Tech Theory: Technical…Practical… Interesting Automation Industrial Solutions

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control air supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Disassembly steps for electric butterfly valves, electric ball valves, and electric two-way valves

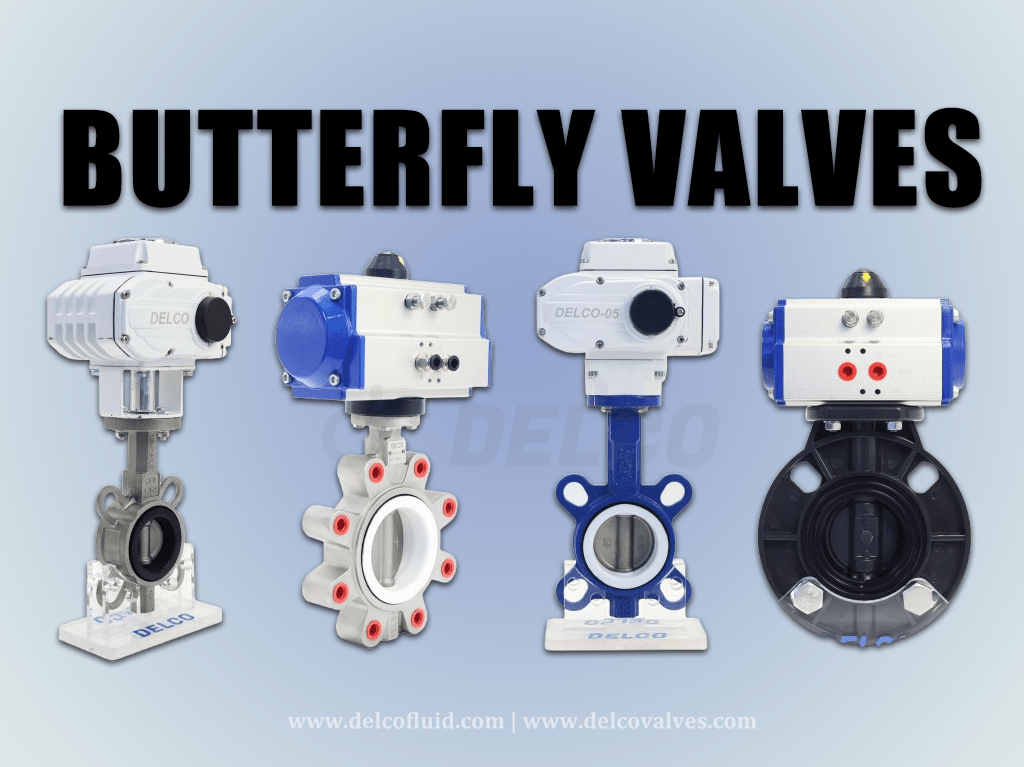

In the fields of industry and construction, the application of electric valves is widespread and crucial. Delcofluid valve manufacturers are well aware of the importance of proper disassembly for maintenance and upkeep of electric butterfly valves, electric ball valves, and electric two-way valves. Below, we will provide you with a detailed explanation of the disassembly steps for these three types of valves.

1、Disassembly steps of electric butterfly valve

Electric butterfly valves are known for their compact structure, easy operation, and superior sealing performance, and are widely used in water or ventilation systems in commercial buildings, public buildings, and urban pipelines. When disassembling, please follow the following steps:

(1) Power outage and exhaust: Firstly, ensure that the valve is powered off and close the upstream and downstream valves to release the pressure and residual medium in the pipeline.

(2) Disassemble the actuator: Use a tool to loosen the connecting bolt between the actuator and the valve body, and carefully separate the actuator from the valve body.

(3) Disassemble the valve stem and butterfly plate: Use a special tool to gently rotate the valve stem nut and extract the valve stem and butterfly plate assembly from the valve body.

(4) Inspection and Cleaning: Carefully inspect the wear of the valve seat, butterfly plate, and sealing ring, and replace them if necessary. At the same time, clean the inner wall of the valve body and all components to ensure no impurities remain.

2、Disassembly steps of electric ball valve

Electric ball valves play an important role in HVAC water systems due to their high-precision flow control and long-lasting sealing performance. When disassembling, please follow the steps below:

(1) Power outage and isolation: Similarly, ensure that the valve is powered off, close the upstream and downstream valves, and drain the pipeline.

(2) Dismantling flange or threaded connection: According to the connection method of the valve (flange or thread), use the corresponding tool to loosen the connection piece and separate the valve from the pipeline system.

(3) Remove valve core: Gently rotate the valve stem to remove the valve core from the valve body, taking care to protect the valve seat and sealing ring from damage.

(4) Maintenance and inspection: Check the wear of the valve core, valve seat, and sealing ring, and replace or repair them if necessary. Clean all components to ensure there are no impurities.

3、Disassembly steps for electric two-way valve

Electric two-way valves are widely used in temperature control of central air conditioning and heating systems due to their characteristics of spring reset, manual overload control, and easy wiring. When disassembling, please follow the following steps:

(1) Power outage and preparation: Ensure that the valve is powered off, close upstream and downstream valves, and release pipeline pressure.

(2) Dismantling the actuator: Use a screwdriver or other tool to carefully disassemble the actuator housing, exposing the internal transmission mechanism.

(3) Separate the valve stem and valve body: Gently rotate the valve stem nut to remove the valve stem and valve core assembly from the valve body.

(4) Inspection and maintenance: Check the wear of the valve core, valve seat, and sealing ring, and replace them if necessary. Clean all components to ensure no foreign objects remain.

(5) Recovery and testing: reassemble the valve in reverse order of disassembly and conduct functional testing to ensure that the valve is working properly.

Delcofluid valve manufacturers remind you to ensure that you fully understand the structural characteristics and disassembly steps of the valve before any disassembly work, and take corresponding safety measures to prevent accidents. At the same time, regular maintenance and upkeep of valves can greatly extend their service life and improve the overall operational efficiency of the system.

How to get a quick quote for industrial valves?

If you have questions about valves or want to get a quote, please feel free to contact us, we will reply within 6 hours. Phone +86 159 8960 2972, WhatsApp +86 159 8960 2972 or email marketing [email protected].

DELCO’s quality, competitive prices and excellent service make it the best valve partner to help you grow your business. Customize your valves, we have no minimum order.

At DELCO, we understand the importance of customer satisfaction and strive to meet the unique needs of every client. As a reliable control valve supplier, we are committed to providing excellent customer service and high-quality products to ensure optimal performance and longevity. By choosing DELCO as your trusted control valve supplier, you can benefit from customized valve assemblies designed specifically to meet your requirements, enhancing efficiency and reducing downtime.

Furthermore, our competitive pricing on electronic pressure regulators enables you to offer top-notch solutions. As one of the leading control valve manufacturers, we take pride in delivering reliable valves that not only meet industry standards but also contribute to the overall profitability of your business. By partnering with DELCO, you can have peace of mind knowing that you are making a wise choice for the long-term success of your company.