Tech Theory: Technical…Practical… Interesting Automation Industrial Solutions

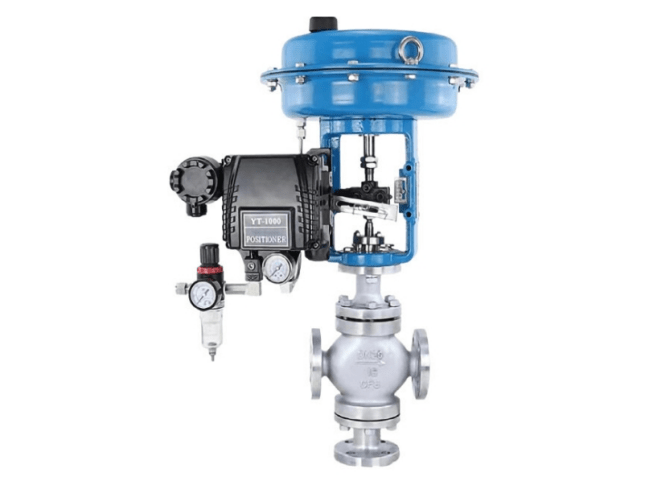

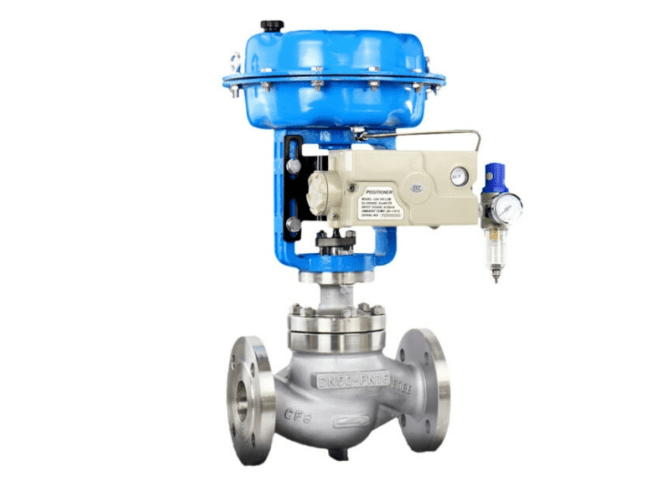

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control air supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Common solutions for faults in pneumatic control valves

1. Visual inspection

① Check whether the pneumatic control valve body and accessories are leaking or physically damaged.

② Verify the air source from the regulator to the locator/solenoid valve.

③ If there is no gas source, please open the isolation valve in the gas source manifold.

④ Confirm that the set pressure of the regulator matches the valve data sheet.

2. Air pressure check

Adjust the air pressure to the recommended level (low air pressure=slow movement of the pneumatic control valve, high air pressure=damaged actuator).

3. Power check

① Test valve movement using PLC/DCS commands.

② If there is no action, please check the power supply voltage and cable connections, including the fuses in the control cabinet.

③ Check the health condition of the cable; Replace the faulty wire pair.

4. Valve stroke and feedback inspection

① Use the 0-100% command to perform valve stroke check.

② Verify graphic feedback; Adjust settings or calibrate as needed.

5. Interlocking and permission inspection

If the valve stem does not move, please check if the PLC/DCS logic is interlocked or allowed.

6. Calibration

① If the travel issue persists, calibrate the pneumatic control valve.

② If the travel issue persists after calibration, please check the milliampere input of the locator.

7. Valve positioner inspection

If there are any questions about the function of the valve positioner, please replace the positioner; Re calibrate and check the travel.

8. Inspection of pneumatic control valve accessories

Check whether the quick exhaust valve, flow amplifier, manual valve, and exhaust port are blocked, and replace them if necessary. The method is direct air testing:

① If the problem persists, please remove the pipeline and directly load external air onto the actuator.

② Check if there are any issues with the actuator passing through; If necessary, conduct maintenance.

③ Apply air pressure to each workbench group and verify if the movement is smooth.

④ Check for failed actions.

How to get a quick quote for industrial valves?

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email marketing sales@delcofluid.com.

DELCO’s quality, competitive prices and excellent service make it the best valve partner to help you grow your business. Customize your valves, we have no minimum order.

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.