and for maintaining the balance of chemical concentrations to avoid over or under-treatment.

4. Backflow Prevention: Certain types of industrial valves, such as check valves, prevent backflow, ensuring that purified water does not mix with untreated water or chemicals, thus maintaining the integrity of the purified water.

5. Durability and Reliability: Valves used in water purification must withstand corrosive substances and varying pressures and temperatures. Materials like stainless steel, PVC, and other corrosion-resistant materials are commonly used to enhance durability and reliability.

DELCO Solutions

Solutions Provided by Industrial Valves for Water Purification:

1. Control and Regulation: Industrial valves control the flow of water and treatment chemicals throughout the purification process. They regulate the rate of flow and maintain the correct pressure levels within the system, ensuring that each phase of the purification process occurs under optimal conditions.

2. Isolation and Safety: Valves provide isolation for maintenance, emergency shutoff, and system integrity. They can isolate sections of the purification plant for maintenance or in response to a system failure, preventing contamination and ensuring the safety of the water supply.

3. Precision in Chemical Treatment: In the stages of water purification that require chemical treatment, such as disinfection or pH adjustment, valves ensure the precise dosing of chemicals. This precision is crucial for effective treatment and for maintaining the balance of chemical concentrations to avoid over or under-treatment.

4. Backflow Prevention: Certain types of industrial valves, such as check valves, prevent backflow, ensuring that purified water does not mix with untreated water or chemicals, thus maintaining the integrity of the purified water.

5. Durability and Reliability: Valves used in water purification must withstand corrosive substances and varying pressures and temperatures. Materials like stainless steel, PVC, and other corrosion-resistant materials are commonly used to enhance durability and reliability.

Related Products

- Butterfly Valve

- Piston Valve

- Knife Gate Valve

- Automatic Air Valve

- Plug Valve

- Check Valve

- Gate Valve

Ultrafiltration Membrane Syste

Industrial Valves Used For Ultrafiltration Membrane Syste

Ultrafiltration membrane systems are advanced filtration systems designed to purify water by removing suspended solids, bacteria, viruses, and other contaminants. These systems utilize semi-permeable membranes with fine pores that allow water molecules to pass through while blocking larger particles and impurities. Ultrafiltration technology is widely used in various industries, including water treatment, food and beverage, pharmaceuticals, and electronics manufacturing, to produce high-quality water for different purposes.

Key Features of Ultrafiltration Membrane Systems:

Fine Filtration: Ultrafiltration membranes have pore sizes ranging from 0.1 to 0.01 microns, making them highly effective in removing particles, bacteria, and pathogens from water.

High Efficiency: These systems offer high filtration efficiency, with removal rates exceeding 99% for most contaminants, ensuring the production of clean and safe water.

Low Operating Costs: Ultrafiltration membranes require minimal chemical usage and produce less waste compared to traditional filtration methods, resulting in lower operating costs and environmental impact.

Compact Design: Ultrafiltration membrane systems are compact and modular, allowing for easy installation and scalability to meet varying water treatment demands.

Versatility: These systems can be customized to treat various water sources, including surface water, groundwater, seawater, and wastewater, making them suitable for a wide range of applications.

DELCO Valves Solutions

Industrial Valves Solutions for Ultrafiltration Membrane Systems:

Industrial valves play a crucial role in the operation and control of ultrafiltration membrane systems, providing precise fluid handling and regulation throughout the purification process. Here are some key solutions offered by industrial valves for ultrafiltration membrane systems:

Feed Water Control: Valves regulate the flow of feed water into the ultrafiltration system, ensuring a consistent and controlled flow rate for optimal membrane performance.

Pressure Regulation: Pressure control valves maintain the required pressure levels within the ultrafiltration system, preventing membrane damage and ensuring efficient filtration.

Backwash and Cleaning: Valves facilitate the backwash and cleaning processes essential for maintaining membrane integrity and prolonging their lifespan. By controlling the flow of cleaning agents and backwash water, valves ensure thorough cleaning and removal of fouling substances from the membranes.

Product Water Distribution: Valves control the distribution of purified water from the ultrafiltration system to different points of use or storage tanks, ensuring reliable and efficient water supply throughout the facility.

Safety and Emergency Shut-off: Emergency shut-off valves provide fail-safe protection by automatically closing the water supply in case of system malfunction or pressure anomalies, preventing damage to the membranes and ensuring operational safety.

In conclusion, industrial valves are integral components of ultrafiltration membrane systems, providing essential control and regulation capabilities to optimize the performance, efficiency, and reliability of water purification processes. Their precise fluid handling solutions contribute to the production of high-quality, clean water for various industrial and commercial applications, ensuring compliance with regulatory standards and meeting the demands of modern water treatment practices.

Related Products

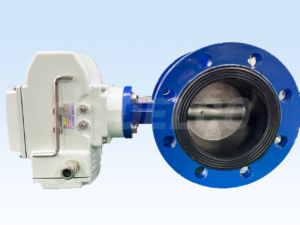

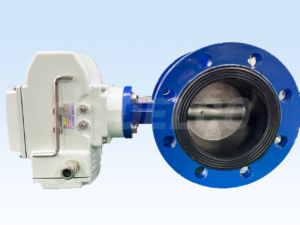

- Butterfly Valve

- Ball Valve

- Pneumatic Valve

- Electric Valve

- Butterfly Valve

- Actuator

- Solenoid Valve

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.

Pneumatic Globe Control Valve: A Comprehensive Guide

In modern industry, the Pneumatic Globe Control Valve is a highly efficient and precise fluid control device that is widely used in chemical, energy and heating systems. In this article, DELCO Valve will bring you a comprehensive understanding of this equipment from its working principle, characteristic advantages and application areas.

Electric Knife Gate Valve: Features, Applications and Selection Guide

In modern industry, Electric Knife Gate Valve is an important equipment in fluid control system. In this article, DELCO Valve will explain in detail its features and application areas to help you better understand and apply.

Electric Flange Butterfly Valve: A Comprehensive Guide

In industrial piping systems, Electric Flange Butterfly Valve is widely used in various fluid control scenarios. In this article, DELCO Valve will analyze its features, installation methods and application scenarios in detail, providing you with a complete reference guide.

lrrigation System

Industrial Valves Used For lrrigation System

Irrigation systems play a vital role in agricultural practices worldwide, providing controlled water supply to crops to enhance growth and yield. These systems are designed to efficiently distribute water to agricultural fields, gardens, and landscapes, ensuring optimal moisture levels for plant growth while conserving water resources. From traditional flood irrigation to advanced drip and sprinkler systems, irrigation technology continues to evolve, offering sustainable solutions to meet the demands of modern agriculture.

Key Components of an Irrigation System:

Water Source: Irrigation systems utilize various water sources such as rivers, lakes, reservoirs, wells, or recycled water to supply irrigation networks.

Distribution Network: Pipes, hoses, and channels form the distribution network, transporting water from the source to the fields or crops.

Control Valves: Industrial valves play a crucial role in controlling the flow of water within the irrigation system, allowing for precise regulation and distribution of water to different areas.

Emitters or Sprinklers: Emitters, sprinklers, or drip lines deliver water directly to plants, ensuring targeted and efficient water application.

Monitoring and Control Systems: Modern irrigation systems are equipped with sensors, controllers, and automation technology to monitor soil moisture levels, weather conditions, and water flow, enabling precise control and optimization of irrigation schedules.

DELCO Valves Solutions

Industrial Valve Solutions for Irrigation Systems:

Industrial valves are essential components of irrigation systems, providing precise control and regulation of water flow to ensure efficient water distribution and irrigation management. Here are some key solutions offered by industrial valves for irrigation systems:

Gate Valves: Gate valves are commonly used in irrigation systems to control the flow of water in large pipes or channels. They offer reliable shut-off capabilities and are suitable for both on/off and throttling applications.

Butterfly Valves: Butterfly valves are ideal for regulating the flow of water in medium to large pipelines. Their quick operation and low-pressure drop make them suitable for irrigation systems requiring frequent adjustments or flow control.

Check Valves: Check valves prevent backflow in irrigation systems, ensuring that water flows in the desired direction and preventing damage to pumps, pipes, and other system components.

Pressure Reducing Valves: Pressure reducing valves maintain a constant and optimal pressure within the irrigation system, preventing damage to emitters, sprinklers, and other downstream components.

Remote-Control Valves: Remote-control valves enable automated operation and remote monitoring of irrigation systems, allowing for precise control of water flow and distribution based on real-time conditions and requirements.

Significance in Agricultural Water Management:

Industrial valves play a critical role in optimizing water distribution and management in irrigation systems, helping farmers maximize crop yields while minimizing water usage and waste. By providing precise control, reliable operation, and automation capabilities, industrial valves contribute to sustainable agriculture practices and efficient water resource management.

In conclusion, industrial valves are indispensable components of irrigation systems, offering solutions that optimize water distribution, enhance crop productivity, and promote sustainability in agricultural water management. Their role in controlling water flow, regulating pressure, and enabling automation underscores their significance in ensuring efficient and effective irrigation practices for farmers worldwide.

Related Products

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.

Pneumatic Globe Control Valve: A Comprehensive Guide

In modern industry, the Pneumatic Globe Control Valve is a highly efficient and precise fluid control device that is widely used in chemical, energy and heating systems. In this article, DELCO Valve will bring you a comprehensive understanding of this equipment from its working principle, characteristic advantages and application areas.

Electric Knife Gate Valve: Features, Applications and Selection Guide

In modern industry, Electric Knife Gate Valve is an important equipment in fluid control system. In this article, DELCO Valve will explain in detail its features and application areas to help you better understand and apply.

Electric Flange Butterfly Valve: A Comprehensive Guide

In industrial piping systems, Electric Flange Butterfly Valve is widely used in various fluid control scenarios. In this article, DELCO Valve will analyze its features, installation methods and application scenarios in detail, providing you with a complete reference guide.

Drinking Water Treatment Project

Industrial Valves Used For Drinking Water Treatment Project

The Drinking Water Treatment Project aims to ensure the provision of safe and clean drinking water to communities by treating raw water from various sources such as rivers, lakes, or groundwater. This project involves the implementation of advanced water treatment processes and technologies to remove impurities, pathogens, and contaminants from the water, making it suitable for consumption.

DELCO Valves Solutions

Industrial Valve Solution for Drinking Water Treatment Project:

In the Drinking Water Treatment Project, industrial valves play a crucial role in regulating the flow, pressure, and direction of water throughout the treatment process. Here are the solutions provided by industrial valves for this project:

Gate Valves: Gate valves are used for isolating sections of the pipeline during maintenance or repairs, ensuring seamless operation and minimal disruption to the treatment process.

Butterfly Valves: Butterfly valves are employed for throttling and controlling the flow of water in various treatment stages such as filtration, sedimentation, and disinfection. Their compact design and reliable performance make them ideal for use in water treatment facilities.

Check Valves: Check valves prevent backflow and ensure the unidirectional flow of water, maintaining the integrity of the treatment process and preventing contamination of the treated water.

Ball Valves: Ball valves are utilized for on/off control and flow regulation in critical points of the water treatment system, offering quick and precise operation to maintain process efficiency.

Pressure Reducing Valves: Pressure reducing valves help maintain optimal pressure levels within the water distribution system, safeguarding equipment and ensuring consistent water quality throughout the treatment process.

Control Valves: Control valves equipped with pneumatic or electric actuators enable precise modulation of flow rates and pressure, allowing operators to fine-tune the treatment parameters according to specific requirements.

By providing reliable and efficient flow control solutions, industrial valves contribute significantly to the success of Drinking Water Treatment Projects, ensuring the delivery of safe and clean drinking water to communities while adhering to stringent quality standards and regulations.

Related Products

Wastewater Treatment Project

Industrial Valves Used For Wastewater Treatment Project

The Wastewater Treatment Project is a crucial component of environmental protection and public health initiatives, aiming to treat and purify wastewater generated from various sources such as households, industries, and commercial establishments. The primary goal of this project is to remove pollutants, contaminants, and harmful substances from wastewater before it is discharged into the environment, ensuring minimal impact on water bodies and ecosystems.

DELCO Valves Solutions

Industrial Valve Solution for Wastewater Treatment Project:

Industrial valves play a vital role in the Wastewater Treatment Project by facilitating the control and management of wastewater flow, pressure, and direction throughout the treatment process. Here are the solutions provided by industrial valves for this project:

Gate Valves: Gate valves are used in wastewater treatment plants to isolate sections of the pipeline during maintenance or repairs, allowing for efficient and safe operation without interrupting the treatment process.

Butterfly Valves: Butterfly valves are employed for regulating the flow of wastewater in various treatment stages such as screening, sedimentation, and biological treatment. Their compact design and corrosion-resistant materials make them suitable for harsh wastewater environments.

Check Valves: Check valves prevent backflow and ensure the unidirectional flow of wastewater, preventing contamination of the treated water and maintaining the integrity of the treatment process.

Knife Gate Valves: Knife gate valves are specifically designed for handling slurries and viscous wastewater, providing reliable shut-off and control in applications such as sludge handling and dewatering.

Air Release Valves: Air release valves are installed in wastewater pipelines to automatically release trapped air and gases, preventing air pockets that can impede flow and efficiency in the treatment process.

Control Valves: Control valves equipped with pneumatic or electric actuators enable precise modulation of flow rates, pressure, and chemical dosing in wastewater treatment processes such as disinfection and pH adjustment, ensuring optimal treatment efficiency and compliance with regulatory standards.

By offering robust and reliable flow control solutions, industrial valves contribute significantly to the success of Wastewater Treatment Projects, allowing for the efficient and sustainable treatment of wastewater to protect the environment and public health.

Related Products

- Motorized Valve

- Pneumatic Valve

- Solenoid Valve

- Manual Valve

- Control valve

- Actuator